Japan, Nitta

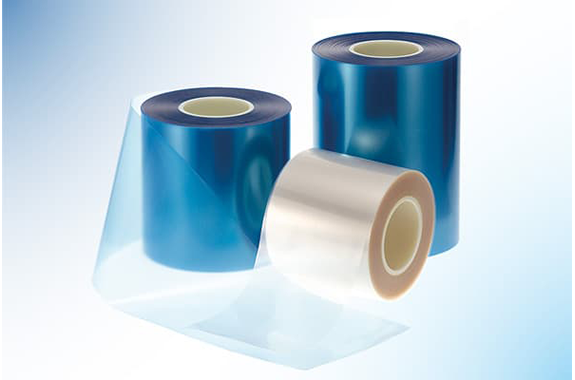

Nitta Wax-Substitute Type Intelimer™Tape

Product Made in Japan

Manufacturer: Nitta

Model: Wax-Substitute Type

WAX-SUBSTITUTE TYPE

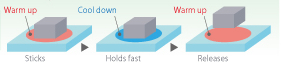

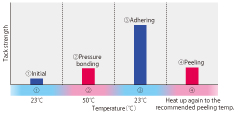

- Bonds at the switching temperature and above, and holds fast when cooled below that.

- Can be peeled off if heated up to above the switching temperature again.

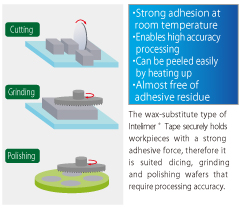

- Strong tack strength improves processing accuracy.

The wax-substitute type holds fast, thus minimizing displacement in processes that apply pressure to workpieces and improving processing accuracy. Because the tape holds fast, it is suited for dicing electronics and grinding/polishing wafers as they undergo microfabrication.

HOW TO USE

- Peel the separator from one side of the tape. Since the tape is not adhesive at room temperature, heat it to around 50ºC with a hot plate or other heat source to trigger its adhesion. Process the workpiece while bonded to the tape.

- When the tape and workpiece are restored to room temperature,the tackiness increases whereby bonding the two.

- Process the workpiece while bonded to the tape.Use for application in the range of room temperature to 60ºC.( Heat resistance varies with the product type.)

- To peel the tape after the work, heat up the workpiece and tape again, and peel the tape from the workpiece.

Peel off the tape at above th switching temperature.If restored to room temperature at this point, tackiness increases whereby making the tape harder to peel off.( Peel the TS44 type at 100ºC or above.)

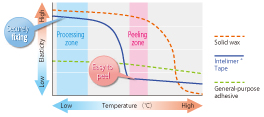

Comparison of elastic modulus

Tack strength vs. temperature

PRECAUTIONS FOR USE

- Affixing the tape

This tape becomes tacky when heated up to 50ºC or above, but tackiness varies with temperature or pressure. Therefore, test the tape before actual use. - Peeling the tape

This tape readily releases when reheated, but its release depends on bonding conditions. Also, stripping the tape off forcefully can damage the target surface or leave glue residue on it.

SPECIFICATION

| Product code | Switching temp. | Surface delamination strength※1 (Intelimer™ adhesive) N/25mm | Bottom delamination strength※1 (General-purpose adhesive) N/25mm | Tape thickness (No separators) | Base (PET) thickness | Remarks |

| SC4210CB3 | 45℃ | 9.0 | 5.0 | 120μm | 100μm | Double-sided type |

| SC4210CB8 | 6.0 | |||||

| SC4210CB4 | 1.5 | |||||

| TS4440NL2 | 80〜130℃ | 6.0 | - | 40μm | - | Baseless type |

※1:Compliant with JIS Z0237

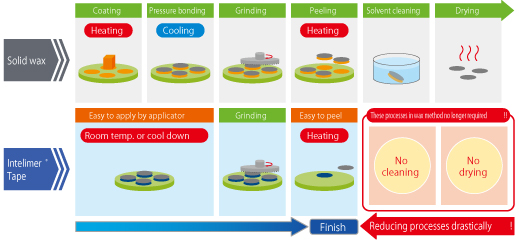

Advantages of Changing from Wax to Intelimer™ Tape

Reducing processes

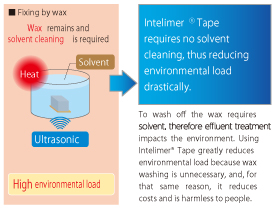

Using Intelimer™ Tape lets manufacturers omit solvent washing and drying processes required with the conventional wax anchoring method.

Reducing environmental load

Main applications

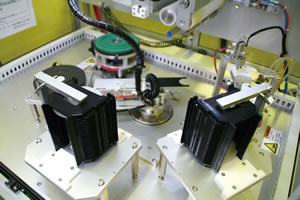

Intelimer™ Tape Applicator TCM-460

Applicator proposal

This device automatically applies Intelimer™ Tape to sapphire and other material wafers. It can be added to existing production lines in place of conventional wax coating machines with minimal changes to other equipment. And, it eliminates costs associated with washing.

| ●Appearance of tape applicator | ●Automatic application by roller | ●Reducing tact time by parallel processing |

|  |  |