- Home

- Products

- Ross Asia 27 Series Pilot Operated Check Valve Safety cat. 1 PL c, in-line mounting, with and without pressure relief

Japan, Ross Asia

Ross Asia 27 Series Pilot Operated Check Valve Safety cat. 1 PL c, in-line mounting, with and without pressure relief

Made in Japan

Manufacturer : Ross Asia

Model : 27 Series Pilot Operated Check Valve

Pilot Operated Check Valves 27 Series Product Overview

Features

PRODUCT CREDENTIALS

PRODUCT CREDENTIALS

Specifications

Applications

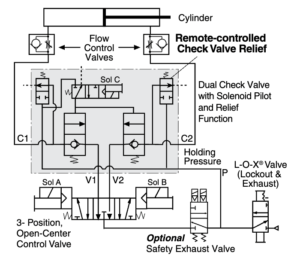

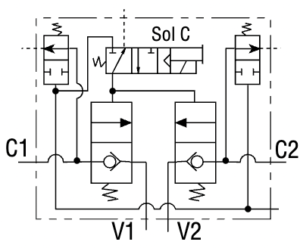

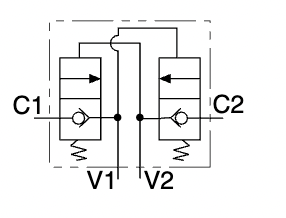

| Solenoid Pilot Controlled Valve Application | |

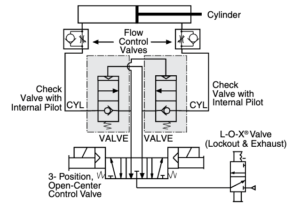

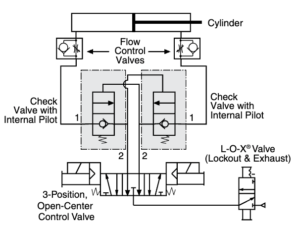

| Dual Pilot Operated Check Valve | Circuit Features

|

|

|

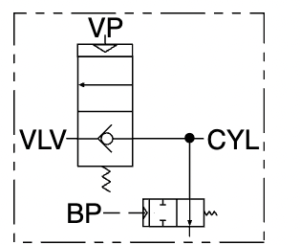

| Pressure Controlled Valve Application | |

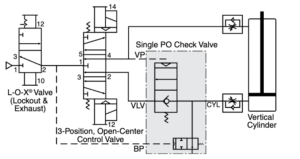

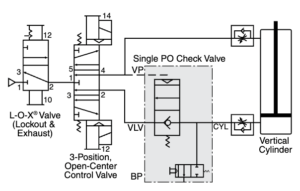

| Single Pilot Operated Check Valve | Circuit Features

|

|

|

| Single Pilot Operated Check Valve | Circuit Features

|

|

|

| Single Pilot Operated Check Valve with Trapped Pressure Relief Application | Circuit Features

|

|

|

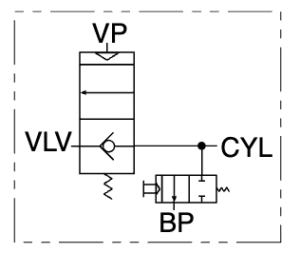

| Pressure Controlled Valve Application | |

| Single Pilot Operated Check Valve with Manual Trapped Pressure Relief | Circuit Features

|

|

|

| Single Pilot Operated Check Valve | Circuit Features

|

|

|

| Single Pilot Operated Check Valve | Circuit Features

|

|

|

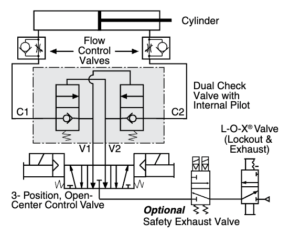

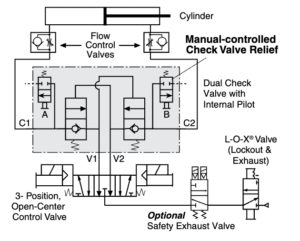

| Dual Pilot Operated Check Valve Manual Trapped Pressure Relief | Circuit Features

