Japan, Orientalmotor

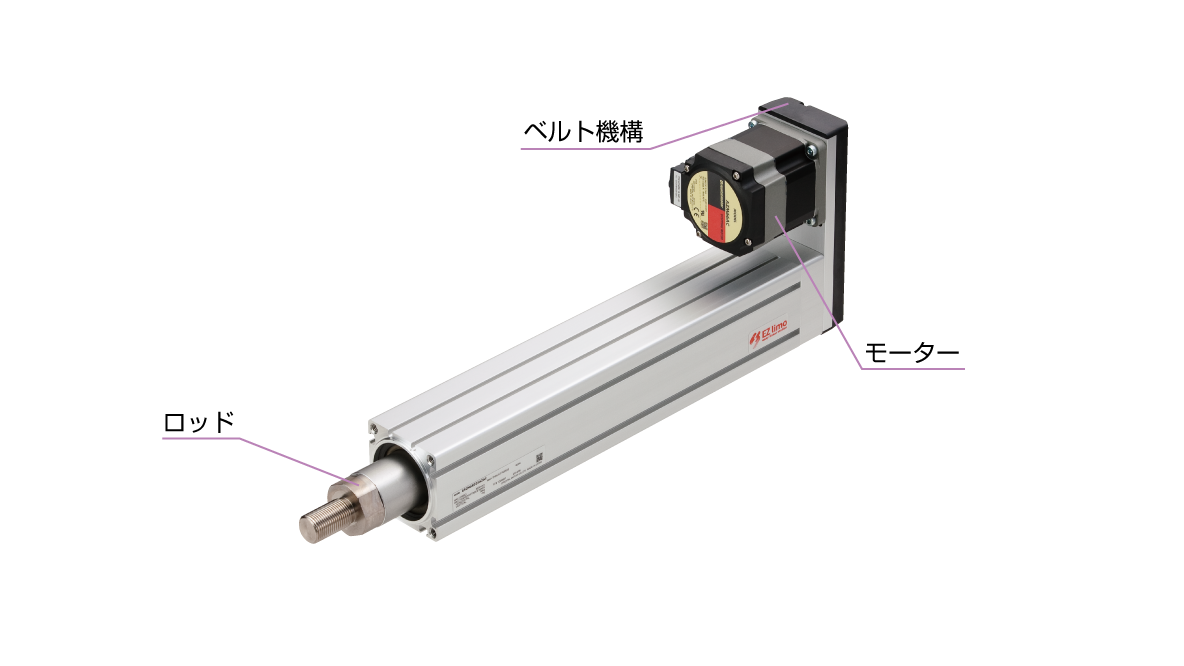

Orientalmotor EAC Series Electric Cylinder

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: EAC Series

Features

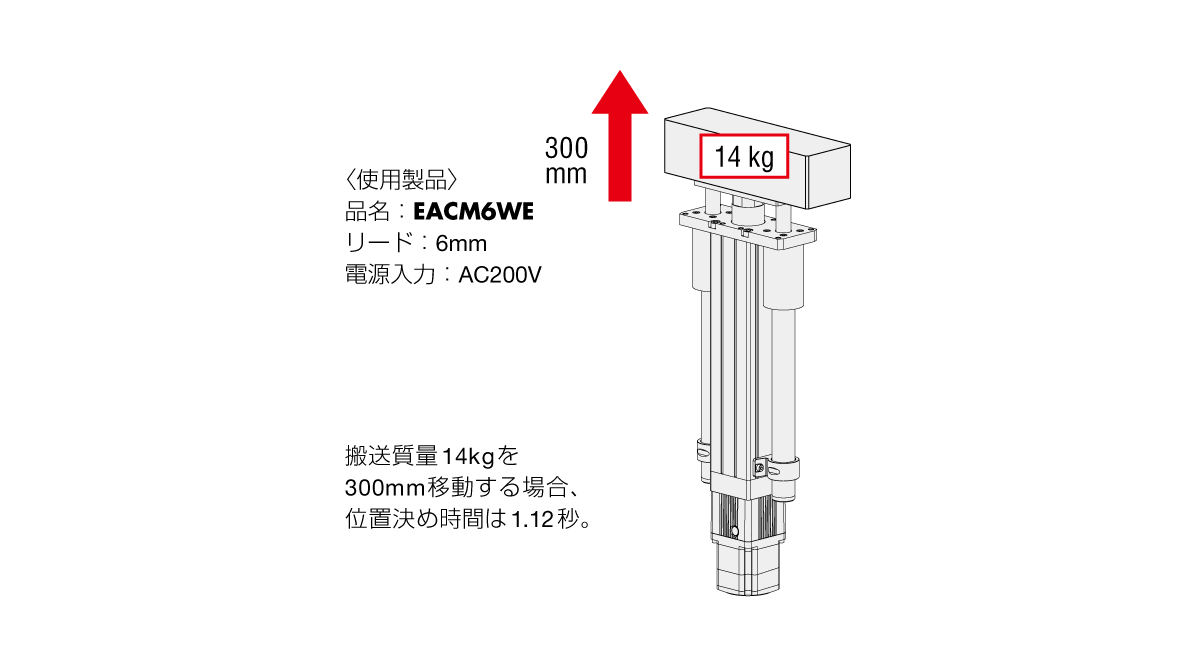

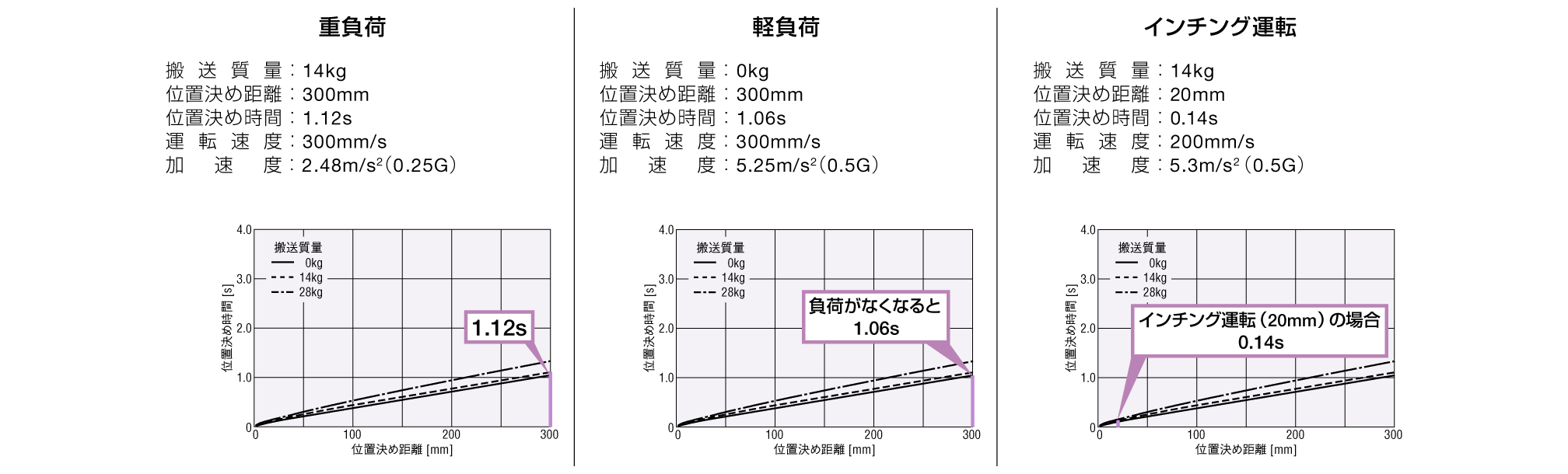

High speed drive possible from light load to heavy load

For EACM6 type

