Japan, Ross Asia

Ross Asia Electro guard Energy Separation Systems – Electric, Pneumatic, Hydraulic

Made in Japan

Manufacturer : Ross Asia

Model : Electro guard

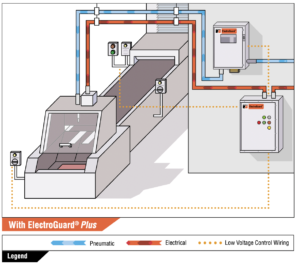

ElectroGuard ® Plus Energy Isolation System for Single- or Multi-Zone Machines

Standardize on a New Level for Machine Energy Isolation ElectroGuard ® Plus

The ROSS ElectroGuard ® Plus , provides a new level of machine operator safety and can contribute to enhanced productivity. The flexibility and capabilities make it ideal in virtually any application where operators work within the machine. This system integrates world-class products to offer a system you can trust and the highest level of safety available.

The ElectroGuard ® Plus system has the ability to isolate electrical, pneumatic, and hydraulic energy for a whole machine or by zone in a multi-zone machine system.

The ElectroGuard ® Plus system takes signals from the individual Remote Lockout Stations (RLS) and performs the entire energy isolation procedure, including verification, after which a lock is applied by the operator or maintenance worker. This simple procedure eliminates the downtime that is normally wasted on traveling to and from the isolation devices and locking out every energy source on the machine (or in the zone). Of course, this time savings is realized when res tarting as well – all of which makes for a rapid return on investment. Furthermore, the ability to control multiple zones separately provides the added benefit of not always having to shut down the entire machine which can also contribute to the rapid return on investment.

ElectroGuard ® Plus – A System Approach to Machine Energy Isolation

The ElectroGuard ® Plus system sets a new standard for hazardous energy isolation by greatly easing the task of the machine operator or maintenance personnel to properly perform Lockout/Tagout procedures consistently. Which, in turn, can offer greater assurance of compliance along with the added value of improved productivity.

ElectroGuard ® Plus systems use a modular approach for maximum scalability and flexibility. ElectroGuard ® Plus systems include low- voltage remote lockout stations and modular control panels, factory-sealed and certified to Category 4/PL e (pending), with options for pneumatic and hydraulic isolation to provide the complete solution in a flexible, scalable, maintainable, and cost effective system.

ElectroGuard ® Plus provides many features to benefit your business:

- Helps reduce workplace injuries resulting from complicated Lockout/Tagout procedures

- A cost-effective solution to conform with OSHA requirements for control of hazardous energy

- Simplifies operator Lockout/Tagout procedures to help improve productivity

- Modular, pre-wired for quick installation

- Improves Safety by eliminating errors and omission of steps during complex lockout/tagout procedures

- Higher cycle life than mechanical disconnects, for reduced downtime

With ElectroGuard ® Plus you benefit from:

- Fewer lost time accidents

- Improved productivity

- A standard procedure throughout your facility

- Greater plant operation accuracy due to downtime communication

- Ease of specifying, purchasing, setup and maintenance

ElectroGuard ® Plus is ideal for applications where machines have:

- Multiple access locations requiring operator travel time to the disconnecting devices

- Frequent interruptions due to jams, lubrication, etc., causing loss of productivity during the time of proper isolation

- Multiple sources of energy requiring a complex Lockout/ Tagout procedure

- Maintenance personnel operating electrical disconnects within the hazardous zone

| Safety Features | BENEFITS |

System approach to simplify hazardous energy isolation procedures | When the energy sources are controlled by the ElectroGuard ® Plus system, it enhances safety by eliminating the need for locking multiple locations, helping reduce the chances of an energy source being overlooked |

| Remote Lockout Stations (RLS) | The operator switches a low power device, without the flash hazard associated with typical electrical disconnect switches. |

| “System Isolated” light on RLS | he “System Isolated” light is a positive indication of the ElectroGuard ® Plus sources’ zero energy state, notifying the operator it is safe to enter the machine. |

Certified to ISO 13849-1 Category 4, PL e (pending) | Highest functional safety performance possible to help improve workplace safety |

Redundant, independent, self monitoring, functional design | ElectroGuard ® Plus faults are detected in time to prevent loss of the safety function |

| Grounding contactor | Safety features to guard against capacitive coupling, inertial regeneration or other sources that may cause residual voltage |

| Ground loss monitor | Additional safety features to detect the loss of system ground |

| Electrical interlock devices on isolation contactors | Multiple technologies used for fault protection |

| Factory-sealed panels | Tamper evident seals for system integrity |

ROSS CONTROLS ® energy isolation valves DM 2 Pneumatic HBB Hydraulic | Maintain system integrity with control-reliable pneumatic and hydraulic valve isolation systems |

