Japan, Tokyo Ko-on Denpa

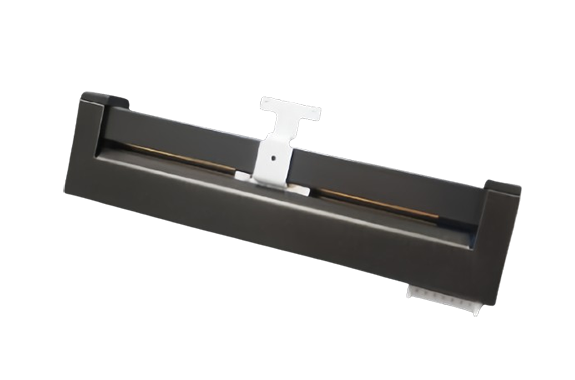

Tokyo Ko-on Denpa FA-9100 Series Manual Control Fader

Made in Japan

Manufacturer: Tokyo Ko-on Denpa Co., Ltd.

Model: FA-9100 Series

Features

Au-plated contact materials.

Horizontal style control-bar design (Protection against dust).

Durable system which adopted the shaft of the high quality.

For accurate adjustment (51positions). For reproducible necessary operation.

Electrical Specifications (Initial Value)

| Electrical specifications (initial value) | FA-9100 Series |

|---|---|

| Products | FA-910*-* |

| Number of circuits | 2 (Standard) |

| Circuit method | Potentiometer circuit |

| Total resistance (1-2), (7-6) | 10kohm |

| Total resistance tolerance | ±3% |

| Attenuation [Load: high] | 0, 1, 2, 3, …(1dB step)…, 40, 42, 44, 46, 48, 50, 55, 60, 65, 70, cut off |

| Attenuation accuracy [Load: high] | 0~20dB: ±0.2dB ~30dB: ±0.4dB ~40dB: ±0.6dB |

| Matching accuracy | 0~20dB: 0.5dB ~30dB: 0.7dB ~40dB: 1.0dB |

| Insertion loss | 0.5dB or less |

| Cut off (15kHz) | 90dB Min. |

| Voltage proof | 1 Min. at AC100V |

| Insulation resistance | 50Mohm or more at DC250V |

| Max rating | 0.1W |

| Maximum input voltage | DC20V or less |

| Sliding noise level | 47mV or less (by JIS C 6443) |

| Sliding life | 200,000 Cycles Min. (18cycles/min, Insertion loss: 1dB or less) |

| Connector (7pin) | B7B-EH (JST) |

Mechanical Specifications (Initial Value)

| Mechanical specifications (Initial value) | FA-9100 Series |

|---|---|

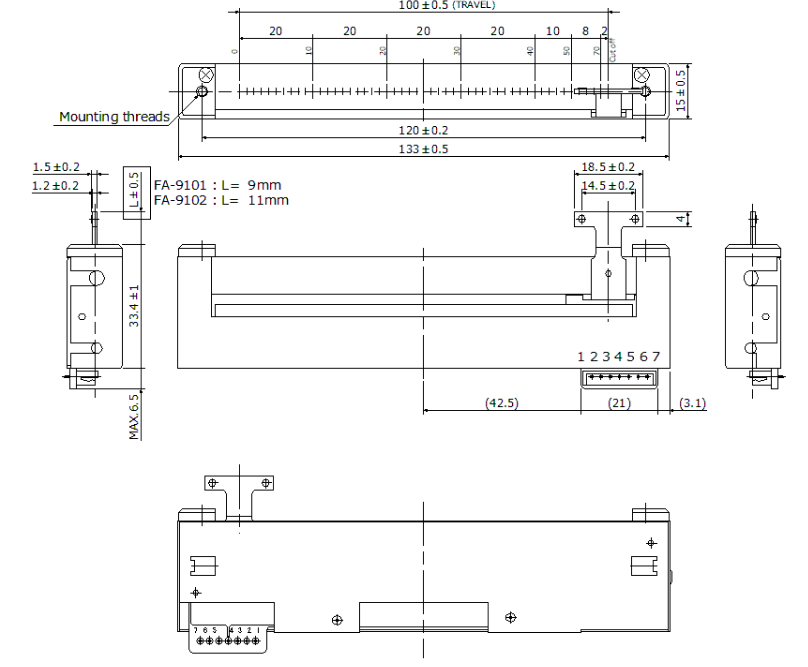

| Travel (Stroke) length | 100mm ±0.5mm |

| Operating force | 0.1 to 0.3N (Standard), 0.2 to 0.4N (High operating force) |

| Mechanical clicks | Without |

| Strength Nut-Attached | 100Ncm |

| Attached parts | M3 screw / 4-40UNC screw (Length: Panel thickness + 3mm) |

| Stopper strength | 40N |

| Push-pull strength | 40N |

| Alignment to the center | ±0.5mm (State not to pressure control-bar, Measurement position: Mounting surface) |

General Specifications

| General specifications | FA-9100 Series |

|---|---|

| Temperature range | -10 to +70 degrees C (Operating), -15 to +75 degrees C (Storage) |

| Relative humidity | 90%RH (No condensation) |