We have prepared a support tool that can calculate the approximate positioning time for applicable our electric actuator products according to the “model” and “operating conditions.”

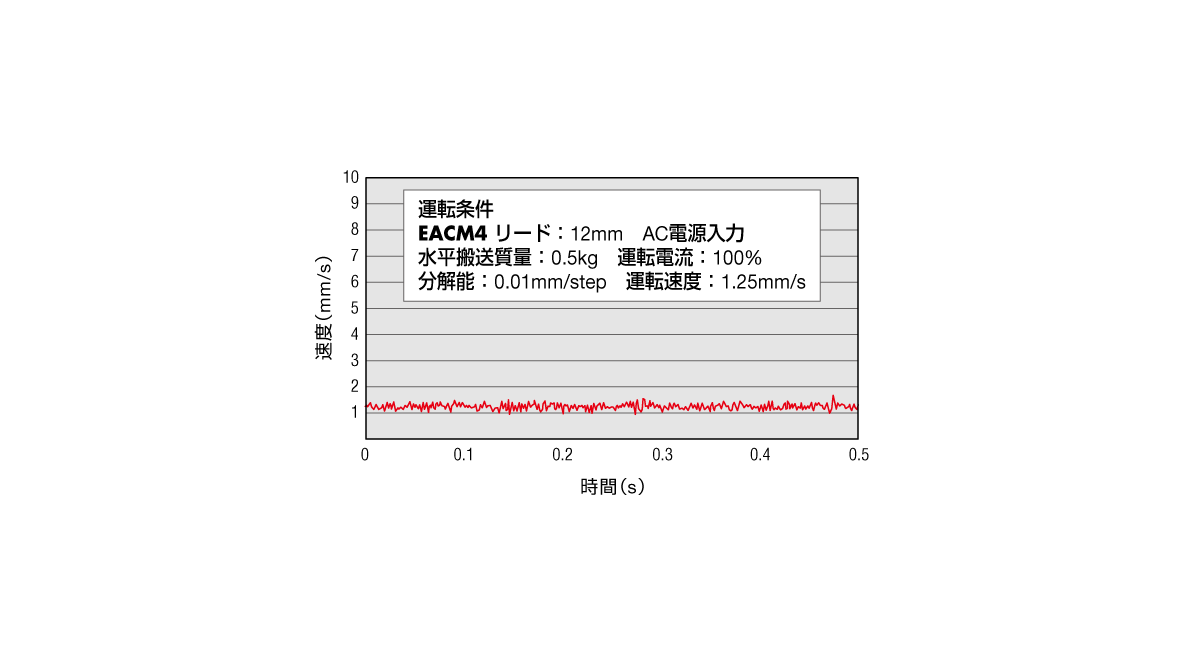

Stable movement with little speed fluctuation even at low speeds

The micro-step drive of the closed-loop stepping motor allows for increased resolution without the need for mechanical elements such as a reduction mechanism

