Japan, Steel Material, Sumitomo Denko

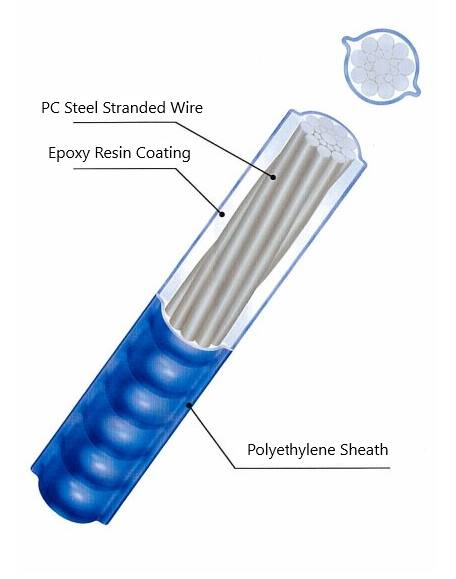

Sumitomo QS-110026-VE Moisture Curing Pre-grouted PC Steel Material

Product Made in Japan

Manufacturer: Sumitomo

Model: QS-110026-VE

A tension material for inner cables with a resin grout applied to the surface of the PC steel material and a polyethylene (PE) sheath, eliminating the need for on-site grouting.

Furthermore, since the curing speed is less affected by temperature, there is no need to use different types of resin depending on the temperature and material.

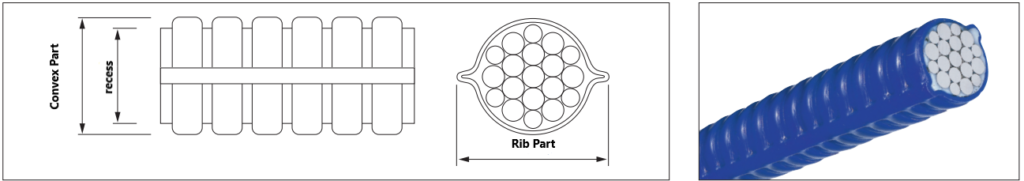

Shape

| Designation | Sheath Diameter (mm or more) | Thickness of Convex Sheath (mm, standard value) | Concave Sheath (mm, standard value) | Tolerance (mm or more) | Rib Section (mm or less) | Unit Mass (kg/km) | Maximum Test Force (kN) |

|---|---|---|---|---|---|---|---|

| 19 strands ≥ 17.8 | 25.0±2.0 | 20.5+2.0−1.5 | 0.5 | 31.0 | 1.0 | 1,880 | – |

| 19 strands ≥ 19.3 | 26.0±2.0 | 21.5+2.0−1.5 | 0.5 | 33.0 | 1.0 | 2,180 | – |

| 19 strands ≥ 21.8 | 29.0±2.0 | 24.5+2.0−1.5 | 0.5 | 36.0 | 1.0 | 2,790 | – |

| 19 strands ≥ 28.6 | 36.0±2.0 | 31.5+2.0−1.5 | 0.5 | 45.0 | 1.2 | 4,520 | – |

| 19 strands ≥ | 37.0±3.0 | 32.5±3.0 | 0.5 | 45.0 | 1.2 | 4,584 | 1139 (Type 29.0) |

*Note: High-strength strands are used, and the technology complies with the JSCE-E145-2013 standards of the Japan Society of Civil Engineers.

Mechanical Properties for Type 29.0 (Maximum Test Force: 1139kN):

| Designation | Diameter (mm) | Tolerance (mm) | Tensile Test Relaxation Value (% or less) | Nominal Cross-Section Area (mm²) | Unit Mass (kg/km) | Strength Level (N/mm² or more, reference) | Test Force for 0.2% Permanent Elongation (kN or more) | Maximum Test Force (kN or more) | Elongation (% or more) |

|---|---|---|---|---|---|---|---|---|---|

| Type 29.0 (Maximum Test Force: 1139kN) | 29.0 | +0.6, -0.25 | 3.5 | 2,080 | 547.5 | 4,293 | 2.5 | 1139 | 2080 |

