Japan, Sika

Sika SC-PS2 Two-component Polysulfide-based Construction Sealant

Made in Japan

Manufacturer: Sika

Model: SC-PS2

This two-component sealant cures through a chemical reaction between the main agent and hardener, and is a low modulus type with low tensile stress. After curing, it has excellent weatherability, design, and joint adhesion.

Sealing material properties

| Sealing material properties | ||||||

| Exterior | Base | Paste | ||||

| Hardener | Liquid | |||||

| Color master | Paste | |||||

| Mixing ratio | Base: Hardener: Color master | 100 : 17.9 : 4.0 | ||||

| Performance based on JIS A5758 | Slump (mm) | Vertical | 5 ̊C | 0 | ||

| 50 ̊C | 0 | |||||

| Beside | 5 ̊C | 0 | ||||

| 50 ̊C | 0 | |||||

| Elastic recovery (%) | 90 | |||||

| Being covered | Aluminum | |||||

| Tensile stress (N/mm²)* | 23 ̊C | 0.3 | ||||

| -20 ̊C | 0.4 | |||||

| Adhesion under constant elongation | 23 ̊C | NF | ||||

| -20 ̊C | NF | |||||

| Adhesion after compression heating/tensile cooling | NF | |||||

| Adhesion after exposure to artificial light | – | |||||

| Adhesion under constant elongation after emersion in water | NF | |||||

| Volume loss (%) | 4.5 | |||||

| Durability distinction | 8020 | |||||

| Reference properties | Validity period (month) | 6 | ||||

| Extrudability (seconds) | 5 ̊C | 4 | ||||

| 23 ̊C | 2 | |||||

| Available time (time) | Specification | Low temparature | Medium temparature | High temperature | ||

| 5 ̊C | 4 | – | – | |||

| 23 ̊C | 2 | 3 | 4 | |||

| 35 ̊C | – | – | 2 | |||

| Touch drying time (23 ̊C – time) | Within 18 | Within 18 | Within 24 | |||

| Density (g/mL) | 12 | |||||

| H type tensile adhesion | Being covered | Condition | Stress/Elongation | 50% tensile stress N/mm² |

Maximum tension N/mm² |

Elongation at maximum load (%) |

| Aluminum | After health care | 23 ̊C | 0.24 | 0.99 | 750 | |

| After heating | 23 ̊C | 0.26 | 1.03 | 650 | ||

| After water immersion | 23 ̊C | 0.24 | 0.91 | 750 | ||

| Mortar | After health care | 23 ̊C | 0.23 | 0.72 | 550 | |

| After heating | 23 ̊C | 0.25 | 0.81 | 530 | ||

| After water immersion | 23 ̊C | 0.23 | 0.81 | 550 | ||

| Glass | After health care | 23 ̊C | – | – | – | |

| After heating | 23 ̊C | – | – | – | ||

| After water immersion | 23 ̊C | – | – | – | ||

List of Matching Individuals and Positions

| List of Matching Individuals and Positions | ||||||

| Working Joints | Curtain wall | Metal Curtain Wall | Vertical method | Joints around glass | ||

| Seamless vertical joint | ||||||

| Panel method | Joints between panels | |||||

| Joints around glass | ||||||

| PC Curtain Wall | Stone Pre-Setting | Joints between the PC panels | O | |||

| Tile Pre-Setting | Joints around window frame | |||||

| Painting/Spraying | Joints around glass | |||||

| Various Exterior Panels | ALC Panels (Vertical Wall Locking, Horizontal Wall Anchoring Method) | Joints between panels Joints around window frame Joints with clearance |

With paint | |||

| Without paint | ||||||

| Painted Aluminum Panels | Forced Drying | Joints between panels | ||||

| Baking Paint Coating | ||||||

| Painted steel plate | Forced Drying | Joints between panels | O | |||

| Baking Paint Coating | Joints around window frame | O | ||||

| Enamel-coated steel sheet | Joints between panels | O | ||||

| Joints around window frame | O | |||||

| GRC, Extruded cement panel (ECP) | Joints between panels Joints around window frame |

With paint | ||||

| Without paint | △ | |||||

| Metal Insulated Sandwich Panels | Joints between panels | |||||

| Glazing (ceramics) | Single-Volume | Joints around glass | ||||

| Consecutive-Volume | ||||||

| Glass Butt Joint | ||||||

| Metal fittings and fixtures | Factory seals around fittings | Drainage – Plate joints | △ | |||

| Joints between fittings | ||||||

| Factory seal | Sealant receiver | ※1 | ||||

| Cornice | Metal Cornice | Cornice gap | ||||

| Stone Cornice | Cornice gap | ◎ | ||||

| Pre-cast Concrete Cornice | Cornice gap | O | ||||

| Concrete wall | Structural slit | Joints in structural slits | Painted | |||

| Without paint | ||||||

| Nonworking Joints | RC and PC walls | Joints and joints Crack-inducing joints Joints around window frame |

Painted | |||

| Without paint | ◎ | |||||

| Wet stone cladding (including GPC jointing) | Stone joints (excluding marble) | ◎ | ||||

| Marble joints | ◎ | |||||

| Joints around window frame | ◎ | |||||

| Tiling | Tile joints | ◎ | ||||

| Joints under tile frame | O | |||||

| Joints around window frame | ◎ | |||||

| Panel Exterior | ALC thin panel | Joints between panels | Painted | |||

| Without paint | ||||||

| Various Joints Except for Exterior Walls | Rooftop | Terminal treatment of sheet waterproofing, etc. | ||||

| Floor | Concrete | Slit joints | ||||

| Stone and tile flooring | Stone tile joints | |||||

| PC panel (including PC stepped floor panel) | Joints between PC panels | |||||

| Wet area | Bathrooms & Bathtubs | |||||

| Kitchen cabinets and sinks | ||||||

| Washbasin area | ||||||

| Drain area – Penetrating pipe area | Painted | |||||

| No paint | ||||||

| Around handrail and other pillar legs | Painted | |||||

| No paint | O | |||||

| Interior wall (Mashiri) destination | ||||||

| Coated waterproofing underneath | ||||||

Related Products

-

Kamoi Kakoshi No.3303-EV Masking Tape for Structural Sealing

-

Kyowa KFGS 120Ω Triaxial, 0°/90°/45° stacked rosette for stress analysis KFGS Series General-purpose Foil Strain Gages

-

NAGANO KEIKI ZT60w Detachable Digital Pressure Gauge

-

Tsugaru Kogyo No.4020(1.1m)/4022(1.5m)/4023(2.0m) Pai Pile 1.1m/1.5m/2.0m

-

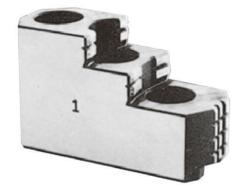

KITAGAWA HB series Chuck Parts

-

Kakuta No.HV151B Hold Down Clamp