CONSTRUCTION, Japan, Turnbuckle Brace

Turnbuckle Brace

Product made in Japan

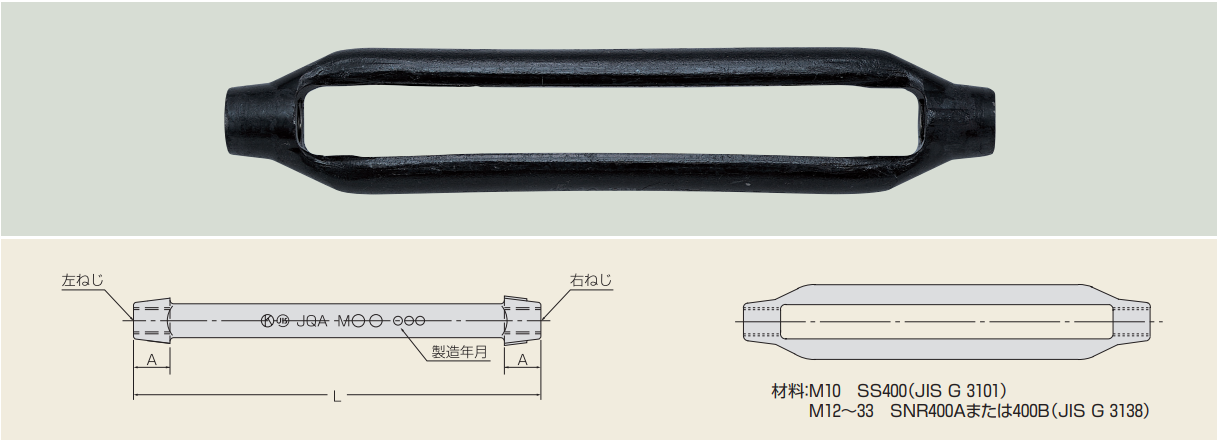

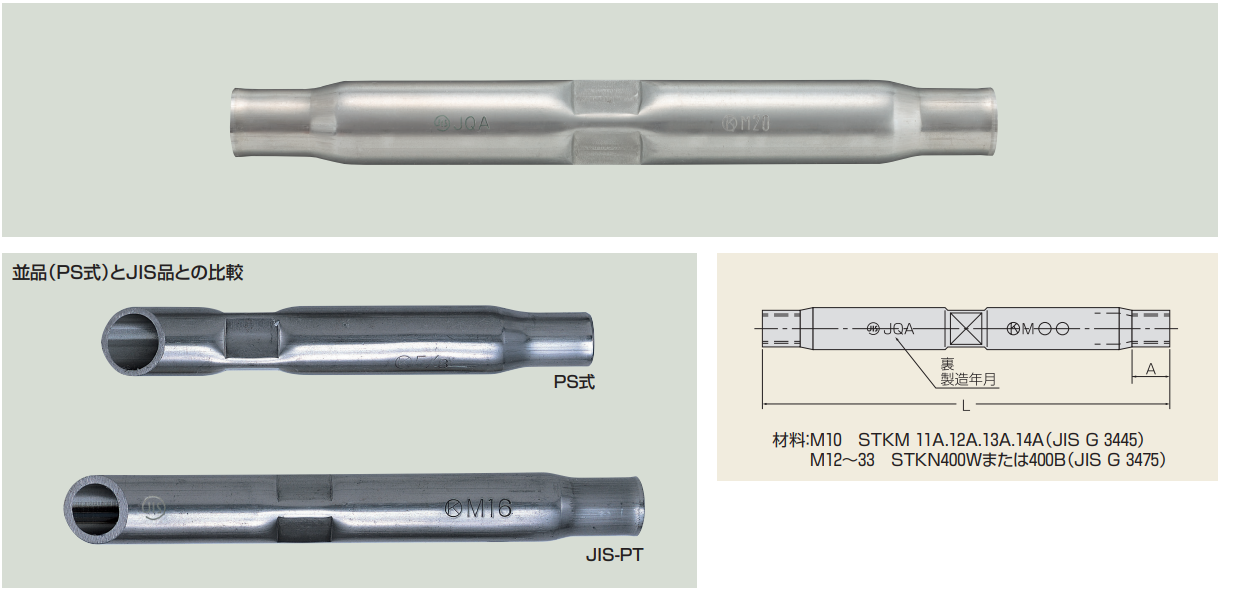

JIS Turnbuckle Brace’s Body

● Heating equally by electric heater.

