Japan, Ross Asia

Ross Asia SERPAR® 35 Series Double valve with electronic DS monitor

Made in Japan

Manufacturer : Ross Asia

Model : SERPAR® 35 Series

SERPAR ® Double Valves with D-S Monitor 35 Series Product Overview

Clutch/Brake Control Function

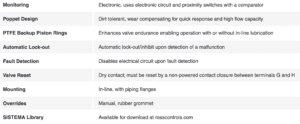

The SERPAR ® double valve is designed to provide control of clutch/brake mechanisms on stamping presses, and many other critical applications such as alternative lockout systems for energy isolation, as well as other Category -3 and -4 safety circuits.

The SERPAR ® Series valves are internally monitored double valves with a built-in monitoring device that checks for the proper operation of each valve element. If the internal monitor detects a valve fault on a particular cycle, the double valve will fail to a safe condition (all downstream air is exhausted) and the monitor will lock-out to inhibit further operation of the device. Normal operation can only be resumed by properly resetting the monitor.

VALVE FEATURES

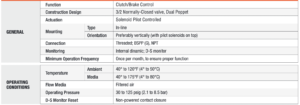

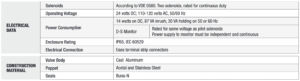

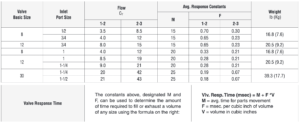

Specifications

PRODUCT CREDENTIALS

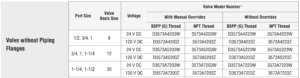

Ordering Information

MODEL NUMBER CONFIGURATOR(3-Way 2-Position Valves)

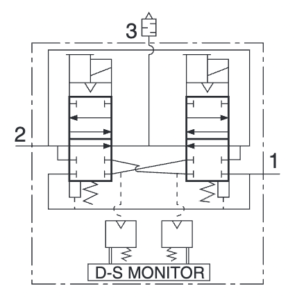

| Valve Schematic |

|

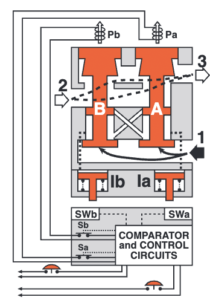

Valve Operation

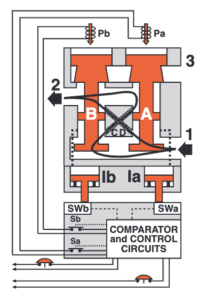

| Conditions at Star | Inlet 1 is closed to outlet 2 by both valve elements A and B. Outlet 2 is open to exhaust 3. Contacts of switch SW are closed. Monitoring pressure signals at both ends of spool S are exhausted. |

| |

| Normal Operation | Simultaneously energizing both solenoids actuates both pilots and causes valve elements A and B to shift. Inlet 1 is then connected to outlet 2 via crossflow passages C and D. Exhaust 3 is closed. Monitoring pressure signals go to pressure indicators Ia and Ib, causing the indicator pins to be extended and to actuate proximity switches SWa and SWb. In normal operation, each pair – solenoids, valve elements, indicators, and proximity switches – responds in unison so that the comparator circuits “read” the operation as normal. |

| |

Completion of Normal Cycle | Simultaneously de-energizing both solenoids returns the valve to the “Conditions at Start” described above |

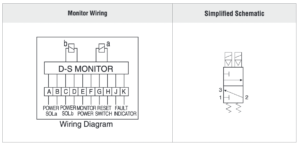

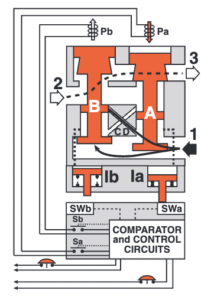

Detecting a Malfunction | A malfunction in the system or the valve itself could cause one valve element to be open and the other closed. Air then flows past the inlet poppet on valve element A, into crossflow passage D, but is substantially blocked by the spool portion of element B. The large size of the open exhaust passage past element B keeps the pressure at the outlet port below two percent of inlet pressure. Full monitoring air pressure from side A goes to pressure indicator Ia so that its pin is extended and actuates proximity switch SWa. When the time interval between the signal to a solenoid and the signal from its corresponding proximity switch exceeds approximately 175 milliseconds, the D-S monitor breaks contacts Sa and Sb as soon as solenoid power is removed. This allows valve element A to return to the closed position. |

| |

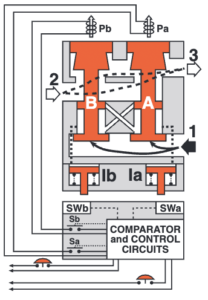

| D-S Monitor Locked-out | With the valve locked out by contacts Sa and Sb, solenoids Pa and Pb cannot be energized. The monitor must be reset before another valve cycle can begin. Reset can be achieved by a separately connected ancillary switch, but not if the pilot solenoids are energized. The monitor can be reset by removing and reapplying power to the monitor even when the pilot solenoids are energized. For this reason it is necessary to have the pilot solenoids de-energized during and following reset to prevent inadvertent and possibly dangerous cycling of the press. |

|

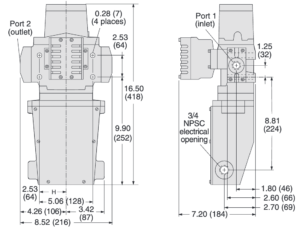

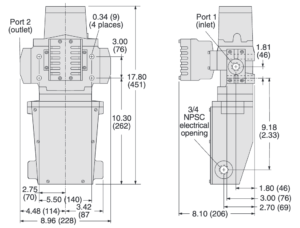

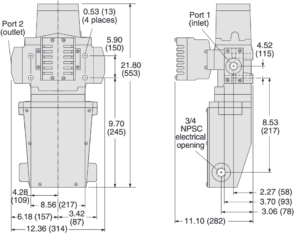

| Dimensions-Inches(mm) | |

| Basic Size 8 |  |

| Basic Size 12 |  |

| Basic Size 30 |  |

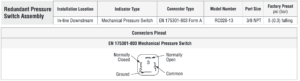

Accessories & Options

ENERGY RELEASE VERIFICATION

REPLACEMENT VALVES

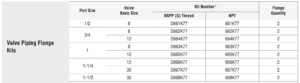

CONNECTION PIPING KITS

Related Products

-

Watanabe RTB [RTD] Duct/Piping insertion type with terminal box

-

SAKUSAKU SEEN1203ST SPP200 Milling Insert Square 15°Positive

-

NAC – AL TYPE 20 Steel (Chrome-plated) PM (Male thread)

-

OSC55CB006 Corrosion Test Chamber

-

Gentos XB-B05R Multifunctional Bike Light (160lm / 1350cd)

-

Hammer Caster 405K Decorative Chromate Coated Caster