Japan, Tanitec

Tanitec HSS, MSS, TiN, Nice Shot Metal Saw

Product Made in Japan

Manufacturer: Tanitec

Model: HSS, MSS, TiN, Nice Shot (Metal Saw)

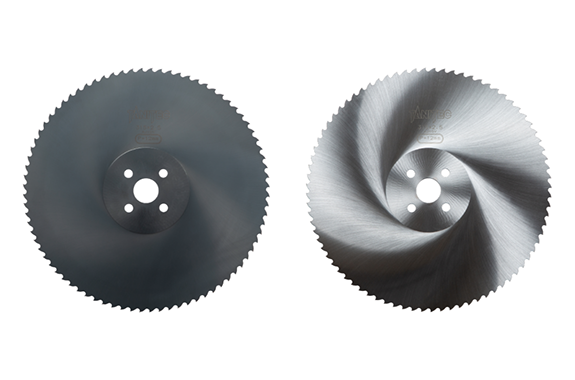

HSS Metal Saw

You can use our standard model, HSS Metal Saw for cutting of general materials such as normal steels, carbon steels and so on. TANITEC adopted the special surface treatment at first time in Japan that makes a layer of iron oxide (Fe3O4) to the blade surface. It enhances not only lubrication oil to be cooling-off, also the protection from depositing chips to the blade tooth, and it is successful in the improvement of the cutting life.

MSS Metal Saw

We coated MSS Metal Saw, High Speed Steel cold saw with Chromium and Nickel by our special technology. The special coating prevents it from rusting, wearing and depositing of the chips on the blade tooth, therefore, MSS Metal Saw is better at cutting of alloy tool steel or special steel even stainless steel which is very tough to be cut.

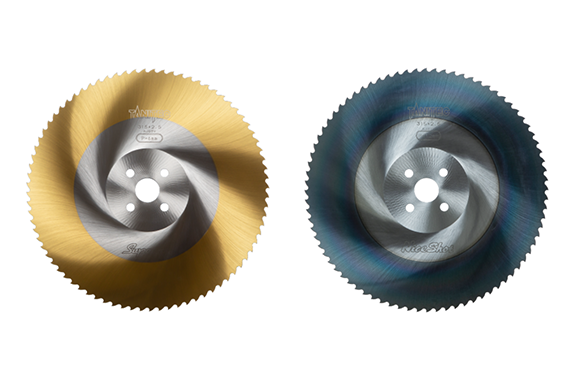

TiN Metal Saw

We coated TiN Metal Saw with titanium and nitrogen compound by ionic plating process. The hardness of blade surface can reach from HV2000 to 2500. The coating helps not only for its excellent abrasion resistance also for minimizing the chips deposition on the blade teeth.

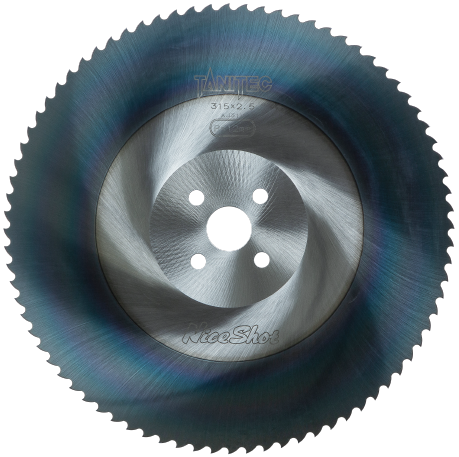

Nice Shot

The chromium coating reduces frictional coefficient and improves slip factor against cut material. The coating also prevents the metal from depositing and seizing the teeth and makes a beautiful cutting surface. Besides it has approx. twice of tool life, compared with our HSS coated blade saw. Best shot has great effects for automotive parts, machinery parts such as chromium steel, chromium molybdenum and stainless steel which is easily deposited and seized to the teeth.

Size and pitch chart

| Type | Pipe | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Material | Iron・stainless steel | Maximum cutting size. | |||||||

| Size | Under2 | 2~3 | 4 | 5~6 | 6~8 | 8~9 | |||

| Pitch | 3 | 4 | 5 | 6 | 8 | 10 | |||

| Saw size | 250 | 260 | 200 | 160 | 120 | 100 | 80 | φ75・70×70 | |

| 280 | 280 | 220 | 180 | 140 | 110 | 90 | φ75・70×70 | ||

| 300 | 300 | 220 | 180 | 160 | 120 | 90 | φ90・70×70 | ||

| 315 | 320 | 240 | 180 | 160 | 120 | 110 | φ90・70×70 | ||

| 350 | 360 | 280 | 220 | 180 | 140 | 110 | φ115・100×100 | ||

| 360 | 360 | 280 | 220 | 180 | 140 | 110 | φ115・100×100 | ||

| 370 | 360 | 280 | 220 | 180 | 140 | 110 | φ115・100×100 | ||

| 385(380) | 400 | 300 | 240 | 200 | 140 | 110 | φ120・110×100 | ||

| 400 | – | 300 | 240 | 200 | 160 | 120 | φ120・110×100 | ||

| 420 | – | 320 | 260 | 220 | 160 | 120 | φ120・110×100 | ||

| 450 | – | 340 | 280 | 220 | 180 | 140 | φ150・150×100 | ||

| Type | Flat bar | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Iron・stainless steel | Maximum cutting size. | ||||||||||