|

|

|

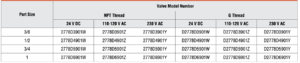

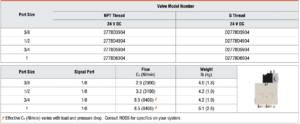

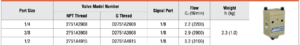

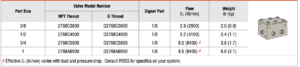

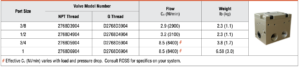

Ordering Information – Solenoid Pilot Controlled Valves

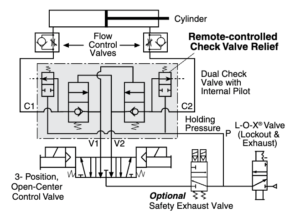

Dual Pilot Operated Check – Valves with Remote Trapped Pressure Relief

Valves with DIN EN Connector(2-Way 2-Position Valves)

Valves with 3-Pin Mini Connector(2-Way 2-Position Valves)

Valves with 4-Pin Micro Connector(2-Way 2-Position Valves)

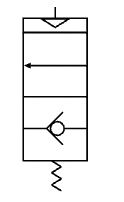

| Valve Schematic | |

|

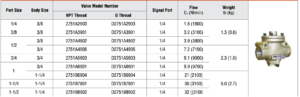

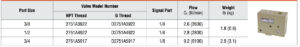

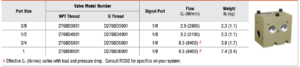

Ordering Information – Pressure Controlled Valves

Single Pilot Operated Check – Valves without Trapped Pressure Relief

Valves without Trapped Pressure Relief – GEN I( 2-Way 2-Position Valves)

Valves without Trapped Pressure Relief – GEN II(2-Way 2-Position Valves)

Valves with Remote Trapped Pressure Relief(2-Way 2-Position Valves)

Valves with Manual Trapped Pressure Relief(2-Way 2-Position Valves)

| Valve Schematic | ||

| Trapped Pressure Relief Options | ||

| None | Remote | Manual |

|

|

|

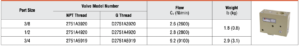

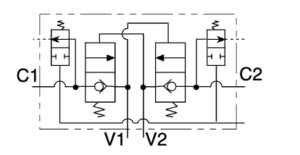

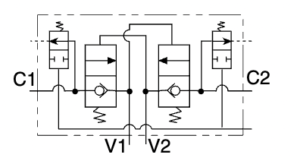

Dual Pilot Operated Check – Pressure Controlled Valves

Valves without Trapped Pressure Relief(2-Way 2-Position Valves)

Valves with Remote Trapped Pressure Relief(2-Way 2-Position Valves)

Valves with Manual Trapped Pressure Relief(2-Way 2-Position Valves)

| Valve Schematic | ||

| Trapped Pressure Relief Options | ||

| None | Remote | Manual |

|

|

|

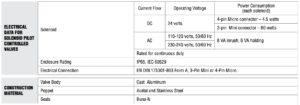

Valve Technical Data

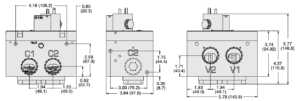

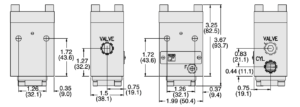

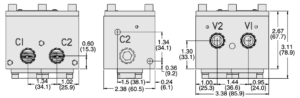

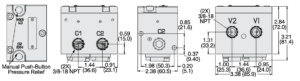

Solenoid Pilot Controlled Valves – Dual PO Check with Remote Trapped Pressure Relief

