Japan, Matsumoto Kikai

Matsumoto Kikai BH-8DPa Pipe Ace

Product Made in Japan

Manufacturer : Matsumoto Kikai

Model : BH-8DPa

Features

●Various workpieces can be handled

It is also possible to handle various joints and special-shaped workpieces, expanding the fields of application. (workpieces with narrow pipe gaps, workpieces with short pipe sections, etc.)

● 100 items can be stored in memory

Welding conditions are stored as digital values, and welding can be performed stably simply by recalling and setting the conditions on the touch panel. Standard welding conditions (62 conditions *1 ) have been entered.

*1 Shield gas: Ar gas + H2 gas ( 5 %) mixed gas used

-USB memory function

Welding conditions (100 items) can be saved in USB memory by file, and welding conditions can be easily transferred to another control power supply (8DP).

● Standard printer function

Welding conditions can be printed out and retained as back data for welded workpieces, increasing reliability.

● Easy to carry

It is a compact and lightweight power supply, and can be carried easily by holding the handle, making it easy to move.

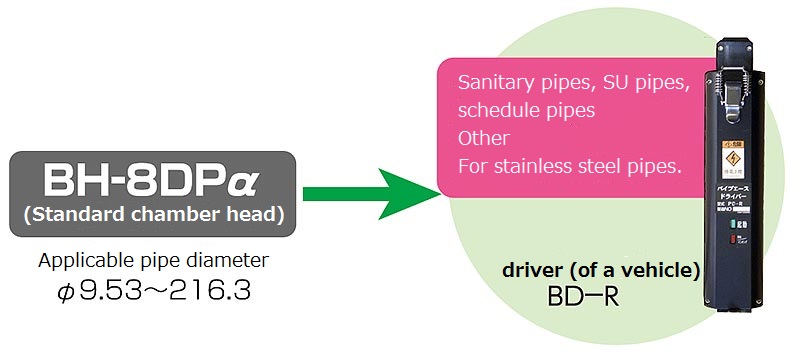

●Compatible with various fittings

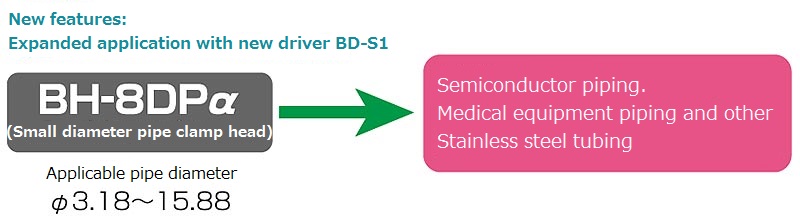

Pipe Ace BH-8DPα type (for stainless steel small diameter pipes)

| clamp head | BH-S | ||||

|---|---|---|---|---|---|

| |||||

| φ3.18〜φ15.88 | |||||

| Diameter (mm φ) | 3.18 | 6.35 | 9.53 | 12.7 | 15.88 |

| Nominal diameter designation | 1/8 | 1/4 | 3/8 | 1/2 | 5/8 |

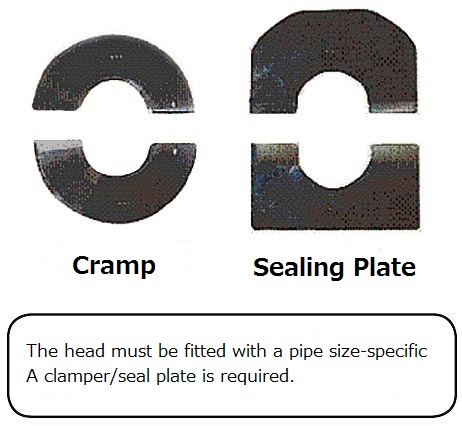

Note 1) Since it is a double-sided clamp type, tack welding of the tube is not required.

