Bending, Japan, Ogura, Other Tools

Ogura MB-L16 Portable Rebar Bending Machine

Product Made in Japan

Manufacturer: Ogura

Model: MB-L16

Features of MB-L16

- Achieves a table surface height of 183mm. Easier to place reinforcing bars on the table, further improving workability.

- Equipped with a new shock absorber, the durability has been greatly improved by significantly improving the recoil and impact sound when the roller returns.

- Easy dial dialing is used to set the basic bending angle.

- In addition, the angle can be adjusted more finely when used in combination with the fine adjustment lever.

- Adopts a “partition wall structure” that does not allow iron powder that can cause failure to enter.

- Each size roller/collar is standard equipment.

- D10 and D13 “small” bend radius processing is also supported by the right angle bend collar (sold separately).

Specification of MB-L16

| Motor | Single phase 100V 1050W 50 / 60Hz |

| Mass | 24.0kg |

| Body dimensions | 388 (L) x 365 (W) x 229 (H) mm |

| Maximum/minimum bending radius | For SD345 D8 (R31 to R10), D16 (R31 to R19) |

| Bending speed | 180 ° bending (approximately 3.0 seconds) |

| Number bent at a time | D16 (1), D13 (2), D10 (3) |

| Bending ability | Rebar diameter D8 ~ D16 (SD345 equivalent: 490N / mm 2 ( 50kgf / mm 2 )) |

| Bending angle range | 4 steps up to 180 ° (with fine adjustment function) |

| Standard accessories | Roller (No.B16, No.B13, No.B10), Collar (No.B16, No.B13, No.B10), Hexagon wrench (8), Grounding adapter, Tool box |

| Option | Foot switch, body stand, right angle collar, auxiliary table |

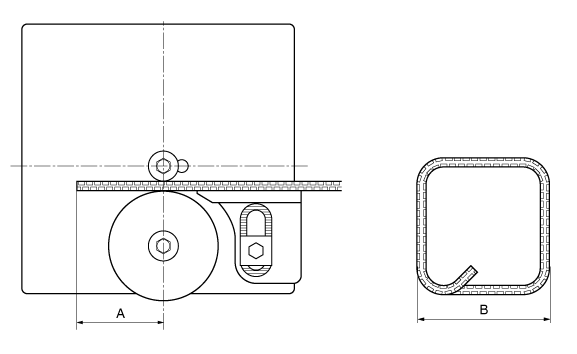

R & C TABLE (How to combining Roller and Collar)

Minimum necessary length of bending

Combination of Roller and Collar

| Rebar diameter | Roller | Collar | A dimension (minimum) | ||

|---|---|---|---|---|---|

| 90 ° bend | 135 ° bending | 180 ° bending | |||

| D10 | B10 (Φ88) | B10 (Φ38) | 65mm | 84mm | 103mm |

| D13 | B13 (Φ70) | B13 (Φ50) | 80mm | 105mm | 130mm |

| D16 | B16 (Φ52) | B16 (Φ62) | 95mm | 126mm | 157mm |

| Rebar diameter | Collar | B dimension (minimum) |

|---|---|---|

| D10 | B10 (Φ38) | 118mm |

| D13 | B13 (Φ50) | 136mm |

| D16 | B16 (Φ62) | 154mm |

Related Products

-

Okazaki Seiko SEE5GA Coated Solid Carbide Endmills (GO-RIKI MILL) (5 Flutes)

-

Kanetec KPM SMALL PLATE MAGNET

-

Nikkin Flux Gamma Radiation Measuring Instrument PMT Sensors

-

TSURUMI PUMP PARTS: PACKING NEW PART NUMBER 121-002-09 Parts & Accessories

-

Obishi Keiki Seisakusho Granite Arm Type Surface Plate ( Stationary )

-

Watanabe WGP-AZ AC converter – Signal Converter