Drilling And Cutting, Japan, Unika

UNIKA BGS Stainless Steel Big One

Manufacturer: UNIKA

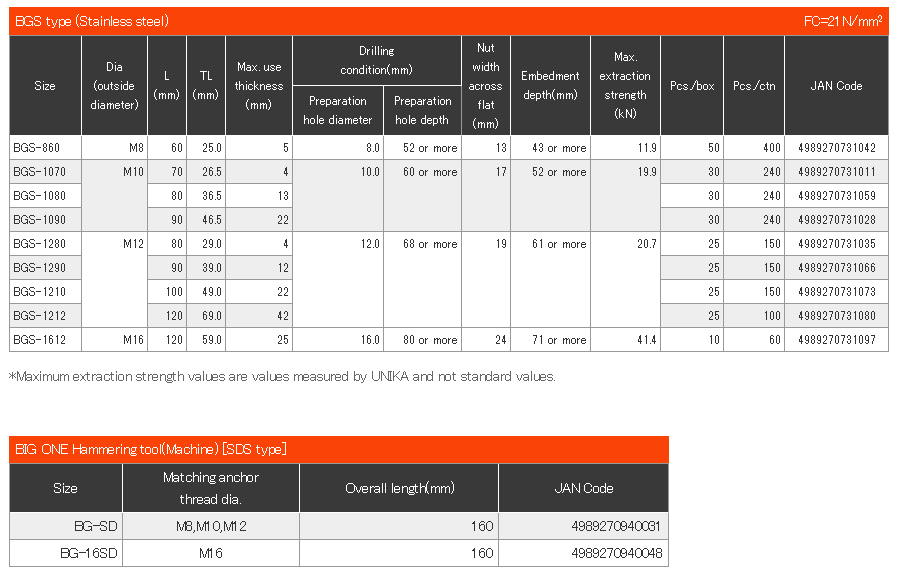

Model: BGS type (Stainless steel)/ BIG ONE Hammering tool(Machine) [SDS type]/ Different diameter high nut for Big One (Unichrome treatment)/ Different diameter high nut for Big One (Stainless steel)

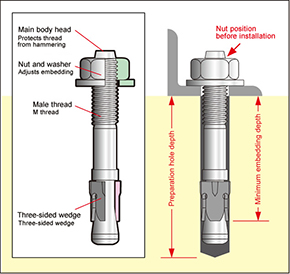

■Demonstrates reliable strength by installation with torque control and three-sided wedges.

■Overall length can be checked after installation by marking on the head.

■BGS type is completely made of stainless steel which is resistant to rust.

Used extensively even in humid places.

USES

Concrete•Stone

- Drill vertically to target surface with the determined preparation diameter and preparation hole depth.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Insert a big one.

- Hammer in until the washer contacts the installed object.

- Use a torque wrench to tighten the nut to the specified torque value.

- The three-sided wedge expands and installation is completed.

- Wear safety protection equipment such as protective glasses, a helmet etc., during installation.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Select overall length of anchor in consideration of thickness of installed object.

- Align the end face of the nut with the end of the tape to set.

- For installation, use a torque wrench to tighten to the specified torque.

■Uses

Electrical, plumbing, air-conditioning / heating duct works, elevator construction work, elevator installation work.

■Tightening torque

| Thread nominal diameter | M8 | M10 | M12 | M16 |

|---|---|---|---|---|

| Width across flat | 13mm | 17mm | 19mm | 24mm |

| Tightening torque | 15N•m | 30N•m | 45N•m | 100N•m |

■Marking on head

| Overall length(mm) | 60 | 70 | 80 | 90 | 100 | 120 |

|---|---|---|---|---|---|---|

| Marking | B | C | D | E | F | H |

Before installation

Install it after aligning the nut with the taper end section on the head of the anchor body.

Installation check

If the thread section is protruded by a height of one nut or more when the nut is tightened, it has been improperly installed. Check the preparation hole diameter and install in another position.

- Set a nut on the specified position before hammering.

- After hammering, make sure to tighten the nut with a torque wrench to the specified torque.

- It cannot be used for BGL type.

SPECIFICATION

BGS type (Stainless steel) BIG ONE Hammering tool(Machine) [SDS type]

| Size | Dia (outside diameter) | Size | Matching anchor thread dia. | |

| BGS-860 | M8 | BG-SD | M8,M10,M12 | |

| BGS-1070 | M10 | BG-16SD | M16 | |

| BGS-1080 | ||||

| BGS-1090 | ||||

| BGS-1280 | M12 | |||

| BGS-1290 | ||||

| BGS-1210 | ||||

| BGS-1212 | ||||

| BGS-1612 | M16 | |||

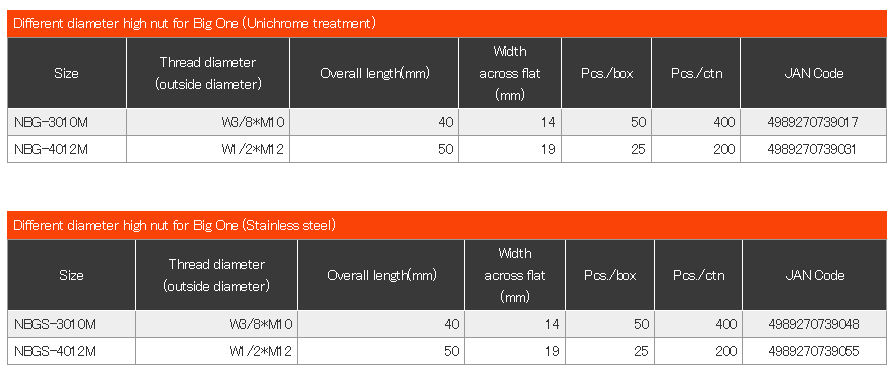

Different diameter high nut for Big One (Unichrome treatment) – Different diameter high nut for Big One (Stainless steel)

| Size | Thread diameter (outside diameter) | Size | Thread diameter (outside diameter) | |

| NBG-3010M | W3/8*M10 | NBGS-3010M | W3/8*M10 | |

| NBG-4012M | W1/2*M12 | NBGS-4012M | W1/2*M12 |

Related Products

-

TSUBOSAN Hard Case for Air File Body Files For Machine

-

TSUBOSAN SHARP CUT FILES Die Sinker’s-Assorted Files

-

TSUBOSAN TAF-SW Series Air Files Standard

-

Fujii Denko POA-S93 Industrial Safety Belt

-

KONAN CP611AR Pneumatic Cylinder Rod-out stroke Adjustable Type

-

Saitamaseiki AK-P6L Impact Drivers and Impact Wrenches