Cutting, Nissan Tanaka

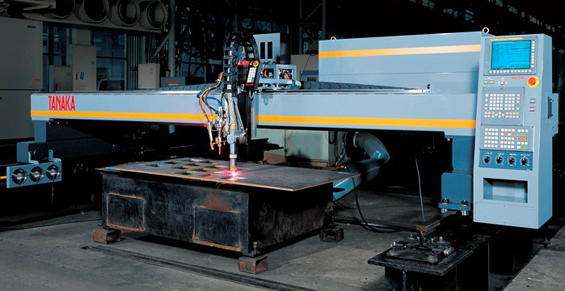

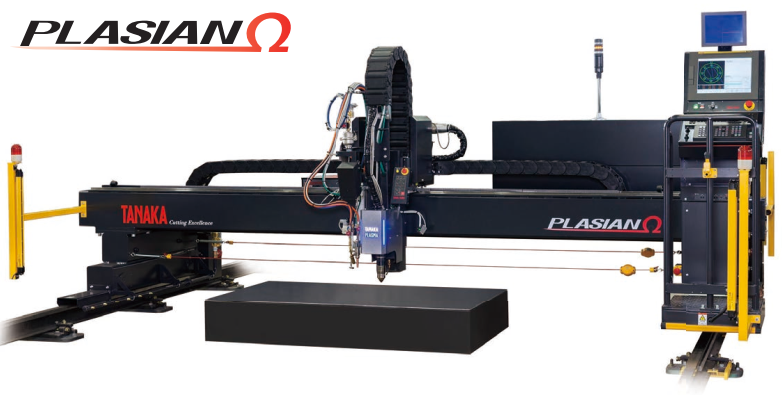

NISSAN TANAKA PLASIAN Ω Plasma Cutting Machine

Manufacturer: Nissan Tanaka

Model: PLASIAN Ω

Have a plasma high-speed in all the cutting sites !

This is the newest and most powerful plasma cutting machine with not only cutting speed but also body feed speed and piercing speed increased. Rapid speed and high efficiency inherent in the shearing press are now compatibly available in the plasma machine. With high precision and high quality, mild steel plates of 6-32 mm in thickness can be cut by the lightweight machine body, high-speed drive system, the newest and optimized NC device and the high-quality plasma cutting apparatus. Optionally, devices for cutting 6-50mm steels (mild steel, vertical) and for cutting 6-25 mm stainless steels (vertical) are also available.

Equipment configuration

| Cutting machine body | 1 set |

|---|---|

| Plasma cutting apparatus, HPR260-S | 1 set |

| NC device, FANUC FS-0iMF Plus | 1 set |

| Cooling water circulating device (included in plasma power source) | 1 set |

Equipment configuration

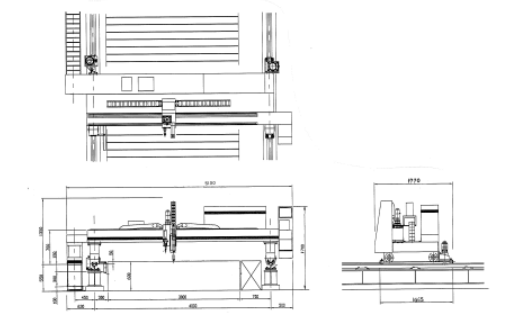

| Model | 20R | 25R | 30R | 35R | 40R |

|---|---|---|---|---|---|

| Effective cutting range (mm) | 2,100 | 2,600 | 3,100 | 3,600 | 4,100 |

| Rail span (mm) | 3,000 | 3,500 | 4,000 | 4,500 | 5,000 |

| Rail size (mm) | 37/kg *Standard: 9,600 Rail length can be extendable as per 1,200 | ||||

| Effective cutting length (mm/min) | Standard: 7,200 (Total length -2,400) | ||||

| Plasma power source | XPR300/XPR170 | ||||

| Machining feed speed (mm) | 0 – 10,000 | ||||

| Rapid feed speed (mm/min) | 30,000 *OP(Hi-Rapid Feed Speed: 50,000) | ||||

| Marking speed (mm/min) | 24,000 | ||||

| Up-down-stroke (mm) | Standard: 200 | ||||

| NC device | FANUC FS-0iMF Plus | ||||

| Total length of machine (mm) | 2,435 | ||||

| Total high of machine (mm) | 1,829 from Rail Top | ||||

| Lead-in system | Cable veyor system (the hanger system is also available) | ||||

Utility:

Input power supply capacity (Machine body: 10KVA, Plasma power supply: 70KVA)

Fluid to be used (Oxygen: 0.8MPa, 80L/min, Air: 0.8MPa, 70L/min, Water: to be supplied as necessary)

Standard equipped articles

- Vertical cutting torch block

- Plasma torch collision mitigating device

- Arc standoff sensor + initial height sensing (Nozzle touch sensing) Intrusion preventive sensor (Photoelectric tube safety device)

- Rotary lamp (Three colors)

- Coordinate rotation function (With laser spot projector)

- Scheduled operation function

- Fume blow-off fan

- Plasma-exclusive screen (Main screen)

※The following are displayed on the LCD screen: Auto-run time, piercing time and number of times, drafting display, cutting condition screen display, etc.

Optional specification:

- Operator’s deck

- Z-marking device

- Dust collector (Stand-alone type)

- Pegasus 500- O (500A) plasma cutting apparatus (for cutting mild steel of 6-50mm, with dross-free up to 40mm)

- HPR260-S plasma cutting apparatus (for cutting SUS of 6-25mm)

Saitama factory is equipped with ISO 9001 certification. ISO 9001 certification number: 99QR • 156

Scope of registration: Design and manufacture of oxy-fuel, plasma and laser cutting machines.

Always read the “Instruction manual” thoroughly for proper operation. The specification is subject to change without notice.

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka