Japan, Showa Measuring Instruments

Showa Measuring Instruments Strain Gages Accessories

Made in Japan

Manufacturer: SHOWA MEASURING INSTRUMENTS Co., Ltd.

Features

In our modern society, machines and structures are essential for safe, smooth living, requiring confirmed functionality and safety. Strain gages are key sensors that detect and measure strain and stress, ensuring these facilities remain safe.Strain gages, fundamental sensors for detecting and measuring strain and stress, play a key role in ensuring the safety of these facilities.

The history of strain gages dates back to 1938 when Simmons & Ruge first designed bonded type strain gages in America. In 1962, SHOWA Company began manufacturing foil grid type strain gages in Japan, marking the first of its kind. These devices are essential for assessing the strength and properties of materials like metals, rubber, plastics, and ceramics used daily.

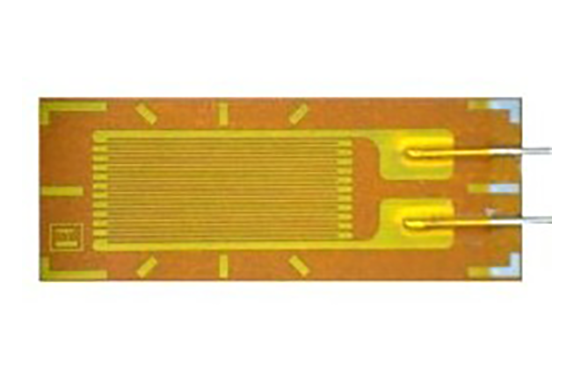

Terminals

The terminals are placed between strain gage lead and the heavier leads required for the run to measuring or recording instruments to protect strain gage leads from disconnecions or inferior insulation which are lilely to take place during strain gage installation and measurement.

| Appearances | Type | Dimensions(mm) | Number of pieces per Packet | Remarks |

|---|---|---|---|---|

| FG-5T | 6×20×0.15 | 10 | |

SFG-5T | 6×20×1.0 | 10 | Self-Adhesive Type | |

| FG-7T | 7×26×0.15 | 10 | |

SFG-7T | 7×26×1.0 | 10 | Self-Adhesive Type | |

| FG-10T | 12×40×0.15 | 10 | |

SFG-10T | 12×40×1.0 | 10 | Self-Adhesive Type | |

| FG-15T | 16×56×0.15 | 10 | |

SFG-15T | 16×56×1.0 | 10 | Self-Adhesive Type | |

| FGR-10T | 10×25×0.15 | 10 | For 2 or 3 Elements Gages |

SFGR-10T | 10×25×1.0 | 10 | Ditto,but Self-Adhesive Type | |

| FGR-15T | 15×38×0.15 | 10 | For 2 or 3 Elements Gages |

SFGR-15T | 15×38×1.0 | 10 | Ditto,but Self-Adhesive Type | |

| FGF-5T | 15×40×0.15 | 10 | For 5 Elements Gages |

SFGF-5T | 15×40×1.0 | 10 | Ditto,but Self-Adhesive Type |

Adhesive

Select an adhesive that is compatible with the measurement conditions.

| Type | Use | Bonded Material | Operating Temperature Range | Adhesion Method | Applied Pressure (kPa) | Capacity (g) |

|---|---|---|---|---|---|---|

EXTRA 4000 | Cyanoacrylate-based (Instant adhesives) | Metal composite materials Plastics | -30~70℃ | Acupressure for more than 30 seconds | Finger Pressure | 2g×5 |

F11 | Epoxy-based two-component mixture | Metal composite materials Plastics | -30~130℃ | Pressurise at 100°C for 2 hours. | 50~150 | 100g |

F31 | Epoxy-based two-component mixture | Metal composite materials Plastics | -30~80℃ | Pressurised at room temperature for 24 hours. | 50~150 | 100g |

Coating Material

If the measurement is to be carried out in hot and humid areas or over a long period of time, a damp-proofing agent should definitely be used.

| Type | Components | Thermal Deformation Temperature(℃) | Remarks | Contents per Set(g) |

|---|---|---|---|---|

A-1 | Butyl rubber | -30~170℃ -50~200℃ | Wear pressure with form of clay | 1000g |

TSE397 | Silicone | -55~200℃ | General and high temperature purpose | 100g |

Related Products

-

Kamoi Kakoshi Benkei Masking Tape for Construction/Painting

-

Tosei Sharyo 100HB2,600HB2 Series Heavy Duty Caster

-

U_RD CTT-CLS-CV series Data conversion equipment

-

UHT Corporation No.6 Wheel Cover For The Spindle

-

Mikasa MVH-209DSZ Reversible Compactor

-

INOAC High Standard Seal Sponge For Road Construction