● Forging high accuracy by using robots.

Split Type (ST)

Material:

- M10 SS400(JIS G 3101)

- M12〜33 SNR400A/400B(JIS G 3138)

Pipe Type (PT)

Material:

- M10 STKM 11A.12A.13A.14A(JIS G 3445)

- M12〜33 STKN400/400B(JIS G 3475)

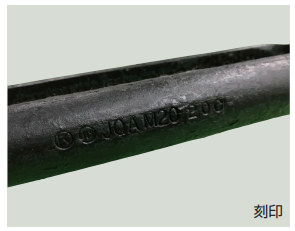

Mark of JIS frame

Mark of right thread

| Diameter | Full-Length L (mm) | Head Length A (mm) | Tensile load Min kN (tf)

| Guaranteed load kN (tf)

| Split Frame mass (kg) | Split Frame Type (PT) (Classification code: 011A1) | Measured Mass (kg) | Pipe Type (PT) (Classification code: 012A1) | ||||

| Product Code | Product Code | Product Code | Product Code | Product Code | Product Code | |||||||

| M10 | 150 | 14 or more | 30.9 (3.2) | 14.2 (1.4) | 0.153 | AB10 | UB10 | DB10 | 0.095 | ABM10 | UBM10 | DBM10 |

| M12 | 200 | 17 or more | 44.9 (4.6) | 20.7 (2.1) | 0.300 | ALSB12 | ULSB12 | DLSB12 | 0.175 | ABM12 | UBM12 | DBM12 |

| M14 | 230 | 20 or more | 61.7 (6.3) | 28.4 (2.9) | 0.480 | AB14 | UB14 | DB14 | 0.285 | ABM14 | UBM14 | DBM14 |

| M16 | 250 | 23 or more | 83.1 (8.5) | 38.3 (3.9) | 0.640 | AB16 | UB16 | DB16 | 0.416 | ABM16 | UBM16 | DBM16 |

| M18 | 280 | 25 or more | 103 (10.5) | 47.6 (4.9) | 0.900 | AB18 | UB18 | DB18 | 0.60 | ABM18 | UBM18 | DBM18 |

| M20 | 300 | 28 or more | 131 (13.4) | 60.2 (6.1) | 1.20 | AB20 | UB20 | DB20 | 0.84 | ABM20 | UBM20 | DBM20 |

| M22 | 330 | 31 or more | 161 (16.4) | 74.3 (7.6) | 1.54 | AB22 | UB22 | DB22 | 1.05 | ABM22 | UBM22 | DBM22 |

| M24 | 350 | 34 or more | 188 (19.2) | 86.8 (8.9) | 1.09 | AB24 | UB24 | DB24 | 1.37 | ABM24 | UBM24 | DBM24 |

| M27 | 400 | 38 or more | 244 (24.9) | 112 (11.4) | 2.01 | AB27 | UB27 | DB27 | 2.16 | ABM27 | UBM27 | DBM27 |

| M30 | 400 | 42 or more | 299 (30.5) | 138 (14.1) | 3.66 | AB30 | UB30 | DB30 | 2.40 | ABM30 | UBM30 | DBM30 |

| M33 | 450 | 46 or more | 369 (37.7) | 170 (17.3) | 4.95 | AB33 | UB33 | DB33 | 3.05 | ABM33 | UBM33 | DBM33 |

● The permanent deformation of the body should be within 0.5% of the body length (L) with the guaranteed load shown in the table above.

● The guaranteed load corresponds to short-term allowable stress.

*The M12 split frame is the LS type.