Characteristics of Moisture Hardening Elastomer Resin for PC Steel

| Test Item | Sample | Heating Condition | Duration | Frequency | Quality Requirement |

|---|---|---|---|---|---|

| Viscosity | A mixture of moisture-curing epoxy resin with 2% water | 90°C | 48 hours | Once per batch | 150Pa·s or higher, 600Pa·s or lower |

| Durometer D Hardness | Randomly extracted from specified production batches | 85°C, 95% RH | 800 hours | Periodic (≥ 1/year) | Type D hardness of 50 or higher |

| Curing Shrinkage | – | 85°C, 95% RH | 800 hours | Periodic (≥ 1/year) | 1.0% or less |

Quality Requirements and Testing Methods

| Test Item | Quality Requirement | Testing Method |

|---|---|---|

| Density | 942kg/m³ or above | JIS K7112 |

| Tensile Breaking Strength | 20MPa or above | JIS K6922-2 |

| Vicat Softening Point | 115°C or above | JIS K7206 |

| Tensile Breaking Strain | 300% or above | JIS K6922-2 |

| Durometer D Hardness | 60 or above | JIS K7215 |

| Cold Resistance | -60°C or below | JIS K7216 |

Characteristics of thermosetting Elastrol resin for PC steel| Test Item | Resin Type | Heating Condition | Frequency | Quality Requirement |

|---|---|---|---|---|

| Viscosity | Type D | Room Temperature | Once per resin manufacturing batch | 300 or above |

| 80°C, 15 hours | ||||

| 80°C, 30 hours | ||||

| 90°C, 45 hours | ||||

| 95°C, 45 hours | ||||

| Durometer D Hardness | 80℃,75 Hours | Room Temperature, 75 hours | Periodic (≥ 1/year) | |

| 80°C, 150 hours | ||||

| 90°C, 150 hours | ||||

| 95°C, 150 hours | ||||

| Curing Shrinkage | ||||

| Periodic (≥ 1/year) |

| Type | Diameter (mm) | Maximum Test Force (kN above) | Test Force for 0.2% Permanent Elongation (kN above) | Unbonded Basic Outer Diameter (mm) | Coating Standard Thickness (mm) | Reference Standard Unit Mass (kg/km) | Grease Standard Mass (kg/km) | Coating Material Standard Mass (kg/km) |

|---|---|---|---|---|---|---|---|---|

| 7-wire strands (2 & 3) | 12.7 | 183 | 156 | 16.2 | 1.25 | 864 | 35 | 55 |

| 15.2 | 261 | 222 | 18.7 | 1.25 | 1,219 | 50 | 68 | |

| 19-wire strands (4, 5, 6, & 7) | 17.8 | 387 | 330 | 21.8 | 1.50 | 1,797 | 60 | 85 |

| 19.3 | 451 | 387 | 23.3 | 1.50 | 2,091 | 70 | 90 | |

| 21.8 | 573 | 495 | 25.8 | 1.50 | 2,662 | 80 | 100 | |

| 28.6 | 949 | 807 | 33.3 | 1.50 | 4,517 | 149 | 139 |

Characteristics of Michelincy

| Property | Test Method | Characteristic Value/Example |

|---|---|---|

| Density (kg/m³) | JIS K7112 | 944 |

| Tensile Breaking Stress (MPa) | JIS K6922-2 | 23.7 |

| Tensile Breaking Strain (%) | JIS K6922-2 | 620 |

| Durometer Hardness (Shore D) | JIS K7215 | 64 |

| Vicat Softening Point (℃) | JIS K7206 | 118 |

| Cold Resistance Test (℃) | JIS K7216 | -70 or below |

Characteristics of grease

| Property | Test Method | Characteristic Value/Example |

|---|---|---|

| Flexibility (25°C, 60 cycles) | JIS K2220 | 283 |

| Drop Point (℃) | JIS K2220 | 203 |

| Copper Plate Corrosion | JIS K2220 | Pass |

Request the quotation for Simitomo