Drilling And Cutting, Hand Tools, Japan, Miyakawa

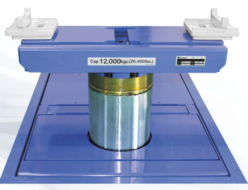

Miyakawa G Type Multi-axis Drill

Product Made in Japan

Manufacturer: Miyakawa

Model: G type

G type

| Features

|

| |

| |

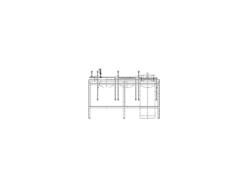

Geometry

| ability | L1 | L3 | ||||

| C-6 | C-10 | C-13 | MT-1 | MT-2 | MT-3 | |

| J For 13 mm | 140.5 | 156.5 | 196 | 219 | – | – |

| For 2M 19 mm | 137.5 | 153.5 | 193 | 216 | 232 | – |

| For 3M 32 mm | 156.5 | 172.5 | 222 | 245 | 261 | 321 |

| For 4M 40 mm | 137.5 | 153.5 | 193 | 216 | 232 | 292 |

| For 5M 60 mm | 162.5 | 178.5 | 218 | 241 | 257 | 317 |

G type ear with bracket

Features

|

|  |

Dimension table

| Model | Size |  | |||

| C | D | S | φG | ||

| G-1320 With ears | 130 | 200 | 260 | 25 | |

| G-1326 with ears | 130 | 260 | 320 | 25 | |

| G-1332 with ears | 130 | 320 | 380 | 25 | |

| G-1620 With ears | 160 | 200 | 260 | 30 | |

| G-1626 with ears | 160 | 260 | 320 | 30 |  |

| G-1632 with ears | 160 | 320 | 380 | 30 | |

| G-1640 with ears | 160 | 400 | 470 | 35 | |

| G-2030 with ears | 200 | 300 | 370 | 35 | |

| G-2040 with ears | 200 | 400 | 470 | 35 | |

| G-2050 with ears | 200 | 500 | 580 | 40 | |

| G-2530 with ears | 250 | 300 | 370 | 35 | |

| G-2540 With ears | 250 | 400 | 470 | 35 |  |

| G-2550 with ears | 250 | 500 | 580 | 40 | |

| G-2020 with ears | 200 | 200 | 260 | 30 | |

| G-2525 with ears | 250 | 250 | 320 | 35 | |

| G-2828 With ears | 280 | 280 | 350 | 35 | |

| G-3232 with ears | 320 | 320 | 400 | 40 | |

| G-3636 with ears | 360 | 360 | 440 | 40 | |

G type (rectangular) performance specification

| Model | Types and names ofchucks | Scope of hole processing | Outer dimension of multi-axis head | Rigidity range per axis | Maximum grip diameter ofchuck(mm) | Weight with 4 axes(kg) | ||||

| A (vertical) (mm) | B (Horizontal) (mm) | Minimum axis range between two axes(mm) | C (vertical) (mm) | D (Horizontal) (mm) | Drilling capacity (iron) S45C (mm) | Tap ability (iron) S45C (M) | ||||

