Bending, Japan, Toyo Kensetsu Kohki

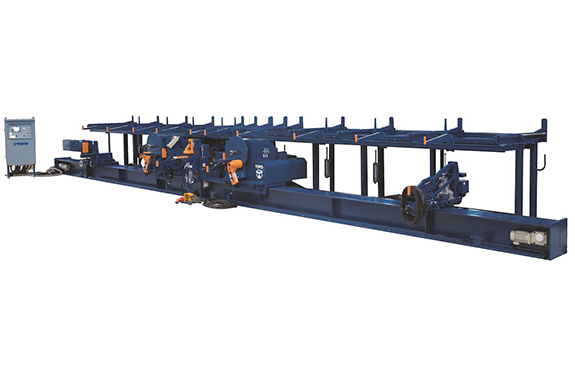

TOYO KENSETSU KOHKI TBM-41-1ASV DOUBLE BENDER

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TBM-41-1ASV

Features

- AUTO REBAR BENDING

- Bar (Large)

- Reduce manpower

- High strength rebar processing

- Rebar fabrication

- Precast concrete

| Model | TBM-41-1ASV |

|---|---|

| Capacity | SD390: D19-4 ~ D41-1

SD490: D19-4 ~ D41-1 |

| Required breaker capacity | 100A |

| Bending unit revolution | 4.7/5.7rpm (50/60Hz) |

Machine & Processing

Specifications

| Specifications | TBM-41-1ASV (10m) |

| Required breaker capacity | 100A |

| Min. distance between fulcrum centers | 1,450mm |

| Max, distance between fulcrum centers | 8,200mm |

| Bending angle | 15~180° (large radius:15~90°) |

| Bending unit revolution | 4.7/5.7 rpm(50/60Hz) |

| Total motor capacity | 15.5kW (including air-compressor) |

| Dimensions (LXWXH) | 11,545×2,410×1,375mm |

| Total weight | 6,000kg |

Similtaneous Max. Bending Quantity (pcs)

| Rebar diameter | D19 | D22 | D25 | D29 | D32 | D35 | D38 | D41 |

| Fulcrum roller dia. | Φ113 | Φ124 | Φ148 | Φ168 | Φ186 | Φ204 | Φ222 | Φ237 |

| SD390 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 |

| SD490 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 |

| Fulcrum roller dia. for large radius | Φ250 Φ300 Φ400 / Φ500 Φ600 / Φ700 Φ800 (make-to-order parts) | |||||||

Details

・TBM-41-1ASV is an automatic rebar bending machine which is capable of bending high-strength rebar SD490

(Yield Point: 490-625N/mm2, Tensile Strength≧620N/mm2) up to D41.

・TBM-41-1ASV is capable of bending 3 pieces of D25 at a time.

・Chucking device grabs materials, which raises the dimension accuracy of finished products.

・Shapes and dimensions can be easily set on the user-friendly touch screen.

・TBS-41-1ASV carries out bending main rebar vertically, which enables you not only to save the work space but also raise the safety.

・Number counter device is optional.”

Other items of TOYO KENSETSU KOHKI

Request the quotation for TOYO KENSETSU KOHKI

Related Products

-

BIX B-35BRM/B-35BPM/B-35BSM Socket Bits

-

Vessel No.A14 Square Double End Bit

-

Okabe B96-0110 Foamed Chamfer/Joint Strip (Expanded Polystyrene Chamfer/Joint Strip)

-

Watanabe WP-3 Front Panel Cover Accessory

-

KONAN SASC6-02-8A Air-intake And Exhaust Speed Controller Compatible With NAMUR Standards

-

Chiyoda Seiki Acetylene Cylinder Collecting Device Parallel Type Cylinder Collection Device