Japan, UHT CORPORATION

UHT CORPORATION Advanced performance punching machine APP series

Made in Japan

Manufacturer: UHT CORPORATION

Model: APP series (Ceramic green sheet)

Features

- Superhigh speed punching with 1800 hole/min(by PUM-25L)

- High precision punching with ±5μm

Characteristics

- -Superhigh speed / superhigh precision punching micro holes

- The newly developed superhigh speed XY axes are installed, and an electric linear punching unit realizes higher processing speed of 1800 hole/min (approx. 3 times: internal ratio).

- -The table installed with 8-axis punching units is set, suitable for the machine to develop newly and the trial production.

- 8 axes of“25 type unit”can be installed,applicable to punching various kinds of diameters.

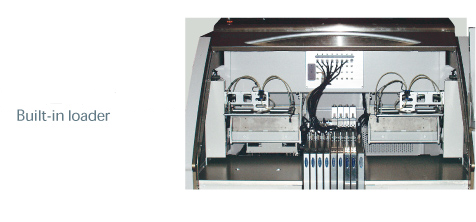

- -Automation and space saving

- Automatic loader (OP.) possible to build in, and a space saving compact machine is realized.

-

Standard Specifications

Model name APP Work Material Ceramic green sheet Thickness Max.1.0mm Punching area Max. □200mm Standard work holder □274mm×t0.6mm Type of clamp Work holder V/F clamp The number of the axis installed on punch units PU-25:8axes Capability Punching accuracy ±5μm (Position accuracy relative to the origin of the coordinate system calculated from two lateral alignment marks [reference punch holes] in the standard punching range on UHT test film) Punching speed By PUM-25L : Max. 1800 hole/min

By PU-25L : Max. 1000 hole/min

By PU-25LH/A : Max. 600 hole/min

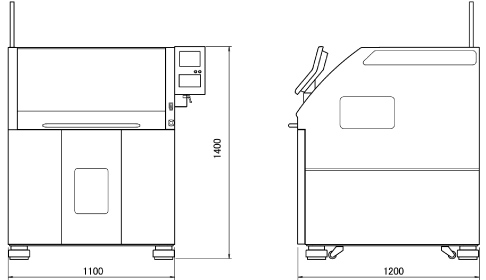

(NC punch with 1mm pitch in Y direction)Control function Control function Controller: UHT made MJUC controller Operation Graphically operated by 6.5”TFT color liquid crystal Punch data By interactive software on P/C Network Transmission of machining data from P/C to the machine through LAN centralized monitoring of the machine (up to 4units) on P/C Data 1file (Max.30000 positions) Image processing Image processing with UHT made image processing function by CCD Power 3φ AC200V ±10% 2kVA Air 0.4MPa~0.7MPa (Clean air) Machine size W1100×D1200×H1400mm Machine weight Approx. 1500kg Options

- Punching unit

- Automation (Slide loader)

- Fine θ finger

- Punch, Die, Stripper

- Internally cleaning system

Fine controlling temperature ・cleanliness

Outline Drawing