Note 2) Work positioning jig and electrode positioning jig are standard accessories.

| positioning jig | |

| For small diameter tube chamber head (standard accessory) | |

|

|

Standard Specifications

| model | BH-8DPα-220 | |

|---|---|---|

| Motor control method | – | encoder motor |

| Rated output current | A. | 220 (peak current) |

| Rated input voltage | V. | Single phase 200 |

| Rated input | kVA | 8.5 (5.0kW) |

| Rated frequency | Hz | 50/60 shared |

| Rated usage rate | % | 30% (180A) (10 minute cycle) |

| Number of welding condition setting areas | – | 16 areas |

| Welding condition setting factor (setting for each area) | – | Pulse current, base current, welding speed, welding time, direction of rotation, presence or absence of welding |

| Welding current adjustment range | A. | 3 to 220 |

| Welding time adjustment range | seconds | 1 to 999 |

| Welding speed adjustment range | mm/min | 50-200 (BD-S1: 300) |

| pulse frequency | Hz | 0.5 to 500 |

| pulse width | % | 10 to 85 |

| printer | – | date, welding conditions |

| internal memory | – | 100 conditions |

| external memory | – | USB (optional) |

| combination screwdriver | – | BD-R, BD-S1 (encoder motor) |

| External dimensions (width x depth x height) | mm | 400 x 255 x 525 (excluding handle) |

| mass | kg | 34 |

Note 1) Use the input voltage within the range of ±10% of the rated voltage.

Other than that, it cannot be used.

Note 2) External dimensions do not include handles.

Note 3) Speed may not be achieved depending on the combination of pipe diameter and driver.

Note 4) Fitting accuracy: Gap and unevenness should be 20% or less of the plate thickness.

Note 5) Low-sulfur (S content 0.005% or less) pipes are less prone to back-beading.

Note 6) Prepare a power supply facility capacity of 8.0kVA or more.

■ Spare parts and accessories

| tungsten electrode | – | φ2.4×150 1 piece |

|---|---|---|

| gas hose | m | φ8×5 |

| gas flow regulator | – | FR-2 (with left-hand screw attachment) |

| toolbox | – | Yamagata 300 |

| electrode gauge | – | 1.0mm, 1.2mm, 1.5mm, 2mm |

| hex screwdriver | mm | 1.5 (for electrode replacement) 2.0, 3.0 (for head clamper) |

| hose band | – | 2 pieces |

| glass tube fuse | A. | 3 |

| Electrode polishing holder | – | 1 |

| screw set | – | 1 bag |

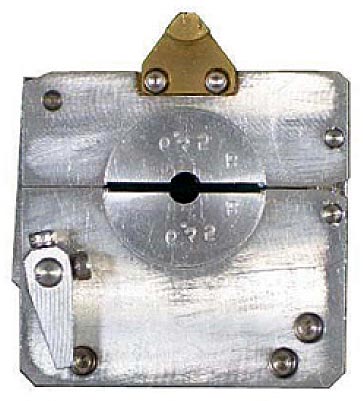

■ Welding head

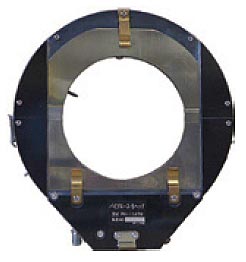

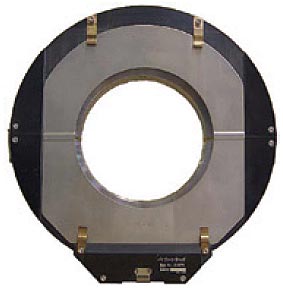

| model | Standard chamber head | small tube clamp head | |||||

|---|---|---|---|---|---|---|---|

| 25TA | 50TW | 76TW | 114TW | 216TW | BH-S1 | ||

| Applicable pipe diameter | φ mm | φ9.53〜φ25.4 _ | φ19.05〜φ50.8 _ | φ22.2〜φ76.3 _ | φ28.5〜φ114.3 _ | φ114.3〜φ216.3 _ | φ3.18〜φ15.88 _ |

| Clamp fee | mm | 30 | 41 | 56 | 18 | ||

| Minimum pipe spacing (wall to wall) | mm | 40 | 70 | 80 | 90 | 115 | 30 |

| Rated current | A. | 40 | 70 | 30 | |||

| Rated usage rate | % | 20 | Air cooling: 40 Water cooling: 60 | 20 | |||

| Head cooling method | – | air cooling | Water cooling clamper ring | air cooling | |||

| External dimensions (width x depth x height) | mm | 96×102×56 | 153×158×61 | 195×198×61 | 220×224×61 | 340×338×90 | 65×35×64 |

| mass | kg | 0.7 | 1.7 | 2.2 | 2.6 | 7.2 | 0.6 |

Note 1) Rated usage rate indicates when using the minimum applicable diameter pipe for each welding head.