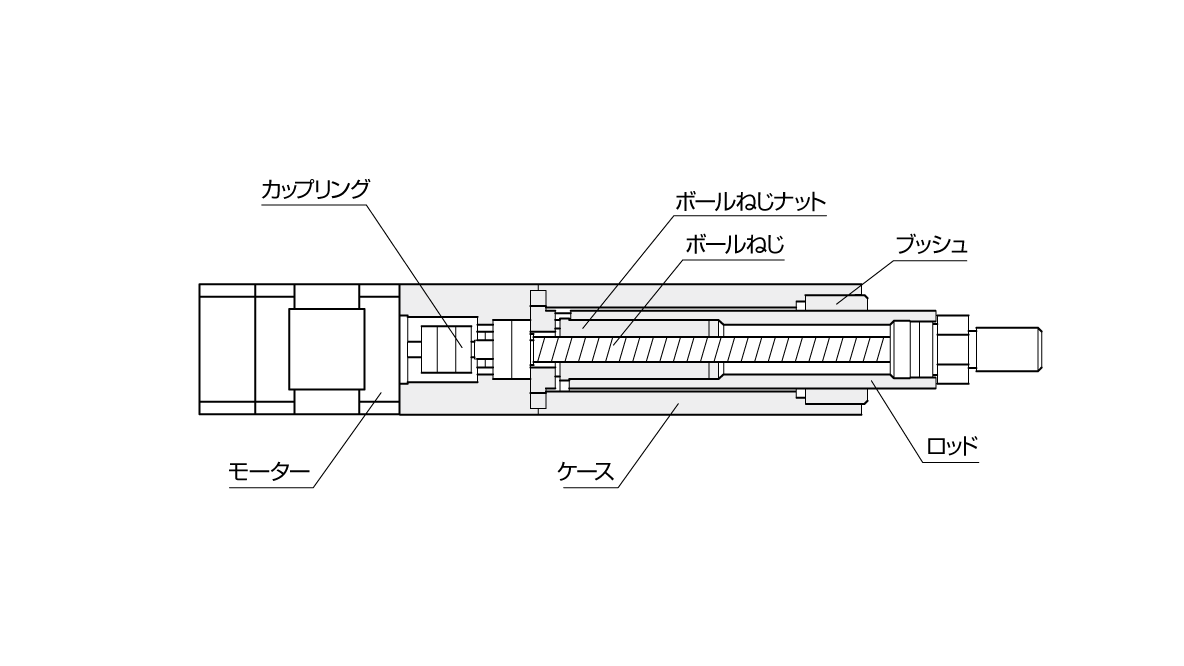

Small and high thrust cylinder

This electric cylinder uses aluminum for the rod, and is small, lightweight, yet powerful.

Its vibration suppression structure improves acceleration characteristics and enables high-speed positioning.