Conformity to UL standards (reference page 3 for complete industry standards list | Pre-engineered conformity to meet industry standards |

| Productivity Features | BENEFITS |

| Single Point Lockout/Tagout | Isolate electrical, pneumatic, and hydraulic energy in a single action, reducing the time to put the machine into a safe mode |

| Low-voltage Remote Lockout Station | Easy to operate device |

| Multiple Remote Lockout Stations (RLS) | Allows placement of lockout device near every access point |

| Standardized System | Similar lockout/tagout procedure between machines, throughout the facility |

| Status Communication | Use to measure # cycles, cycle time, location of lockout/tagout occurrences |

| Multi-Zone Control | Increase productivity by only locking out the appropriate zone where access is needed instead of the whole machine |

| Maintenance Features | BENEFITS |

| Electrical isolation using power contactors | Dramatically increased cycle life compared with mechanical disconnects |

| Modular design | Ease of trouble-shooting to the panel/module level |

| Removable, factory sealed panels | Quick replacement of failed panels |

| System approach | Common look and feel to each system in the facility |

Safety PLC-based system with HMI for advanced troubleshooting | Ease of troubleshooting |

| Installation Features | BENEFITS |

| Low voltage Remote Lockout Stations | Low install cost |

| Compact size Remote Lockout Station | Easy to locate on machine |

| Expandable | Simple to add more options after installation |

Here’s an example of a typical machine having energy isolation devices located on a wall, close to the machine, and a single start/stop station.

When a process jam occurs the operator must travel around between the start/stop station and the energy isolation devices (LOTO) and the jam to get production running again. The clearing of the jam is only a small portion of the production down time; the remaining time is spent on the proper LOTO procedure. Operator travel time and manually locking of two isolation devices is a large portion of the total recovery time.

Time: 70 seconds.

The ElectroGuard ® Plus system is installed in place of the manual isolation devices, while multiple Remote Lockout Stations are installed near the machine access locations. With this simplified LOTO procedure and close proximity of the Remote Lockout Stations, the clearing of a jam is now the largest percentage of the downtime.

Time: 35 seconds

Flexibility in Packaging

The ElectroGuard ® Plus and optional panels are available with standard enclosure ratings of NEMA type 1, 4, and 12. In addition, the system configuration is available in the following styles, to meet your requirements.

- Standard ElectroGuard ® Plus configuration as a wall mounted or floor standing panel

- Motor Control Center style enclosure, available with power bus structure

Ease of Maintenance

The ElectroGuard ® Plus modular design allows for trouble-shooting to a factory sealed panel, and replacement of the failed panel. Flexibility for “Behind the Seal” maintenance includes the following:

- Return to repair services

- Purchase on-site start-up services from ROSS CONTROLS ®

ElectroGuard ® Plus – Unsurpassed Advantages

The main goal of the ElectroGuard ® Plus Energy Isolation System is to optimize Lockout & Tagout procedures in order to enhance safety and productivity.

All ElectroGuard ® Plus systems utilize an AB Compact Guardlogix 5380 Safety PLC with 5069 Safety IO and certified SafetyInstructions that are used in ROSS Controls’ Add-On Instructions (AOI’s). The AOI’s are locked and uneditable by users of the ElectroGuard ® Plus system.

Provides simple, and quickly accessible lockout devices wherever needed, reducing the tendency of machine operators to take an unsafe shortcut

When the energy sources are controlled by the ElectroGuard ® Plus system, it provides a single point lockout for multiple sources of energy, helping reduce the chances of an energy source being overlooked

Third party certified conformity to the highest safety category – when ElectroGuard ® Plus faults occur the safety function is always performed (pending certification)

Modular for quick and easy maintenance

Factory sealed panels for system integrity

Establish uniform energy isolation process for all stations & all sites

HMI module for advanced, rapid troubleshooting ElectroGuard ® Plus –

Single-zone ElectroGuard ® PlusSystem Overview

Single-zone ElectroGuard ® Plus systems can isolate up to six energy sources (any combination of electrical, pneumatic, & hydraulic), and can utilize as many as thirteen remote lockout stations (RLS).\

Potential capacity could be:

- 1 zone

- Up to 6 RLS Stations or up to 13 with external RLS Interface Panel (RIP)

- Controls up to 6 Energy Sources (combination of EIP, PIP, & HIP

Single-zone ElectroGuard ® Plus Systems include:

Multi-Zone ElectroGuard ® Plus System Overview

(8 Zones, 69 Remote Lockout Stations, and 32 Energy Sources)

The ElectroGuard ® Plus main Control Panel can be extended to include an 8 port or 16 port Ethernet Switch to expand system capacity.