M24 cut threading screw

Gusset plate

Turnbuckle Brace

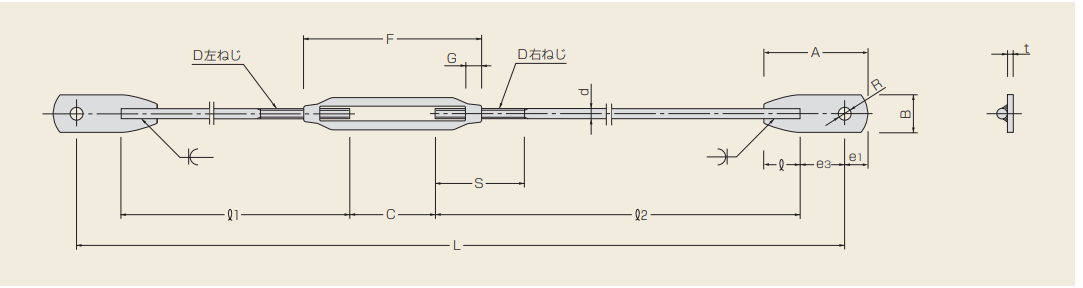

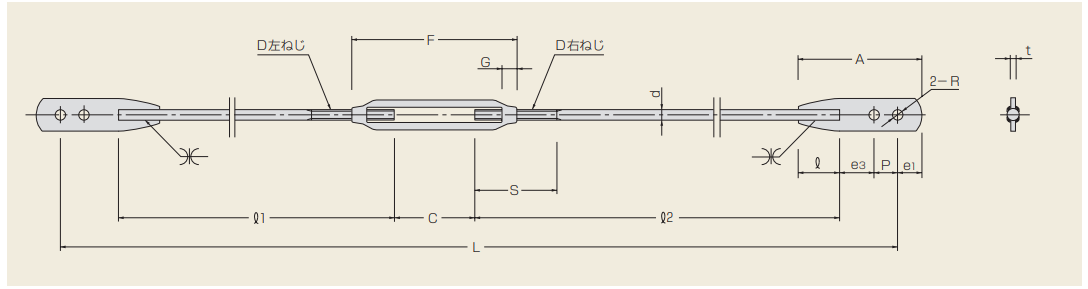

Turnbuckle Brace’s dimensions and performance (M10-M22/M24-M33)

M10〜M22

| Diameter | Bolt | Gusset plate | Body (*2) | Mounting Bolt (*3) | Middle Space | |||||||||

| Minimum diameter | Left Bolt Length (*1) | Screw Length | Plate Thickness | Plate Width | Full Length | Hole Diameter | Distance from bolt-end to the hole | e1 | Welding Length | TB Total Length | TB Head Length | Size and Number | ||

| D | d | ℓ1 | S | t | B | A | R | e3 | e1 | ℓ | F | G | C | |

| M10 | 8.87 | 500 | 75 | 4.5 | 44 | 109 | 13 | 42 | 30.5 | 36.5 | 150 | 14 | M12 x 1 | 70 |

| M12 | 10.59 | 500 | 100 | 6 | 58 | 136 | 17 | 54 | 40.5 | 41.5 | 200 | 17 | M16 x 1 | 100 |

| M14 | 12.41 | 500 | 115 | 6 | 58 | 146 | 17 | 54 | 40.5 | 51.5 | 230 | 20 | M16 x 1 | 115 |

| M16 | 14.41 | 500 | 125 | 6 | 58 | 163 | 17 | 61 | 45.5 | 56.5 | 250 | 23 | M16 x 1 | 120 |

| M18 | 16.07 | 500 | 140 | 9 | 70 | 180 | 21.5 | 68 | 50.5 | 61.5 | 280 | 25 | M20 x 1 | 140 |

| M20 | 18.07 | 500 | 150 | 9 | 70 | 195 | 21.5 | 68 | 50.5 | 76.5 | 300 | 28 | M20 x 1 | 150 |

| M22 | 20.07 | 500 | 165 | 9 | 80 | 217 | 23.5 | 75 | 55.5 | 86.5 | 330 | 31 | M22 x 1 | 165 |

M24〜M33

Diameter | Bolt | Gusset plate | Body (*2) | Mounting Bolt (*3) | Middle Space | ||||||||||

| Minimum diameter | Left Bolt Length (*1) | Screw Length | Plate Thickness | Plate Width | Full Length | Hole Diameter | Distance from bolt-end to the hole | e1 | Welding Length | Distance between 2 holes | TB Total Length | TB Head Length | Size and Number | ||

| D | d | ℓ1 | S | t | B | A | R | e3 | e1 | ℓ | P | F | G | C | |

| M24 | 21.69 | 500 | 175 | 9 | 80 | 271 | 21.5 | 73 | 51 | 87 | 60 | 350 | 34 | M20 x 2 | 170 |

| M27 | 24.69 | 500 | 200 | 9 | 92 | 278 | 21.5 | 75 | 51 | 92 | 60 | 400 | 38 | M20 x 2 | 200 |

| M30 | 37.34 | 500 | 200 | 12 | 92 | 299 | 23.5 | 86 | 56 | 97 | 60 | 400 | 42 | M22 x 2 | 200 |

| M33 | 30.34 | 500 | 225 | 12 | 102 | 321 | 23.5 | 93 | 56 | 112 | 60 | 450 | 46 | M22 x 2 | 220 |