Wide variety of cylinders

Line up

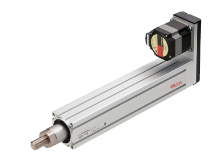

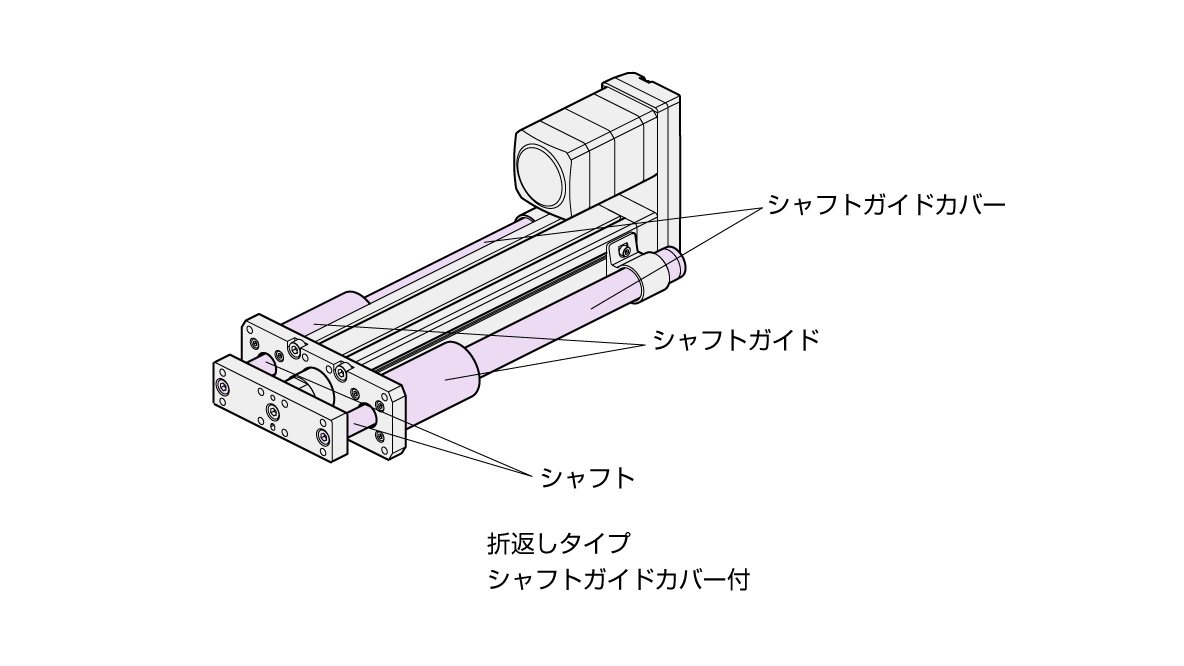

In addition to the straight type, the EAC series also offers a folded type.Furthermore, each type is available in three cylinder shapes: without a shaft guide, with a shaft guide, and with a shaft guide cover.

| Shaft Guide | Straight Type | Bent Type |

| No Shaft Guide You need an external guide to align with your device. |  |  |

With Shaft Guide Eliminates the need for customers to design and procure external guides, contributing to a reduction in equipment startup time. |  |  |

With Shaft Guide Cover Protects the moving parts on the cylinder body side, improving device safety. It also helps prevent grease scattering from the shaft guide and foreign matter from entering the linear bushing. |  |  |

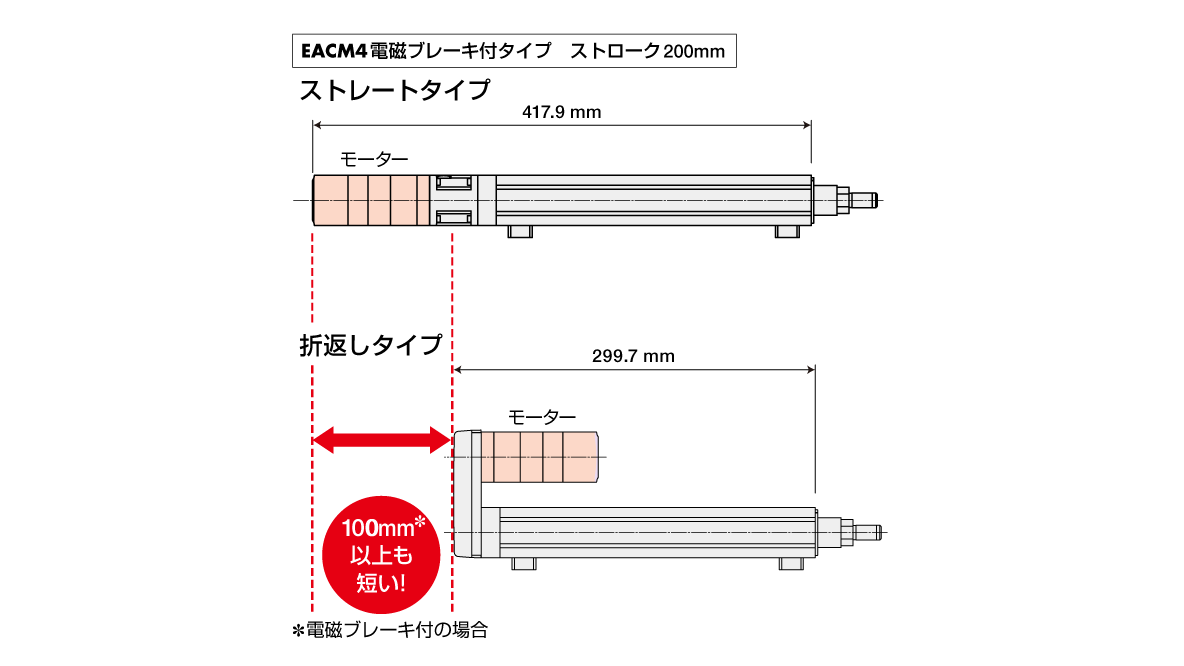

Contributes to space saving (folded type)

Folding Type

A belt mechanism folds back the motor mounting direction.

All models are available with a folded motor type, which shortens the overall length and contributes to space saving.