Note 2) External dimensions do not include handles.

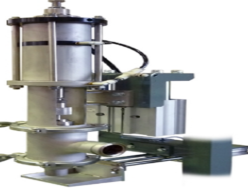

■ Cooling water circulation system

| model | MP-250B | |

|---|---|---|

| Rated input voltage | V. | 200 (single-phase 50/60Hz shared) |

| Discharge pressure | MPa | 0.36/0.42 |

| Exhaust heat | kW | 2.4 |

| tank capacity | liter | 6.5 |

| External dimensions (width x depth x height) | mm | 266×480×385 |

| mass | kg | Approx. 17 (Approx. 24 when full) |

| BH-114TW | BH-216TW | ||||||||||||||||||||||||||||

|  |  |  |  | |||||||||||||||||||||||||

| Applicable pipe size | φ9.53〜φ25.4 | φ19.05〜φ50.8 | φ22.2 to φ76.3 | φ28.5〜φ114.3 | φ114.3〜φ216.3 | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stainless steel pipe (JIS G3459) | Diameter (mm φ) | 10.5 | 13.8 | 17.3 | 21.7 | 21.7 | 27.2 | 34.0 | 42.7 | 48.6 | 27.2 | – | 34.0 | 42.7 | 48.6 | 60.5 | 76.3 | 34.0 | 42.7 | 48.6 | 60.5 | 76.3 | 89.1 | 101.6 | 114.3 | 114.3 | 139.8 | 165.2 | 216.3 |

| Nominal diameter designation | 6A | 8A | 10A | 15A | 15A | 20A | 25A | 32A | 40A | 20A | – | 25A | 32A | 40A | 50A | 65A | 25A | 32A | 40A | 50A | 65A | 80A | 90A | 100A | 100A | 125A | 150A | 200A | |

| 1/8B | 1/4B | 3/8B | 1/2B | 1/2B | 3/4B | 1B | 1-1/4B | 1/1/2B | 3/4B | – | 1B | 1-1/4B | 1/1/2B | 2B | 2 1/2B | 1B | 1-1/4B | 1/1/2B | 2B | 2 1/2B | 3B | 3-1/2B | 4B | 4B | 5B | 6B | 8B | ||

| Stainless steel sanitary pipe (JIS G3447) | Diameter (mm φ) | – | – | – | 25.4 | – | 25.4 | 31.8 | 38.1 | 50.8 | 25.4 | 31.8 | – | 38.1 | 50.8 | 63.5 | 76.3 | 31.8 | 38.1 | 50.8 | 63.5 | 76.3 | 89.1 | 101.6 | 114.3 | 114.3 | 139.8 | 165.2 | – |

| Nominal diameter designation | – | – | – | 1S | – | 1S | 1/1/4S | 1/1/2S | 2S | 1S | 1/1/4S | – | 1/1/2S | 2S | 2 1/2S | 3S | 1/1/4S | 1/1/2S | 2S | 2 1/2S | 3S | 3 1/2S | 4S | 4 1/2S | 4 1/2S | 5 1/2S | 6S | – | |

| SU pipe (stainless steel pipe) (JIS G3447) | Diameter (mm φ) | 9.53 | 12.7 | 15.88 | 22.22 | 22.22 | 28.58 | 34.0 | 42.7 | 48.6 | 22.2 | 28.59 | 34.0 | 42.7 | 48.6 | 60.5 | 76.3 | 34.0 | 42.7 | 48.6 | 60.5 | 76.3 | 89.1 | – | 114.3 | 114.3 | 139.8 | 165.2 | 216.3 |

| Nominal diameter designation | 8SU | 10SU | 13SU | 20SU | 20SU | 25SU | 30SU | 40SU | 50SU | 20SU | 25SU | 30SU | 40SU | 50SU | 60SU | 75SU | 30SU | 40SU | 50SU | 60SU | 75SU | 80SU | – | 100SU | 100SU | 125SU | 150SU | 200SU | |

Pipe Ace BH-8DPα type (for stainless steel small diameter pipes)