| G-1320 | C-6 | 86 | 156 | 15 | 130 | 200 | 5 | 5 | 6 | 11.2 |

| C-10 | 80 | 150 | 23 | 8 | 6 | 10 | 11.5 | |||

| C-13 | 70 | 140 | 36 | 10 | 8 | 13 | 17.7 | |||

| MT-1 | 10 | 8 | 14 | 18.5 | ||||||

| G-1326 | C-6 | 86 | 216 | 15 | 130 | 260 | 5 | 5 | 6 | 12.8 |

| C-10 | 80 | 210 | 23 | 8 | 6 | 10 | 13.2 | |||

| C-13 | 70 | 200 | 36 | 10 | 8 | 13 | 19.9 | |||

| MT-1 | 10 | 8 | 14 | 20.7 | ||||||

| G-1332 | C-6 | 86 | 276 | 15 | 130 | 320 | 5 | 5 | 6 | 14.3 |

| C-10 | 80 | 270 | 23 | 8 | 6 | 10 | 14.6 | |||

| C-13 | 70 | 260 | 36 | 10 | 8 | 13 | 21.9 | |||

| MT-1 | 10 | 8 | 14 | 22.7 | ||||||

| G-1620 | C-6 | 116 | 156 | 15 | 160 | 200 | 5 | 5 | 6 | 12.5 |

| C-10 | 110 | 150 | 23 | 8 | 6 | 10 | 12.9 | |||

| C-13 | 100 | 140 | 36 | 10 | 10 | 13 | 19.4 | |||

| MT-1 | 13 | 12 | 14 | 20.7 | ||||||

| G-1626 | C-6 | 116 | 216 | 15 | 160 | 260 | 5 | 5 | 6 | 14.3 |

| C-10 | 110 | 210 | 23 | 8 | 6 | 10 | 14.6 | |||

| C-13 | 100 | 200 | 36 | 10 | 10 | 13 | 21.9 | |||

| MT-1 | 13 | 12 | 14 | 22.7 | ||||||

| G-1632 | C-6 | 116 | 276 | 15 | 160 | 320 | 5 | 5 | 6 | 16.2 |

| C-10 | 110 | 270 | 23 | 8 | 6 | 10 | 16.5 | |||

| C-13 | 100 | 260 | 36 | 10 | 10 | 13 | 24.7 | |||

| MT-1 | 13 | 12 | 14 | 25.5 | ||||||

| G-1640 | C-6 | 116 | 356 | 15 | 160 | 400 | 5 | 5 | 6 | 19.1 |

| C-10 | 110 | 350 | 23 | 8 | 6 | 10 | 19.4 | |||

| C-13 | 100 | 340 | 36 | 10 | 10 | 13 | 28.6 | |||

| MT-1 | 13 | 12 | 14 | 29.4 | ||||||

| G-2030 | C-6 | 156 | 256 | 15 | 200 | 300 | 5 | 5 | 6 | 18.2 |

| C-10 | 150 | 250 | 23 | 8 | 6 | 10 | 18.5 | |||

| C-13 | 140 | 240 | 36 | 10 | 10 | 13 | 27.2 | |||

| MT-1 | 13 | 12 | 14 | 28.0 | ||||||

| MT-2 | 130 | 230 | 38 | 22 | 16 | 23 | 29.8 | |||

| MT-3 | 120 | 220 | 56 | 30 | 22 | 32 | 36.0 | |||

| G-2040 | C-10 | 150 | 350 | 23 | 200 | 400 | 8 | 6 | 10 | 22.8 |

| C-13 | 140 | 340 | 36 | 10 | 10 | 13 | 33.0 | |||

| MT-1 | 13 | 12 | 14 | 33.8 | ||||||

| MT-2 | 130 | 330 | 38 | 22 | 16 | 23 | 35.8 | |||

| MT-3 | 120 | 320 | 56 | 30 | 22 | 32 | 43.5 | |||

| G-2050 | C-10 | 150 | 450 | 23 | 200 | 500 | 8 | 6 | 10 | 25.7 |

| C-13 | 140 | 440 | 36 | 10 | 10 | 13 | 37.7 | |||

| MT-1 | 13 | 12 | 14 | 38.4 | ||||||

| MT-2 | 130 | 430 | 38 | 22 | 16 | 23 | 41.7 | |||

| MT-3 | 120 | 420 | 56 | 30 | 22 | 32 | 51.4 | |||

| G-2530 | C-10 | 200 | 250 | 23 | 250 | 300 | 8 | 6 | 10 | 21.4 |

| C-13 | 190 | 240 | 36 | 10 | 10 | 13 | 31.4 | |||

| MT-1 | 13 | 12 | 14 | 32.1 | ||||||

| MT-2 | 180 | 230 | 48 | 22 | 16 | 23 | 35.2 | |||

| MT-3 | 170 | 220 | 56 | 30 | 22 | 32 | 42.8 | |||

| G-2540 | C-10 | 200 | 250 | 23 | 250 | 400 | 8 | 6 | 10 | 25.7 |

