Bending, Japan, Toyo Kensetsu Kohki

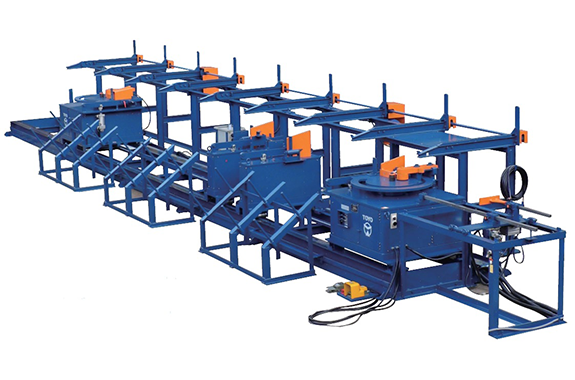

TOYO KENSETSU KOHKI TWB-40SNⅡ DOUBLE BENDER

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TWB-40SNⅡ

Features

- AUTO REBAR BENDING

- Bar (Large)

- Reduce manpower

- High strength rebar processing

- Rebar fabrication

- Precast concrete

| Model | TWB-40SNⅡ |

|---|---|

| Capacity | SD390: D16-3 ~ D38-1 SD490: D16-3 ~ D32-1 |

| Required breaker capacity | 60A |

| Bending unit revolution | 7.6/9.2rpm (50/60Hz) |

Machine & Processing

Specifications

| Specifications | TWB-40SNI (10.5m) |

| Required breaker capacity | 60A |

| Min. distance between fulcrum centers | 1,400mm |

| Max. distance between fulcrum centers | 10,500mm |

| Bending angle | 15~180° (large radius:15~90°) |

| Bending unit revolution | Low speed 5.2/6.2 rpm (50/60Hz) High speed 7.6/9.2 rpm(50/60Hz) |

| Total motor capacity | 10.4kW (including air-compressor) |

| Dimensions (LXWXH) | 13,650×3,560×1,650mm |

| Total weight | 5,800kg |

Similtaneous Max. Bending Quantity (pcs)

| Rebar diameter | D16 | D19 | D22 | D25 | D29 | D32 | D35 | D38 |

| Fulcrum roller dia. | Φ64 | Φ74 | Φ86 | Φ97 | Φ113 | Φ125 | Φ137 | Φ148 |

| SD390 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 |

| SD490 | 3 | 3 | 2 | 2 | 2 | 1 | _ | _ |

| Fulcrum roller dia. for large radius | Φ250 Φ300 Φ400 / Φ500 Φ600 / Φ700Φ800 (make-to-order parts) | |||||||

Details

・TWB-40SNⅡis suitable for bending single anchors and double anchors of D16~D38.

※It is possible to bend double anchors of D38-SD390. (Yield Point: 390-510N/mm2, Tensile Strength≧560N/mm2)

・Material is automatically supplied while finished products can be discharged by the lifts.

・One operator is enough to carry out bending long length rebars.

・2 kinds of angles can be set by dial type of setting.”