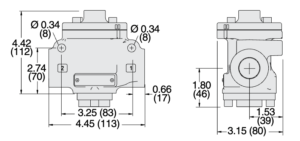

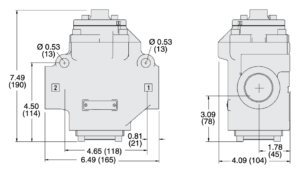

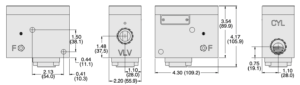

| Dimensions-Inches(mm) | |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

| Port Size 3/4 |  |

| Port Size 1 |  |

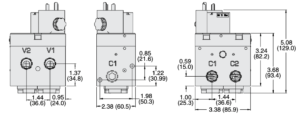

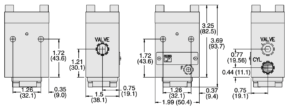

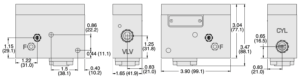

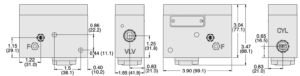

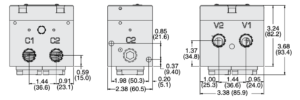

Pressure Controlled Valves – Single PO Check Valves without Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Port Size 1/4 |  |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

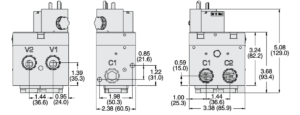

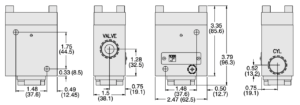

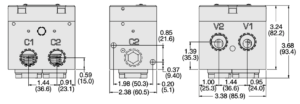

Pressure Controlled Valves – Single PO Check Headline Valves without Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Body Size 3/8 |  |

| Port Size 3/4 |  |

| Port Size 1-1/4 |  |

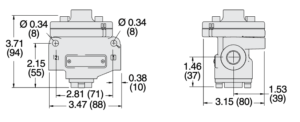

Pressure Controlled Valves – Single PO Check Valves with Remote Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

| Port Size 3/4 |  |

Pressure Controlled Valves – Single PO Check Valves with Manual Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

| Port Size 3/4 |  |

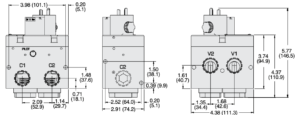

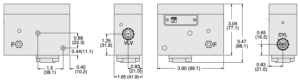

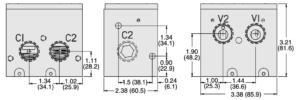

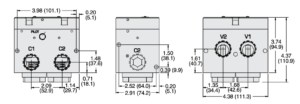

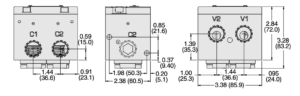

Pressure Controlled Valves – Dual PO Check without Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

| Port Size 3/4 |  |

| Port Size 1 |  |

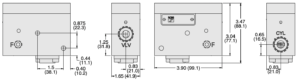

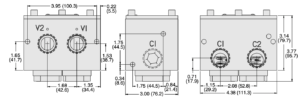

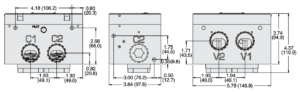

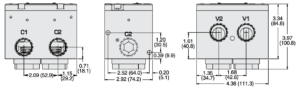

Pressure Controlled Valves –Dual PO Check with Remote Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

| Port Size 3/4 |  |

| Port Size 1 |  |

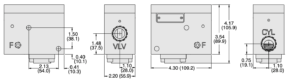

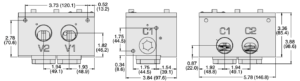

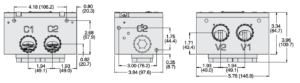

Pressure Controlled Valves – Dual PO Check with Manual Trapped Pressure Relief

| Dimensions-Inches(mm) | |

| Port Size 3/8 |  |

| Port Size 1/2 |  |

| Port Size 3/4 |  |

| Port Size 1 |  |

Accessories

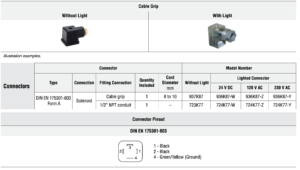

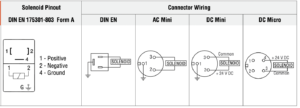

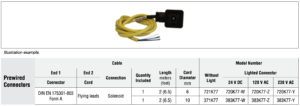

PREWIRED ELECTRICAL CONNECTORS

ELECTRICAL CONNECTORS