Japan, MAXPULL

Maxpull mini max pull winch

Made in Japan

Manufacturer: Maxpull

Model: PM-100 type/PM-200 type

Features

A lightweight and compact mini winch developed for light work for personal use. Not suitable for heavy industrial work. For raising and lowering banners, setting nets for tennis and volleyball, installing jet skis in vehicles, etc.

Easy operability

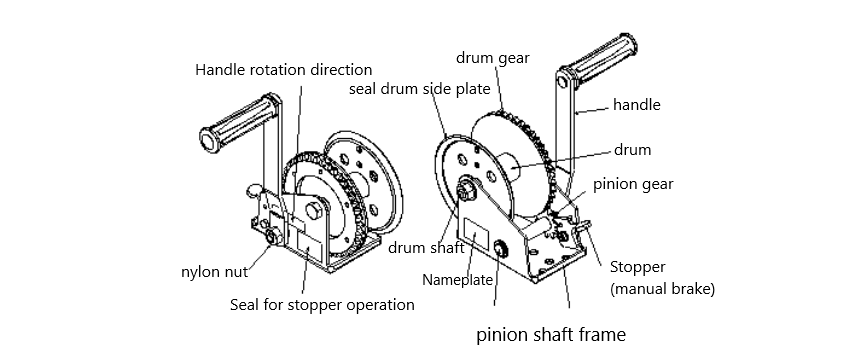

Due to its high mechanical efficiency, the manual load during operation is very light compared to winches manufactured by other companies, making work easier. The compact design makes it lightweight and very convenient to carry. In addition, the body can be easily fixed with the prescribed bolts. Another great feature is that each part is made by press processing, and the whole is assembled with bolts, so it can be easily disassembled. Even in the case of repair, anyone can easily repair and assemble by simply purchasing the parts and following the instruction manual.

The PM-100 type brake is a manual (claw) brake.

The pawl can be rotated while winding up, but remove the pawl when winding down. (When removing the claw, hold the handle with your hand, or do it when there is no load.) To work safely, turn the handle in the direction of the sticker attached to the side of the frame. Wind the wire rope correctly. When the handle is rotated clockwise in the winding direction, the drum rotates counterclockwise. If it is wound up at this time, it is in the correct state. Be sure to secure at least 5 rolls of waste rolls for the drum.

The PM-200 type brake is an automatic mechanical brake.

Turning the handle in the winding direction (counterclockwise) makes a clicking sound, and turning the handle in the winding down direction (counterclockwise) makes no sound. Repeat this operation 3 to 4 times, and the mechanical brake is working properly if you can hear a clicking sound every time you turn it in the hoisting direction. Wind the wire rope correctly by turning the handle in the winding direction indicated by the sticker attached to the clutch cover. When the handle is rotated clockwise in the winding direction, the drum rotates counterclockwise. If it is wound up at this time, it is in the correct state. Be sure to secure at least 5 rolls of waste rolls for the drum.

Precautions for handling

Do not use the PM-100 type for lifting a load vertically. The PM-100 type is a manual brake. The pawl can be rotated while the pawl is engaged, but the pawl must be removed when unwinding. (When removing the claw, hold the handle with your hand, or do it when there is no load.) PM-200 and above have a built-in mechanical automatic brake (clockwise to wind up and counterclockwise to wind down). It will stop even if you release your hand.)

Specifications

| Model | PM-100 type | PM-200 type |

| wire rope tensile force | 980N (100kgf) Below each standard layer |

1960N (200kgf) Below each standard layer |

| Wire rope capacity | φ3mm×40.0m (12-layer winding) φ4mm×25.0m (9-layer winding) φ5mm×15.5m (5-layer winding) |

φ4mm×25.0m (9-layer winding) φ5mm×15.5m (7-layer winding) φ6mm×11.5m (6-layer winding) |

| Deceleration ratio | 1/4.1 | 1/4.1 |

| Handle operating force | φ3mm : 58N(5.9kgf) : 8th layer standard (Trap 22.5m) φ4mm : 57N(5.8kgf) : 6th layer standard (Trap 14.0m) φ5mm : 58N(5.9kgf) : 5th layer standard (Involving amount 9.5m) |

φ4mm : 114N(11.6kgf) : 6th layer standard (Trap 14.0m) φ5mm : 115N(11.7kgf) : 5th layer standard (Trap 9.5m) φ6mm : 111N(11.3kgf) : 4th layer standard (Crawling amount 6.0m) |

| handle length | 205mm | 205mm |

| Weight (Body + Handle) | 2.7kg | 3.3kg |

An example of a Mini Max Pull winch usage site