Potential capacity could be:

- 8 zones (Base + 7 remote)

- 69 RLS Stations (Base + 7 RIP)

- 32 Energy Sources (Base + 8 OCP)

Multi-zone ElectroGuard ® Plus Systems include Base System Capabilities and the following:

Branch Circuit Protection

Application Rated

- None – incoming line lugs only

- Fusible disconnect

- Circuit Breaker

Remote Lockout Station

- Provision for top or bottom conduit entry

- Rotary lockable disconnect or trapped key options

- White or green isolation status indicator light

- Multiple enclosure materials/ IP ratings available

Selectable Time Delay

Provision to incorporate a machine cycle stop with the actuation of the Remote Lockout Station

- Adjustable 1 to 30 seconds

Pneumatic Isolation Module

- Isolates the pneumatic energy

- 30 to 120 psig (2 to 8 bar)

- 3/4″ or 1″ valve port

Cover Mounted Metering

- Single- or three-phase voltmeter

- Single- or three-phase ammeter

Hydraulic Isolation Module

- Isolates the hydraulic energy

- Up to 5000 psig (344 bar)

- 1″ valve port

Safety Interface Signals

Provision to incorporate a machine cycle stop with the actuation of the Remote Lockout Station

- Two machine status inputs

- Two ElectroGuard ® Plus status outputs

Operation

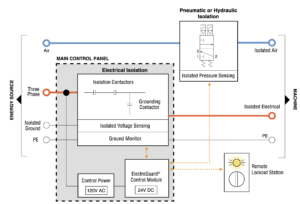

The ElectroGuard ® Plus system is installed between the energy sources and the machine.

The Control Module controls and verifies the ElectroGuard ® Plus system functions. Every function is commanded and monitored for proper completion, and is comprised of the safety PLC, electromechanical devices, and safety control relays. The Control Module sends and receives signals from the Electrical, Pneumatic, Hydraulic, and Motor Isolation modules and panels as well as the Remote Lockout Stations.

If the ElectroGuard ® Plus Main Control Panel ground is broken, or a fault occurs within the isolation system, the

ElectroGuard ® Plus system will isolate all energy sources. Under a fault or shutdown condition of the ElectroGuard ® Plussystem, the “system isolated” light will not be illuminated. No light means no entry.

The ElectroGuard ® Plus system is powered by a 120V AC control transformer in the Main Control Panel and 24V DC power supply within the Control Module.

Sequence of Isolation Operation

1. The operator initiates the isolation sequence by turning the handle on the Remote Lockout Station from the ON to OFF position.

2. The control module responds by commanding all isolation modules & panels – electrical, pneumatic, and hydraulic – to isolate and verify isolation.

- The Electrical Isolation Module opens the series contactors, the voltage sense circuit monitors the isolated voltage, and, when safe, the grounding contactor connects the isolated electrical lines to the isolated ground. Electrical isolation is completed and verified by the Control Module.

- The Motor Isolation Module opens the contactor (in series with a VFD with Safe Torque Off functionality), the voltage sense circuit monitors the isolated voltage, and, when safe, the grounding contactor connects the isolated electrical lines to the isolated ground. Electrical isolation is completed and verified by the Control Module.

- The Pneumatic and Hydraulic Isolation Panels switch off the pneumatic and hydraulic valves, and redundant pressure sensors verify isolation has been completed. Pneumatic and hydraulic isolation is completed and verified by the Pneumatic and Hydraulic Control Panels.

3. After successful isolation, the Control Module illuminates the operator’s Remote Lockout Station “system isolated” light.

4. The operator then applies a LOTO lock to the Remote Lockout Station handle, and it is safe to work on the machine.

| Voltage Range | 208 to 600V AC, 50/60 Hz |

| Rated Electrical Isolation | Current Range – 43 to 1250 A |

| Rated Pneumatic Isolation | Pressure Range – 30 to 120 psig (2 to 8 bar) |

| Rated Hydraulic Isolation | Pressure Range – 500 to 5000 psig (35 to 344 bar) |

| Remote Lockout Station | Low Voltage 24V DC, supplied from ElectroGuard® Plus Main Control Panel |

| Expansion Module | Low Voltage 24V DC, supplied from ElectroGuard ® Plus Main Control Panel |

| Enclosure Ratings | NEMA Type 1, 4, or 12 |

| Enclosure Styles | Wall-mount or Free-standing MCC-style Enclosure |

Conformity to Industry Standards

- UL508A with cULus listing (pending)

- Certified to ISO 13849-1 Category 4, PL e (pending)

- Designed to conform to OSHA for control of hazardous energy

Related Products

-

Kitz AKTAFM Floating Type 600 Brass Ball Valves (Full Bore)

-

Nippon Chemical Screw PEI/PBO 19.5-24-36L PEI/Ω (omega type)

-

Kanetec LM-R Rectifier Built-In Large Electromagnetic Lifma

-

Wasino Kiki Various Options for Sight Glass

-

Chiyoda Seiki GM-1000 Small/Medium/Large flow/Pressure regulator/Governor For General Industrial Gas (primary pressure: 0.1 to 1.56 MPa/set pressure 0.02 to 0.3 MPa)

-

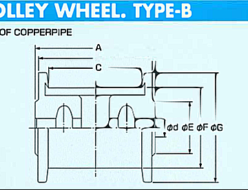

Asahi Bagnall Type B Trolley Wheel