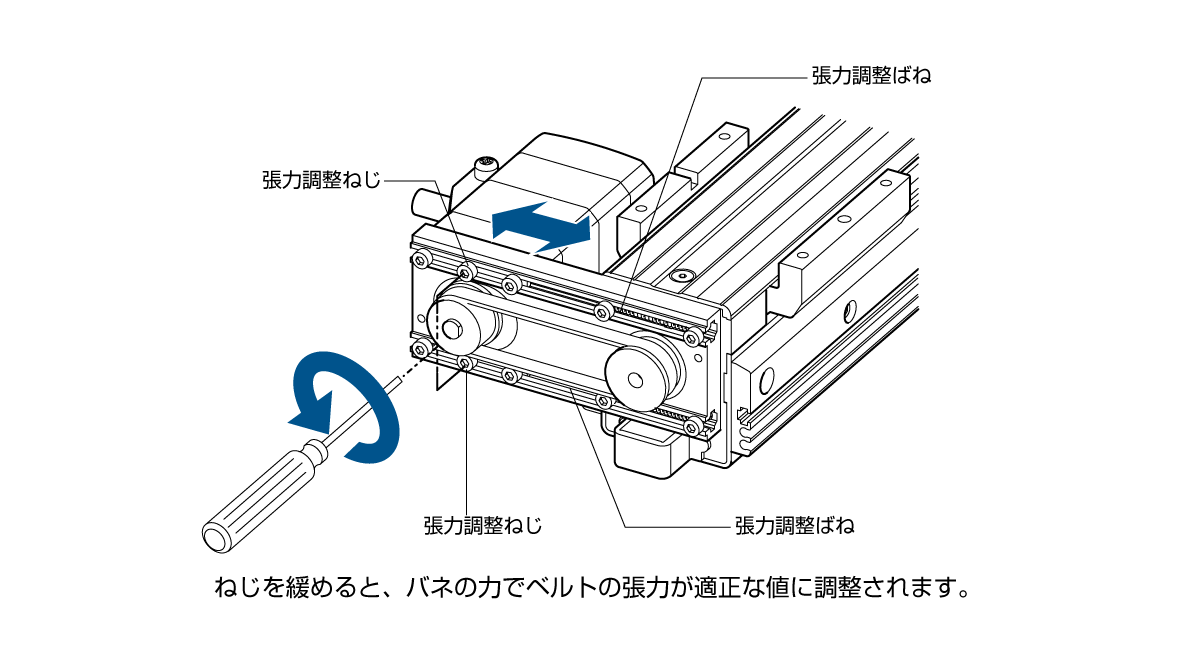

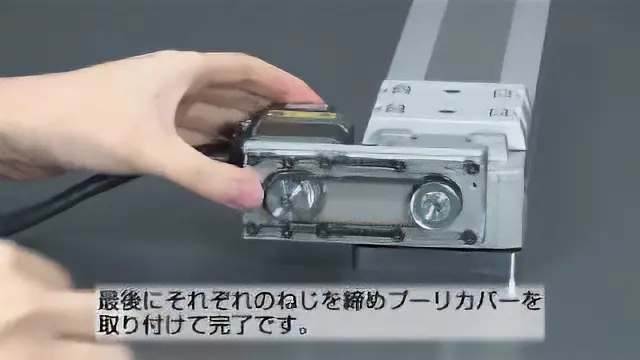

Easy belt replacement (fold-over type)

Our unique belt tension adjustment mechanism (patented) makes belt replacement easy.

Directly attach the load (with shaft guide/shaft guide cover)

With shaft guide/with shaft guide cover

This ensures stable velocity with minimal speed variation, even at low speeds (1.25 mm/s). Both straight and folded options are available.

Advantages of the AZ series

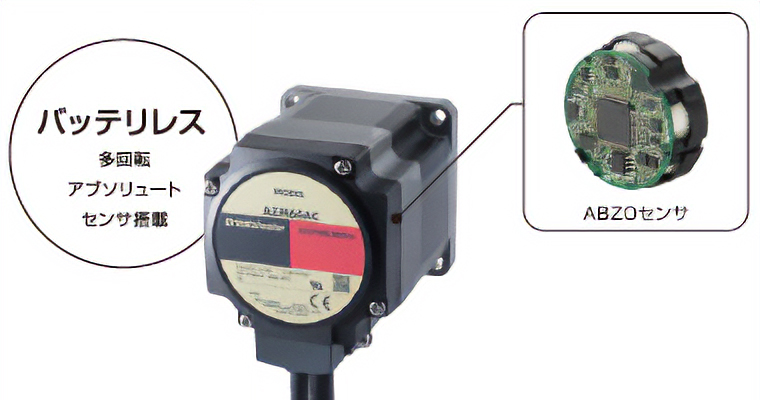

Equipped with a battery-less absolute sensor

Equipped with a small, battery-less mechanical absolute sensor (ABZO sensor), it contributes to improving productivity and reducing costs.

Mechanical sensors retain position information even when power is off

Multi-rotation absolute sensor: Detects the absolute position within a range of ±900 rotations (totaling 1800 rotations) of the motor shaft from the reference origin.

No external sensor required

Since it is an absolute system, origin and limit sensors are not required.

merit

- High speed return to origin + Improved return to origin accuracy

- Cost reduction

- Reduced wiring

- Not affected by external sensor malfunctions

Battery-less

Mechanical sensors do not require batteries.

Position information is managed mechanically by the ABZO sensor.

merit

- No need to replace batteries

- Free driver installation

- Reliable overseas shipping

Sequence function simplifies main programs

The AZ series is equipped with a wide range of sequence functions, such as linked operation, timer settings between operations, conditional branching, loop operation, etc. (Excluding some models) These can be set using the support software MEXE02, simplifying the sequence program of the upper system.

- Positioning operation data setting value (maximum 256 points)

- General-purpose input/output points (10 inputs, 6 outputs)

- Number of communication inputs/outputs (16 inputs, 16 outputs)

Functions that help collect data on motor operation status and perform preventive and predictive maintenance

It is equipped with a wide range of monitor functions for checking the operating status of the motor, etc.

By using the appropriate functions according to the situation, it can be useful for shortening the start-up and adjustment time of the device, as well as for maintenance and preservation.

Monitor function that visualizes the motor operation status and is useful for data collection

The ABZO sensor installed in the AZ series allows you to monitor the motor’s operating status numerically.

