Drilling And Cutting, Hand Tools, Japan, Miyakawa

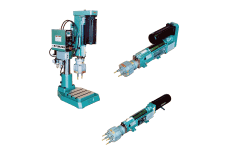

Miyakawa AF Air Type Multi-axis Drill

Product Made in Japan

Manufacturer: Miyakawa

Model: AF1-111, AF2 – 125, AF1-112, AF2 – 126.

AF1-111 Air type drill unit (motor directly connected type)

|

Features

|

Control unit, multi-axis attachment is sold separately.

Dimensional drawing

| A | B | C | D | E | F | G | H | J | K | N | O | Main shaft end taper | |

| AF 1-111 | 775 | twenty five | twenty five | twenty five | 140 | 132 | 278 | 42 | 65 | Ten | 162 | 102 | JT No. 1 |

Performance specification

| Drilling ability (mild steel) Maximum | mm | φ 6 | |

| Shaft end shape | JT | No.1 | |

| Main spindle full stroke | mm | 80 | |

| Cutting feed stroke maximum | mm | 50 | |

| Minimum required fast forward stroke | mm | 30 | |

| ※ 1 Main spindle speed | 50 Hz | min-1 | 5000, 3300, 2250, 1500, 1000 |

| 60 Hz | min-1 | 6000, 4000, 2700, 1800, 1200 | |

| Cutting feed speed | mm / sec | 0.4 / 20 | |

| Thrust (when air pressure is 0.5 MPa) | N | 1000 | |

| Regular air pressure | MPa | 0.5 | |

| Drive motor | 3 phase – 2 P – 200 W | ||

| weight | kg | 14 | |

| Spindle type for ashlessable adapter | Present | ||

* 1 The speed change pulley is not included in the price of the machine body |

|||

Standard accessories

| Hexagonal wrench wrench | Two |

| Poly V belt | One |

| Supply hydraulic fluid | 25 cc |

| One end mouth wrench | One |

| instruction manual | 1 book |

Notes

- To operate this machine, please use air source with capacity according to usage conditions.

- When using, please indicate the number of rotation in the table.

- Spindle for Adjustable Adapter is made to order.

AF2 – 125 Air type drill unit (motor directly connected type)

|

Features Integrate body and base

|

Control unit, multi-axis attachment is sold separately.

Dimensional drawing

| A | B | C | D | E | F | G | H | J | K | N | O | Main shaft end taper | |

| AF 2-125 | 915 | 40 | 33 | 27 | 125 | 268 | 282.5 | 60 | 70 | 12 | 205 | 145 | JT No. 6 |

Performance specification

| Drilling ability (mild steel) Maximum | mm | φ9 | |

| Shaft end shape | JT | No. 6 | |

| Main spindle full stroke | mm | 120 | |

| Cutting feed stroke maximum | mm | 90 | |

| Minimum required fast forward stroke | mm | 30 | |

| ※ 1 Main spindle speed | 50 Hz | min-1 | 4170, 2960, 2080, 1500, 1050, 750 |

| 60 Hz | min-1 | 5000, 3550, 2500, 1800, 1250, 900 | |

| Cutting feed speed | mm / sec | 0.4 ~ 20 | |

| Thrust (when air pressure is 0.5 MPa) | N | 1500 | |

| Regular air pressure | MPa | 0.5 | |

| Drive motor | 3 phase -2 P – 375 W | ||

| weight | kg | 28 | |

| Spindle type for ashlessable adapter | Present | ||

* 1 The speed change pulley is not included in the price of the machine body |

|||

Standard accessories

| Hexagonal wrench wrench | 3 |

| Poly V belt | One |

| Supply hydraulic fluid | 25 cc |

| One end mouth wrench | One |

| instruction manual | 1 book |

Notes

- To operate this machine, please use air source with capacity according to usage conditions.

- When using, please indicate the number of rotation in the table.

- Spindle for Adjustable Adapter is made to order.

AF1-112 Air type drill unit (motor folding type)

|

Features Integrate body and base

|

Control unit, multi-axis attachment is sold separately.

Dimensional drawing

| A | B | C | D | E | F | G | H | J | K | N | O | Main shaft end taper | |

| AF1-112 | 506 | twenty five | twenty five | twenty five | 140 | 130 | 278 | 42 | 65 | Ten | 252 | 192 | JT No. 1 |

Performance specification

| Drilling ability (mild steel) Maximum | mm | φ 6 (φ 8) | |

| Shaft end shape | JT | No.1 | |

| Main spindle full stroke | mm | 80 | |

| Cutting feed stroke maximum | mm | 50 | |

| Minimum required fast forward stroke | mm | 30 | |

| ※ 1 Main spindle speed | 50 Hz | min-1 | 5000, 3300, 2250, 1500, 1000, 650 |

| 60 Hz | min-1 | 6000, 4000, 2700, 1800, 1200, 800 | |

| Cutting feed speed | mm / sec | 0.4 ~ 20 | |

| Thrust (when air pressure is 0.5 MPa) | N | 1000 | |

| Regular air pressure | MPa | 0.5 | |

| Drive motor | 3 phase – 2 P – 200 W | ||

| weight | kg | 15 | |

| Spindle type for ashlessable adapter | Present | ||

* 1 The speed change pulley is not included in the price of the machine body |

|||

Standard accessories

| Hexagonal wrench wrench | Two |

| Poly V belt | One |

| Supply hydraulic fluid | 25 cc |

| One end mouth wrench | One |

| instruction manual | 1 book |

Notes

- To operate this machine, please use air source with capacity according to usage conditions.

- When using, please indicate the number of rotation in the table.

- Spindle for Adjustable Adapter is made to order.