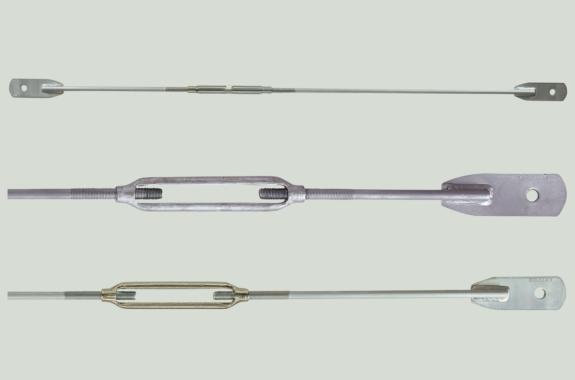

* (1) Standard for fabric, coating, chrome plating brace, hot-dip galvanizing is 300 or 500 mm.

* (2) The figure shows the split frame type, but the pipe type (JIS PT) is the same.

* (3) Mounting bolts are JIS B 1186 Class 2 high strength bolts (F10T), JIS B 1180 strength classification 10.9 or structural type high strength bolts (S10T)

Surface Treatment

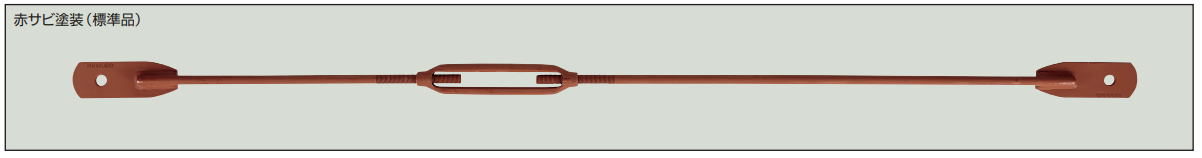

Red painting (Standard)

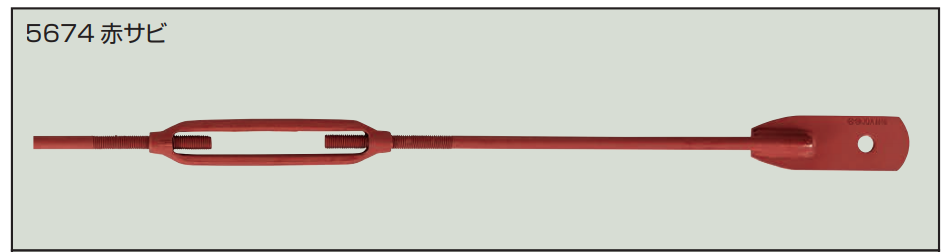

5674 Red painting

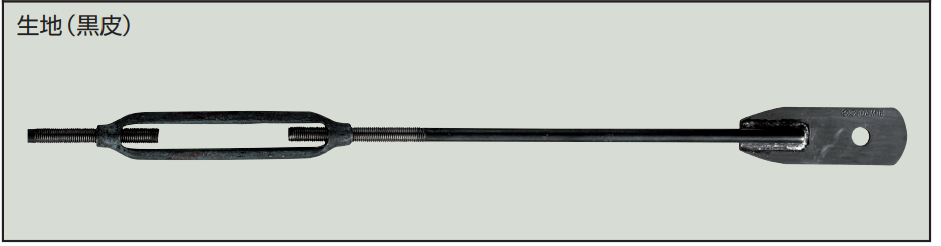

Fabric (Black)

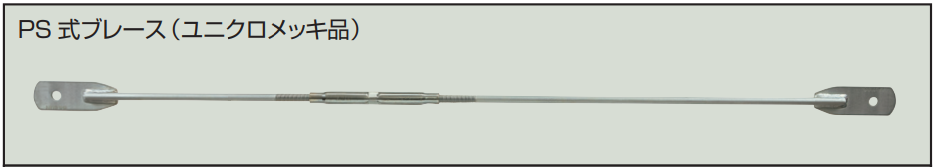

PS type brace (unichrome plated)