| C-13 | 190 | 240 | 36 | 10 | 10 | 13 | 37.7 | |||

| MT-1 | 13 | 12 | 14 | 38.4 | ||||||

| MT-2 | 180 | 230 | 48 | 22 | 16 | 23 | 41.7 | |||

| MT-3 | 170 | 220 | 56 | 30 | 22 | 32 | 51.4 | |||

| G-2550 | C-10 | 200 | 250 | 23 | 250 | 500 | 8 | 6 | 10 | 32.4 |

| C-13 | 190 | 240 | 36 | 10 | 10 | 13 | 46.0 | |||

| MT-1 | 13 | 12 | 14 | 46.7 | ||||||

| MT-2 | 180 | 230 | 48 | 22 | 16 | 23 | 50.1 | |||

| MT-3 | 170 | 220 | 56 | 30 | 22 | 32 | 61.2 | |||

G type (square) performance specification

| Model | Types and names ofchucks | Scope of hole processing | Outer dimension of multi-axis head | Rigidity range per axis | Maximum grip diameter ofchuck(mm) | Weight with 4 axes(kg) | ||||

| A (vertical) (mm) | B (Horizontal) (mm) | Minimum axis range between two axes(mm) | C (vertical) (mm) | D (Horizontal) (mm) | Drilling capacity (iron) S45C (mm) | Tap ability (iron) S45C (M) | ||||

| G-2020 | C-6 | 156 | 156 | 15 | 200 | 200 | 5 | 5 | 6 | 14.9 |

| C-10 | 150 | 150 | 23 | 8 | 6 | 10 | 15.2 | |||

| C-13 | 140 | 140 | 36 | 10 | 10 | 13 | 22.5 | |||

| MT-1 | 13 | 12 | 14 | 23.3 | ||||||

| G-2525 | C-10 | 200 | 200 | 23 | 250 | 250 | 8 | 6 | 10 | 19.2 |

| C-13 | 190 | 190 | 36 | 10 | 10 | 13 | 28.3 | |||

| MT-1 | 13 | 12 | 14 | 29.1 | ||||||

| MT-2 | 180 | 180 | 48 | 22 | 16 | 23 | 32.0 | |||

| MT-3 | 170 | 170 | 56 | 30 | 22 | 32 | 34.5 | |||

| G-2828 | C-10 | 230 | 230 | 23 | 280 | 280 | 8 | 6 | 10 | 21.9 |

| C-13 | 220 | 220 | 36 | 10 | 10 | 13 | 32.1 | |||

| MT-1 | 13 | 12 | 14 | 32.9 | ||||||

| MT-2 | 210 | 210 | 48 | 22 | 16 | 23 | 36.0 | |||

| MT-3 | 200 | 200 | 56 | 30 | 22 | 32 | 43.8 | |||

| G-3232 | C-10 | 270 | 270 | 23 | 320 | 320 | 8 | 6 | 10 | 26.1 |

| C-13 | 260 | 260 | 36 | 10 | 10 | 13 | 38.2 | |||

| MT-1 | 13 | 12 | 14 | 39.0 | ||||||

| MT-2 | 250 | 250 | 48 | 22 | 16 | 23 | 42.3 | |||

| MT-3 | 240 | 240 | 56 | 30 | 22 | 32 | 52.0 | |||

| G-3636 | C-10 | 310 | 310 | 23 | 60 | 360 | 8 | 6 | 10 | 31.0 |

| C-13 | 300 | 300 | 36 | 10 | 10 | 13 | 45.2 | |||

| MT-1 | 13 | 12 | 14 | 46.0 | ||||||

| MT-2 | 290 | 290 | 48 | 22 | 16 | 23 | 49.6 | |||

| MT-3 | 280 | 280 | 56 | 30 | 22 | 32 | 61.6 | |||

Related Products

-

TONE RD10S Ratchet Screwdriver Set

-

DIJET EXSKS Series High Feed Machine Cutter

-

SUGIYASU WTSL15 Mid Size Truck Lift

-

Chiyoda Seiki Cylinder Collection Device For Liquid Qxygen/nitrogen/argon And Liquid Carbon Dioxide Parallel Type Cylinder Collection Device

-

Arimitsu FB Type Pressure Washer / High Pressure Jet Cleaners (Motor Type)

-

Kunimoto 0708005 ALCWall Attachment