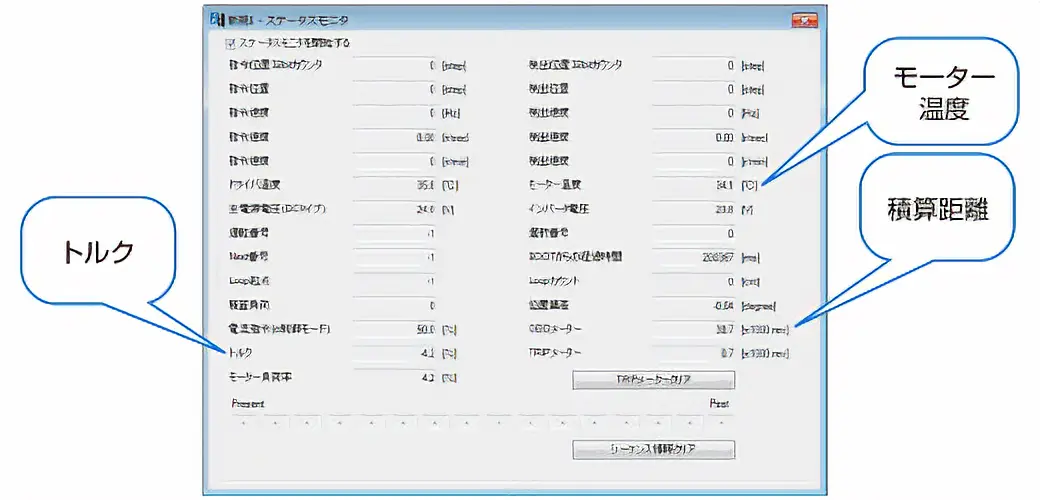

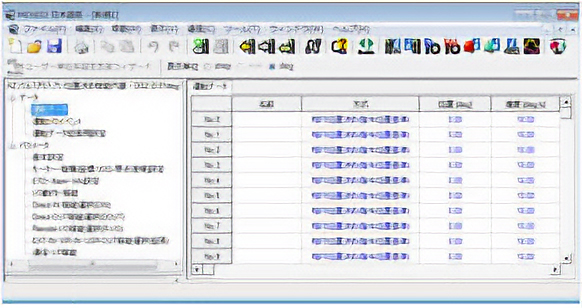

[Monitoring using the support software MEXE02]

In addition, the type with built-in positioning function can collect data at a higher level master via an FA network.

Information functions useful for preventive and predictive maintenance

By setting a desired value for each information monitor item, a signal can be output to an external device when that value is reached.

By importing this information into a higher-level device, it can be used to detect problems early and adjust the maintenance schedule for the product.

Information function example

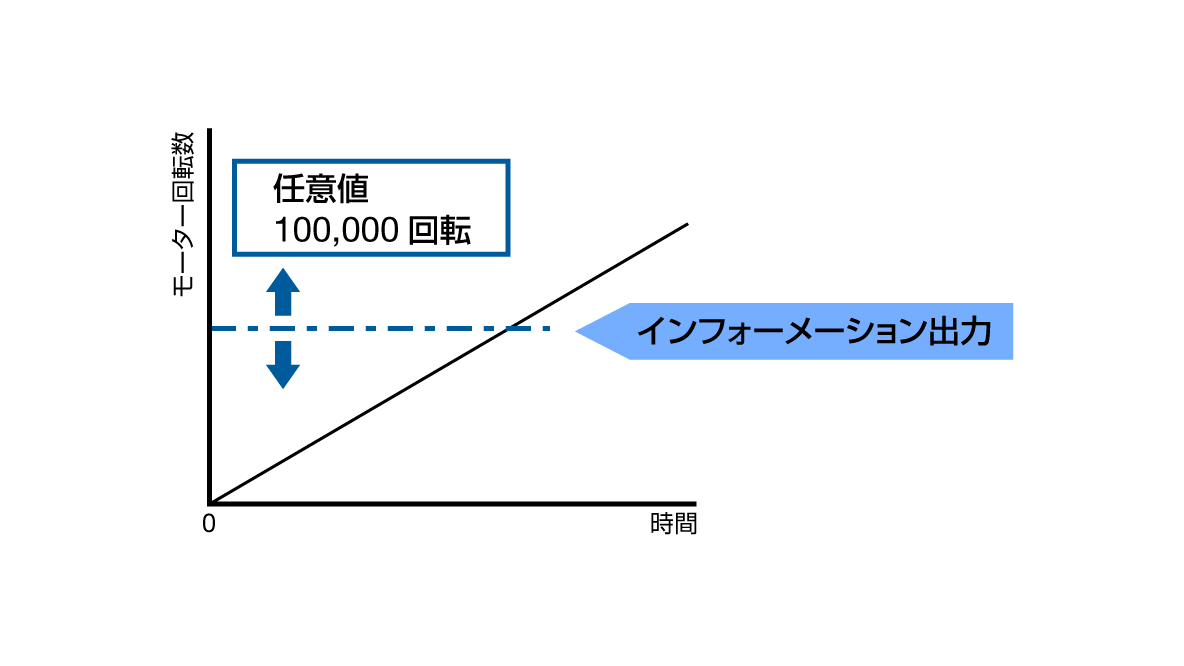

TRIP Information

The desired output speed is set in advance, and the output will occur when that speed is reached (the motor will continue to operate).

