Japan, UHT CORPORATION

UHT CORPORATION HP-L series Hybrid puncher

Made in Japan

Manufacturer: UHT CORPORATION

Model: HP-12150L , HP-12200L

Features

- A high performance unit enabled loading punching, drilling and routing unit at the same time.

- Offers super-high speed besides a low vibration and silence.(linear motor drive)

Characteristics

- By compound processing, high efficiency and high accuracy is realized.

- Arrangements can be omitted by processing the each stage of work at the same time and making work highly effective is achieved.

Offers a highly accurate setting positions by omitting programs. - The initial running cost is decreased by die-less and generalizing punches.

- Easy setting of the unit and tool

- Various units and various tools can be easily set according to the processing pattern and the condition.

- Wide selection from trial production to medium mass production

- This is available to trial production, many varieties small lot and medium mass production according to combination of main modules and various loaders.

Standard Specifications

| Model name | MP-12150L | MP-12200L | |

|---|---|---|---|

| Work | Material | Ceramic green sheet, etc. and work like sheet. | |

| Thickness | Max 0.5mm | ||

| Size/Sheet | Max □175mm (RRC:□180mm) | Max □225mm RC:□250mm | |

| Working area | Max □150mm | Max □200mm | |

| How to attach | Supply : Sheet : Standard work holder, Vacuum frame Roll : Vacuum frame | ||

| Punch unit(OP.) | Number of installing (in the PU-25 size) | 12axes | |

| Capability | Machining Accuracy | ±10μm(Between 2 points in 1” punched on standard UHT’s test film) | |

| Machining Speed | By PUM-25L :Max1500hole/min By PU-25L :Max1000hole/min By PU-25A :Max 600hole/min NC punch with 1mm pitch in Y direction standard V/H work holder | ||

| System | Drive method | XY-axis linear motor | |

| Control function | Control | UHT made MJUC controller | |

| Operation | 6.5″ color LCD touch panel | ||

| Punch data | Software on PC (independent of the main body) | ||

| Number of processing data memories | 1 file : Max. 30000 positions | ||

| Network | Transmission of machining data from PC to the machine through LAN. Centralized monitoring the machine operating condition (up to 4 units) on PC | ||

| Image Processing method | Image data processing is executed by the image processing function with CCD only made of UHT. | ||

| Power source | 3φ AC200V ±10% 3kVA | ||

| Air source | 0.4~0.7 MPa | ||

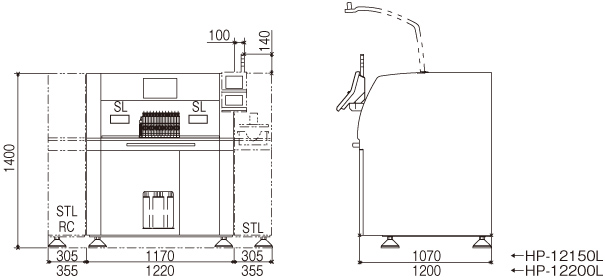

| Machine size (Body) | W | 1170mm | 1220mm |

| D | 1070mm | 1200mm | |

| H | 1400mm | 1400mm | |

| Machine weight (Body) | Approx. 1000kg | Approx. 1250kg | |

| Working condition | Temperature | 10℃~35℃ (22℃±2℃ recommended) | |

| Humidity | 40~60%(Non-dewing) | ||

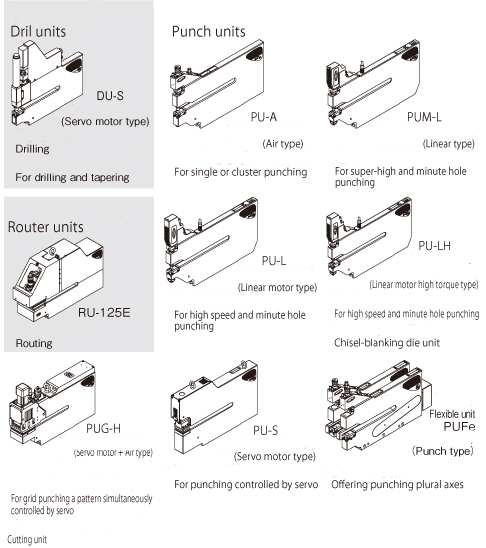

Options

- Punch setter

- Data conversion software from CAD

- Booster tank

- Metal mold(Punch, Die)

- PC

- Punch units

- Power box

- Punch break detecting software

Outline Drawing

Related Products

-

DIJET TNMG160404-KG, TNMG160408-KG, TNMG160412-KG Semi-Finishing Insert

-

Ross Asia DMC1 series double valve Safety cat. 4 PL e, internal monitoring, automatic reset

-

TONE RH30K Ratchet Handle (Socket Hold Type)

-

Vessel No.VE-5000SOP Electric Screwdriver (w/ Signal Output Function)

-

Gentos Ganz Series GZ-011 Compact Handy Work Light (150 lumens)

-

Maeda Koki FITV Type Flow Indicator