| Size | Under3 | 4~5 | 6~15 | 16~20 | 20~40 | 40~55 | 55~70 | 70~80 | ||||

| Pitch | 3 | 4 | 5 | 6 | 8 | 10 | 14 | 16 | ||||

| Saw size | 250 | 260 | 200 | 160 | 120 | 100 | – | – | – | 70×20 | ||

| 280 | 280 | 220 | 180 | 140 | 110 | – | – | – | 70×20 | |||

| 300 | 300 | 220 | 180 | 160 | 120 | – | – | – | 125×25 | |||

| 315 | 320 | 240 | 180 | 160 | 120 | – | – | – | 125×25 | |||

| 350 | 360 | 280 | 220 | 180 | 140 | 110 | 80 | – | 160×60 | |||

| 360 | 360 | 280 | 220 | 180 | 140 | 110 | 80 | 70 | 160×60 | |||

| 370 | 360 | 280 | 220 | 180 | 140 | 110 | 80 | 70 | 160×60 | |||

| 385(380) | 400 | 300 | 240 | 200 | 140 | 110 | 90 | 70 | 160×60 | |||

| 400 | – | 300 | 240 | 200 | 160 | 120 | 90 | 80 | 200×70 | |||

| 420 | – | 320 | 260 | 220 | 160 | 120 | 90 | 80 | 200×70 | |||

| 450 | – | 340 | 280 | 220 | 180 | 140 | 100 | 90 | 200×80 | |||

| Type | Angle | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Material | Iron・stainless steel | Maximum cutting size. | |||||||

| Size | Under2 | 2~3 | 3~4 | 4~6 | 6~8 | 8~9 | |||

| Pitch | 3 | 4 | 5 | 6 | 8 | 10 | |||

| Saw size | 250 | 260 | 200 | 160 | 120 | 100 | 80 | 70×70 | |

| 280 | 280 | 220 | 180 | 140 | 110 | 90 | 70×70 | ||

| 300 | 300 | 220 | 180 | 160 | 120 | 90 | 90×70 | ||

| 315 | 320 | 240 | 180 | 160 | 120 | 100 | 90×70 | ||

| 350 | 360 | 280 | 220 | 180 | 140 | 110 | 100×100 | ||

| 360 | 360 | 280 | 220 | 180 | 140 | 110 | 100×100 | ||

| 370 | 360 | 280 | 220 | 180 | 140 | 110 | 100×100 | ||

| 385(380) | 400 | 300 | 240 | 200 | 140 | 110 | 100×100 | ||

| 400 | – | 300 | 240 | 200 | 160 | 120 | 120×100 | ||

| 420 | – | 320 | 260 | 220 | 160 | 120 | 120×100 | ||

| 450 | – | 340 | 280 | 220 | 180 | 140 | 150×100 | ||

| Type | Solid | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Iron・stainless steel | Maximum cutting size. | ||||||||||

| Size | Under20 | 20~30 | 30~50 | 50~60 | 60~70 | 70~80 | 80~100 | 100~120 | ||||

| Pitch | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | ||||

| Saw size | 250 | 120 | 100 | 80 | – | – | – | – | – | 50 | ||

| 280 | 140 | 110 | 90 | 70 | 64 | – | – | – | 70 | |||

| 300 | 160 | 120 | 90 | 80 | 70 | – | – | – | 70 | |||

| 315 | 160 | 120 | 100 | 80 | 70 | – | – | – | 70 | |||

| 350 | 180 | 140 | 110 | 90 | 80 | 60 | – | – | 80 | |||

| 360 | 180 | 140 | 110 | 90 | 80 | 70 | – | – | 80 | |||

| 370 | 180 | 140 | 110 | 100 | 80 | 70 | – | – | 80 | |||

| 385(380) | 200 | 140 | 110 | 100 | 90 | 70 | – | – | 80 | |||

| 400 | 200 | 160 | 120 | 100 | 90 | 80 | 70 | – | 100 | |||

| 420 | 220 | 160 | 120 | 110 | 90 | 80 | 70 | – | 100 | |||

| 450 | 220 | 180 | 140 | 110 | 100 | 90 | 80 | 70 | 120 | |||