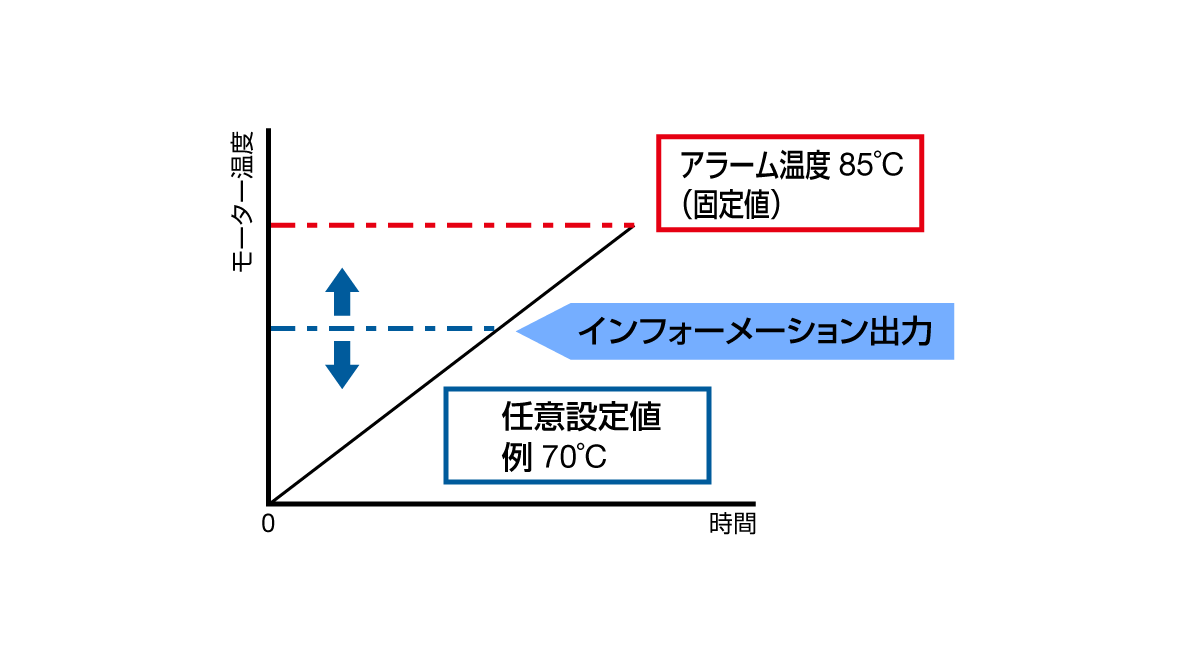

Temperature Information

The desired output temperature is set in advance, and the output will start when the temperature is reached (the motor will continue to operate).

Unified wiring, control and maintenance parts

We offer a variety of mechanical products equipped with the αSTEP AZ series.

As they are equipped with the same motor and driver, wiring, control, and maintenance parts can be unified.

Unification of wiring

The wiring for the motor cable, input/output signals, power supply, etc. is the same.

Unified controllability

The control method is the same, so it can be used in the same way. In the case of network control, the remote I/O and command codes are the same. This saves the effort of creating programs.

