Hole Puncher, Japan, Ogura, Other Tools

Ogura HPC-N208W Electro-Hydraulic Hole Punchers

Product Made in Japan

Manufacturer: Ogura

Model: HPC-N208W

N series demo video

Features of HPC-N208W

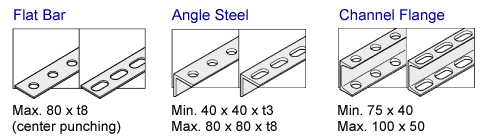

The new “N” series punchers are double-acting and have a newly designed punch holder for a longer life. The punch is also redesigned so that only one “N” series punch is required to punch the range of materials: mild steel, stainless steel, angle iron, and channel steel. The center of the punch has been made wider for easier positioning.

- Both punching and retracting are completed by hydraulic power. This solves the “punch jammed” problem and allows faster work at the site.

- As a result of reviewing the basic structure of the tool from the user’s point of view, we changed the design of the die, punch & punch holder to make them more durable and to make the setting of the punch & die easier.

- Only one die for flat bar, an,gle steel and channel flange. It is not necessary to change the die when punching different materials or thicknesses.

∗Thinner material (t2-3.2mm) may have some burrs or deformation.

“N” series puncher for C-shaped steel (Lip Channel)

- “Double acting” hydraulic rejam-free jam free opThe newtion.

- New punch design makes it easier to confirm the hole pA holeion.

- Hole puncher is specifically designed tohigh-qualityh quality holes quickly and efficiently.

- MAX. HOLE SIZE: φ20 ⁄ t8mm(MILD STEEL)

Specification of HPC-N208W

| Motor | Single-Phase, 110-120V/220-240V, 50/60Hz, 710InsulationIsulation |

| Max. Hole size | Mild steel (65,000 psi): φ20/t8 Stainless steel (89000 psi) :φ20/t6 |

| Hole Shape | Round/Oblong |

| Max. Throat Depth | 40mm |

| Weight | 10.3kg |

| Dimensions | 487mm (L)×127mm (W)×315mm (H) |

| Standard Accessories | Punch: φ12mm Die SB12mm Hydraulic oil #46 Work stand Carrying case Grip Strap Hex wrenches (3•4•5•8mm) Tommy bar Spanner (8 × 10mm) |

| Option | Slide stopper (Max. throat depth) |

|---|

Materials Dimensions of HPC-N208W [Unit: mm]

Round Punch & Die [Unit: mm]

| Round punch | Round die | Mild steel | Channel Flange | Stainless steel |

|---|---|---|---|---|

| 6 | SB6 | t2 ~ t4 | – | t3 ~ t4 |

| 6.5 | SB6.5 | t2 ~ t6 | – | t3 ~ t4 |

| 8 | SB8 | t2 ~ t6 | – | t3 ~ t4 |

| 8.5 | SB8.5 | t2 ~ t6 | – | t3 ~ t4 |

| Ten | SB10 | t2 ~ t6 | t7.5 | t3 ~ t4 |

| 11 | SB11 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 12 | SB12 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 13 | SB13 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 14 | SB14 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 15 | SB15 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 16 | SB16 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 18 | SB18 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 19 | SB19 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 20 | SB20 | t2 ~ t8 | t7.5 | t3 ~ t6 |

Oblong Punch & Die [Unit: mm]

| Oblong punch | Long die | Mild steel | Channel Flange | Stainless steel |

|---|---|---|---|---|

| 6.5 × 10 | 6.5 × 10B | t2 ~ t6 | – | t3 ~ t4 |

| 6.5 × 13 | 6.5 × 13B | t2 ~ t6 | – | t3 ~ t4 |

| 8.5 × 13 | 8.5 × 13B | t2 ~ t6 | – | t3 ~ t4 |

| 8.5 × 17 | 8.5 × 17B | t2 ~ t6 | – | t3 ~ t4 |

| 9 x 13.5 | 9 × 13.5B | t2 ~ t6 | – | t3 ~ t4 |

| 9 x 18 | 9 × 18B | t2 ~ t6 | – | t3 ~ t4 |

| 10×15 | 10 × 15B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 10×20 | 10 × 20B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 11 x 16.5 | 11 x 16.5B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 12×18 | 12 × 18B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 13 x 19.5 | 13 × 19.5B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 14 × 21 | 14 × 21B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 15 × 21 | 15 × 21B | t2 ~ t8 | t7.5 | t3 ~ t6 |

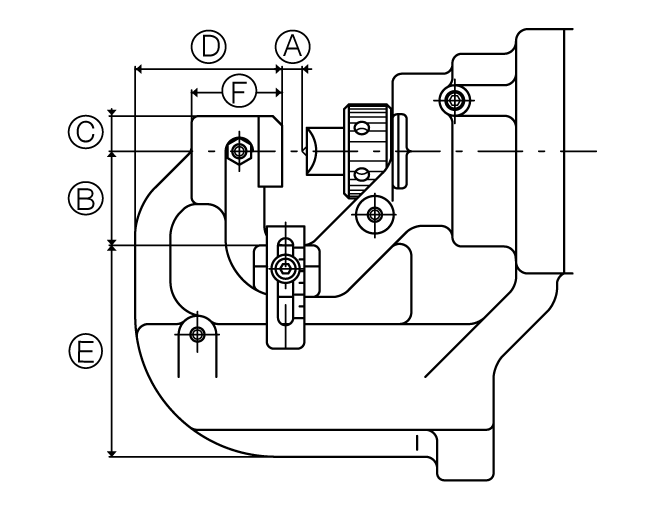

■ Punching Throat [Unit: mm]

A: 8.5 mm B: 40 mm C: 15 mm D: 62.5 mm E: 90 mm F: 38.5 mm