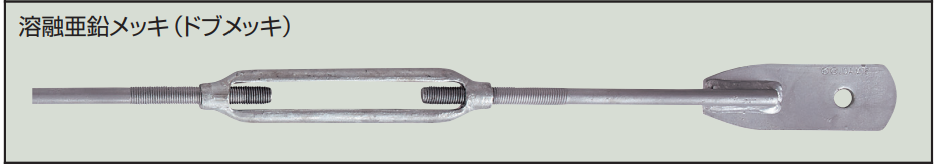

Hot-dip galvanizing

Unichrome Plating

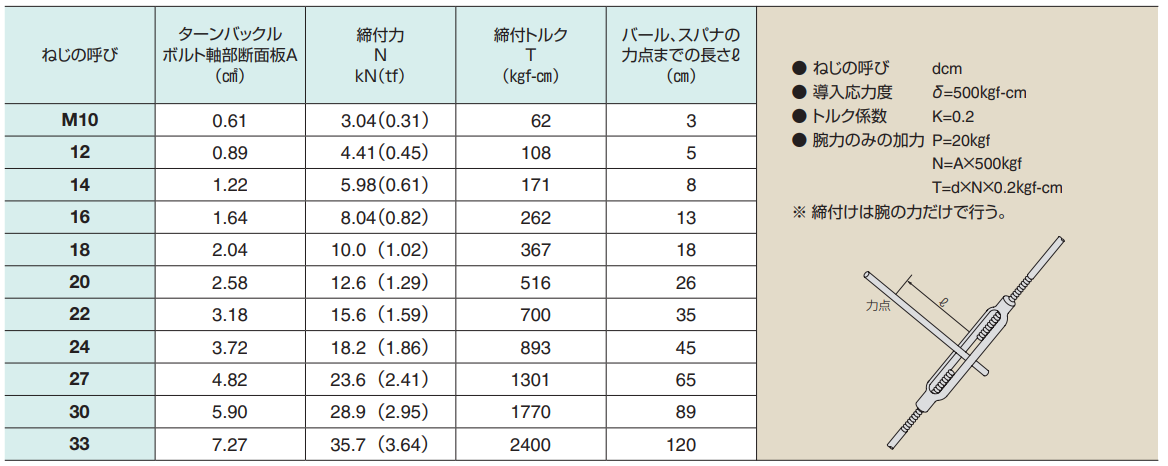

Precautions

It is desirable to use a bar or spanner with a mark or engraved at the length ℓ (cm) of the handle (see the figure below). When tightening, do not use your weight or flexion of your legs, but use only your strength.

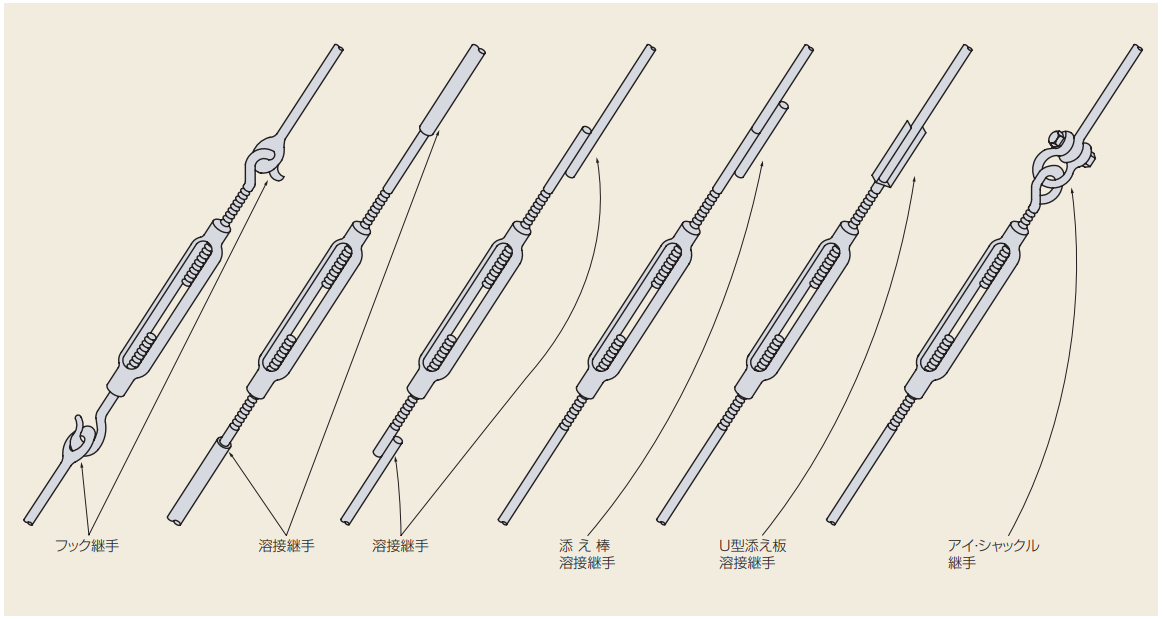

Examples