AF2 – 126 Air type drill unit (motor folding type)

|

Features Integrate body and base

|

Control unit, multi-axis attachment is sold separately.

Dimensional drawing

| A | B | C | D | E | F | G | H | J | K | N | O | Main shaft end taper | |

| AF 2-126 | 646 | 40 | 33 | 27 | 125 | 270 | 282.5 | 60 | 70 | 12 | 296 | 236 | JT No. 6 |

Performance specification

| Drilling ability (mild steel) Maximum | mm | φ9 | |

| Shaft end shape | JT | No. 6 | |

| Main spindle full stroke | mm | 120 | |

| Cutting feed stroke maximum | mm | 90 | |

| Minimum required fast forward stroke | mm | 30 | |

| ※ 1 Main spindle speed | 50 Hz | min-1 | 4170, 2960, 2080, 1500, 1050, 750 |

| 60 Hz | min-1 | 5000, 3550, 2500, 1800, 1250, 900 | |

| Cutting feed speed | mm / sec | 0.4-20 | |

| Thrust (when air pressure is 0.5 MPa) | N | 1500 | |

| Regular air pressure | MPa | 0.5 | |

| Drive motor | 3 phase -2 P – 375 W | ||

| weight | kg | 31 | |

| Spindle type for ashlessable adapter | Present | ||

* 1 The speed change pulley is not included in the price of the machine body |

|||

Standard accessories

| Hexagonal wrench wrench | 3 |

| Poly V belt | One |

| Supply hydraulic fluid | 25 cc |

| One end mouth wrench | One |

| instruction manual | 1 book |

Notes

- To operate this machine, please use air source with capacity according to usage conditions.

- When using, please indicate the number of rotation in the table.

- Spindle for Adjustable Adapter is made to order.

AF option

control unit

|

The controller consists of a pneumatic control unit (air unit and air valve) and an electric control unit (control box), so you can operate immediately if you connect it to this unit.

|

|

Multi-axis drill unit with controller

|

|

Multi-axis drill unit with controller

|

Step controller (special order)

|

Step feed function (Since the main body structure is different, when ordering, write S after AF model) (Example AF 2 – 126 S type)

The cutting feed can be intermittently fed by setting the timer time. This improves the discharge of chips and prevents breakage of tools caused by chips. |

|

Multi-axis drill unit with step controller Example

|

Spindle type for ashlessable adapter (custom-made)

|

AF1 All models of AF2 have this type.

Adjustable adapter [φ16 × 1 (AF 1) φ 19 × 1 (AF 2)] can be mounted on the spindle end, which is extremely convenient when aligning the dimensions to the tip of the tool such as when polishing or replacing the drill. |

Other

| Speed change pulley | The pulley set described in each AF unit specification table |

|---|---|

| Special belt | For 750/900 rotation of AF2 for 650/800 rotation of AF1 |

| Drill chuck | JT No. 1 1 mm – 8 mm (for AF 1 standard type) JT No. 6 1 mm – 13 mm (for AF 2) |

Table stand

|

The figure combines the table stand with the standard type directly connected model and the control unit. |

|

|

| A | B | Tap unit (for QT) | |

| For AF1 | 775 | 1220 | QT-1 |

| For AF2 | 915 | 1360 | QT-2 |

AF unit capacity chart (reference)

Drilling capacity · Drill diameter by shaft number (mm)

Supply air pressure 0.5 MPa

| Model | Main shaft rotation speed | Steel (S45C) | Cast iron (FC 200) | Aluminum (A1100) | |||||||||

| 1 axis | 2 axes | 3 Axis | 4 axes | 1 axis | 2 axes | 3 Axis | 4 axes | 1 axis | 2 axes | 3 Axis | 4 axes | ||

| AF1 | 800 | 8 | 4 | 3 | 2.5 | 10 | 5 | 3.5 | 3.5 | 10 | 5 | 3.5 | 3.5 |

| 1200 | 6 | 3 | 2.5 | 2 | 8 | 4 | 3.5 | 3 | 8 | 4 | 3.5 | 3 | |

| 1800 | 4 | 2.5 | 2 | 1.5 | 6 | 3.5 | 3 | 2 | 6 | 3.5 | 3 | 2 | |

| 2700 | 3 | 2 | 1.5 | 4 | 2.5 | 2 | 4 | 3 | 2 | ||||

| 4000 | 2 | 1.5 | 3 | 2 | 3 | 2 | |||||||

| 6000 | 1 | 2 | 2 | ||||||||||

| AF2 | 900 | 9 | 6 | 5 | 4 | 11 | 7 | 5.5 | 4.5 | 12 | 7 | 5.5 | 4.5 |

| 1250 | 7 | 5.5 | 4 | 3 | 9 | 6 | 5 | 3.5 | 10 | 6 | 5 | 3.5 | |

| 1800 | 6 | 5 | 3 | 2 | 7 | 5.5 | 3.5 | 2.5 | 9 | 5.5 | 3.5 | 2.5 | |

| 2500 | 5 | 4 | 2.5 | 6 | 4.5 | 3 | 6 | 4.5 | 3 | ||||

| 3550 | 3 | 2.5 | 4 | 3 | 5 | 3 | |||||||

| 5000 | 2 | 3 | 3 | ||||||||||

Related Products

-

EagleJack G-60LC Hydraulic Jack with Claw

-

Shinano SI-4730 Saw Standard Air Tools

-

UHT CORPORATION 2Head 2Stage Laser Puncher LP-2S□D series Laser

-

Kondotec MS Series Ship’s Steel Guy Blocks With Swivels For Fiber Ropes

-

NDV Rubber lining diaphragm valves with excellent corrosion and chemical resistance

-

Vessel No. 6300 “CRYSTALINE” Screwdriver