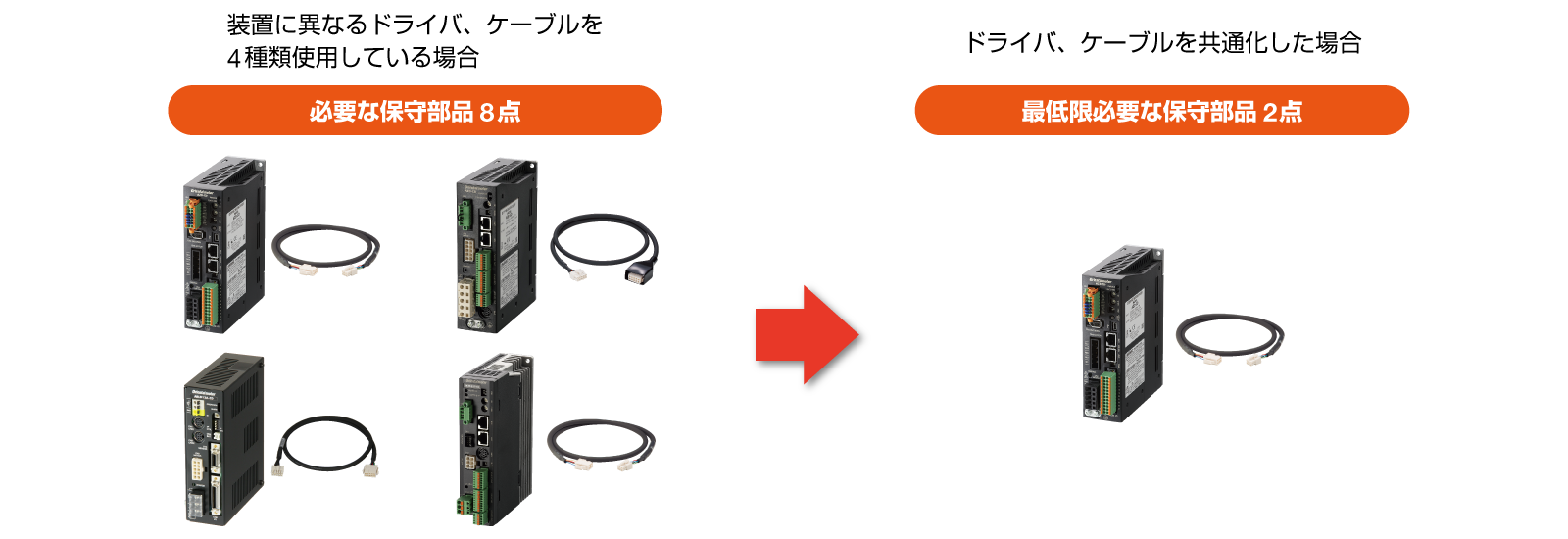

Standardization of maintenance parts

The number of maintenance parts can be kept to a minimum because the motor, driver, and cable are common, which is expected to reduce management costs (parts costs, management space).

Lineup featuring the AZ series

Electric actuator (AZ series installed)

| Motorized Slider | Electric Cylinder | Compact Electric Cylinder | Rack and pinion system | Electric Gripper | Hollow Rotary Actuator |

|---|---|---|---|---|---|

| EAS series EZS series EZSH series | EAC Series | DR series DRS2 series | L-Series | EH Series | DGⅡ series |

- The power input of the installed motor differs depending on the series. Please check the page for each series for detailed lineup.

Driver characteristics and types

Drivers can be selected according to the host system

We offer a lineup that can support a variety of controls, systems, and interfaces.

| Driver Type | Supported Interfaces | Single Axis Driver | ||

|---|---|---|---|---|

| AC power in | DC power in | |||

|  | |||

| Network compatibility | Direct control of the driver from a higher-level control device | EtherCAT | ○ | ○ |

| EtherNet/IP™ | ○ | ○ | ||

| PROFINET | ○ | ○ | ||

| MECHATROLINK-Ⅲ | ○ | – | ||

| SSCNETⅢ/H | ○ | – | ||

| Built-in positioning function | Operation data is stored in the driver. Control is possible with Modbus (RTU) and I/O . CC-Link control is possible by using a network converter. | Modbus(RTU) I/O CC-Link * | ○ | ○ |

| Pulse train input with RS-485 communication | Controlled by pulse signals. Motor status information can be monitored via Modbus (RTU). | Pulse train Modbus (RTU) | ○ | ○ |

| Pulse train input | Pulse signal control | Pulse train | ○ | ○ |

- EtherCAT® is a patented technology licensed from Beckhoff Automation GmbH (Germany) and is a registered trademark.

- EtherNet/IP™ is a trademark of ODVA.

- PROFINET is a trademark or registered trademark of PROFIBUS Nutzerorganisation eV (PNO).

- MECHATROLINK is a registered trademark of the MECHATROLINK Association.

- SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

- CC-Link is a registered trademark of the CC-Link Partner Association.

Support software, monitor function

Easily control from a PC using the support software MEXE02

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as perform teaching and monitor various statuses.

A variety of functions provide comprehensive support from start-up to maintenance

We provide functions that are useful for wiring checks and test runs.

- Setting and saving operation data

- I/O Monitor

- Teaching/Remote Operation

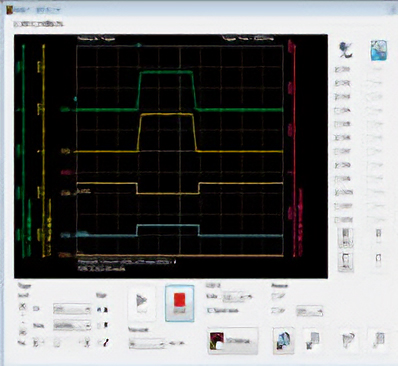

We provide functions that are useful for adjusting motor operation after the equipment is installed.

- Waveform Monitor

We provide functions that are useful for diagnosing problems and for maintenance after operations have started.

- Alarm Monitor

- Unit Information Monitor

- Status Monitor

Related product

AZ Series Multi-Axis Driver DC Power Input

It can connect our AZ series DC power input motors and the electric actuators that are equipped with them.

- EtherCAT® is a patented technology licensed from Beckhoff Automation GmbH (Germany) and is a registered trademark.

- MECHATROLINK is a registered trademark of the MECHATROLINK Association.

- SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

AZ series mini driver DC power input

This mini driver is designed to be even smaller and lighter than box type drivers. It also supports battery power, allowing you to use it for a wider range of purposes than ever before.

Related Products

-

TERAOKA SEISAKUSHO 791 Aluminum Foil Double-coated Conductive Adhesive Tape

-

SHOWA SOKKI 2507 AC output vibration sensor for PLC

-

SHIGEMATSU GM77S Gas Respirator

-

Kitz UEL,UELM Stainless & High Alloy Class 150 Gate Valve

-

Hammer Caster 320ER Stainless Steel Caster

-

Nippon Seimitsu FC-125-D Industrial Vacuum Cleaners