Japan, UHT CORPORATION

UHT CORPORATION G-CUT U series Cutting Machine For Laminated Ceramic Green Sheet

Made in Japan

Manufacturer: UHT CORPORATION

Model: G-CUT U8, G-CUT U12, G-CUT UW8, G-CUT UW12

Features

- High-quality cutting for materials for package substrates, module substrates, fuel cells, and etc.

- The UW type for rectangular workpieces

- From R&D through (automated) mass production

Characteristics

- Highly functional, high-performance, and high-quality cutting

- Rigid structure for different materials, thicknesses, and cutting depths High intensity LED illuminations to detect complex images

- Series lineup for double cutter holder type (type UW)

- Improved usability

- Clear view of alignment marks on a 15-inch monitor Improved usability with a 10.4-inch color touch panel

- Clean and eco-friendly dry cutting

- Automation modules(OP.)

- Retrofittable automation modules for mass production.

Standard Specifications

| Model | G-CUT U8/UW8 | G-CUT U12/UW12 | ||

|---|---|---|---|---|

| Work | Material | Laminated Ceramic Green Sheet | ||

| Thickness | Max.5.0mm(~15mm OP.) | |||

| Size | Max.□225mm | Max.□325mm | ||

| Product size | Max.□200mm | Max.□300mm | ||

| Alignment mark position | Surface/side | |||

| Capability | Positioning accuracy | ±5μm(Z,Y axis) | ||

| Processing accuracy | ±15μm(with image processing) | |||

| Cutting speed | NC: 420 cuts/min (Y feed pitch 1 mm, Z ascent 2 mm) | |||

| With image processing: 120 cuts/min (Y feed pitch 1 mm, Z ascent 30 mm) | ||||

| Cutting power | 3900N(Max. instantaneous11700N) | |||

| Stroke ・ Travel speed(Max.) ・ Resolution | ||||

| Z-axis | 60㎜ ・ 22.5m/min ・ 1μm | |||

| Y-axis | U8:400mm UW8:570mm U12:500mm UW12:670mm ・ 42m/min ・ 0.5μm | |||

| T-axis | 90°(180°270°OP.) ・ 60rpm ・ 0.000088゚ | |||

| cutter holder / cutter replacement | One touch exchange | |||

| Cutting Table | Vacuum | |||

| Image processing | Method | CCD cameras detect alignment marks on sheet surface and side. | ||

| Detection method | Binary centroid calculation / pattern matching | |||

| Camera | Two cameras, 45-deg angled | |||

| View | Approx.4.5×2.4mm(raw image) Approx.3.6×2.4mm(Image processed image) | |||

| Lighting | LED lighting | |||

| Display | 15 inch display | |||

| Control function | Control unit | UHT original controller | ||

| Operation | 10.4 inch color touch panel | |||

| Data making | Teaching on machine or data input via control PC(OP.) | |||

| Stripper | Prevents workpiece from lifting in cutting | |||

| Cutter cleaner | Cutter cleaner slides in parallel to blade for cleaning the tip | |||

| Safety device | Front: Table and Cutter door(with safety sensor) | |||

| Power source | 3φ AC200V ±10% 5kVA | |||

| Air source | 0.4~0.7MPa(clean air) | |||

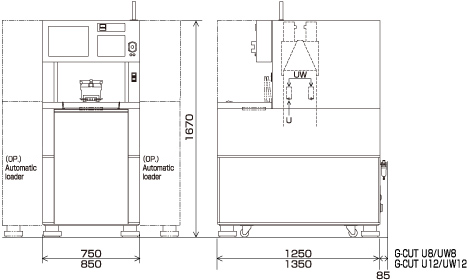

| Machine | Size | W750 × D1250 × H1670㎜ | W850 × D1350 × H1670㎜ | |

| Weight | U8:approx.1500kg UW8:approx.1550kg | U12:approx.1600kg UW12:approx.1650kg | ||

| Working condition | Temperature/Humidity | 10〜35℃(recommend 22±2℃)/40〜60% un-condensation | ||

Option

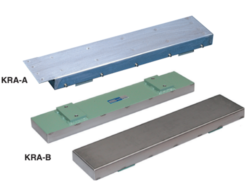

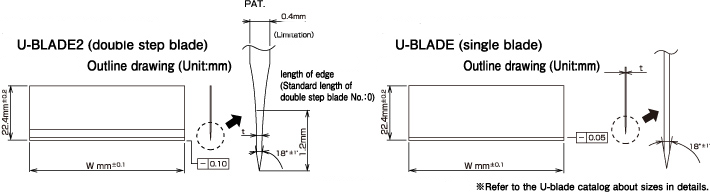

- Cutter holder/blade

- Cutting units

- Alignment unit

- Separated preheater

- Automation modules

- Power box

- Control PC & Processing data creation software

- Blade setter (for height adjustable cutter holders)

- Spare parts

Outline Drawing