Drilling And Cutting, Japan, Unika

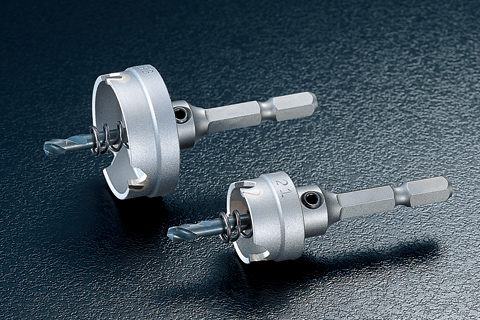

UNIKA Cordless Meta-core T.C.T Hole Saw

Manufacturer: UNIKA

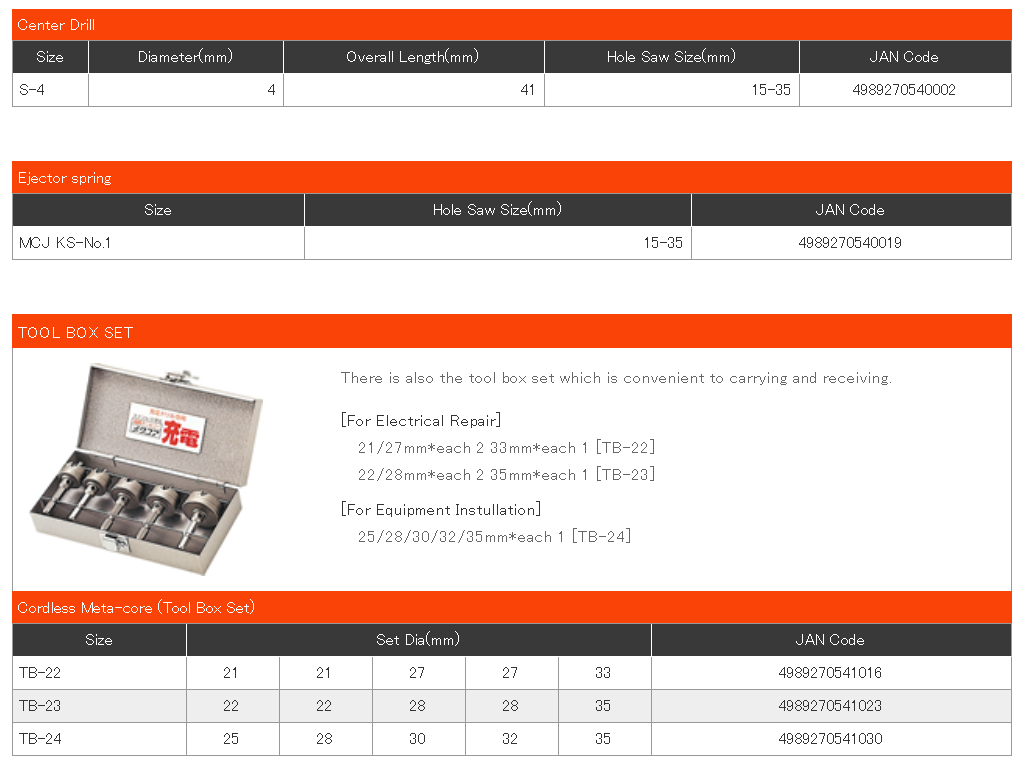

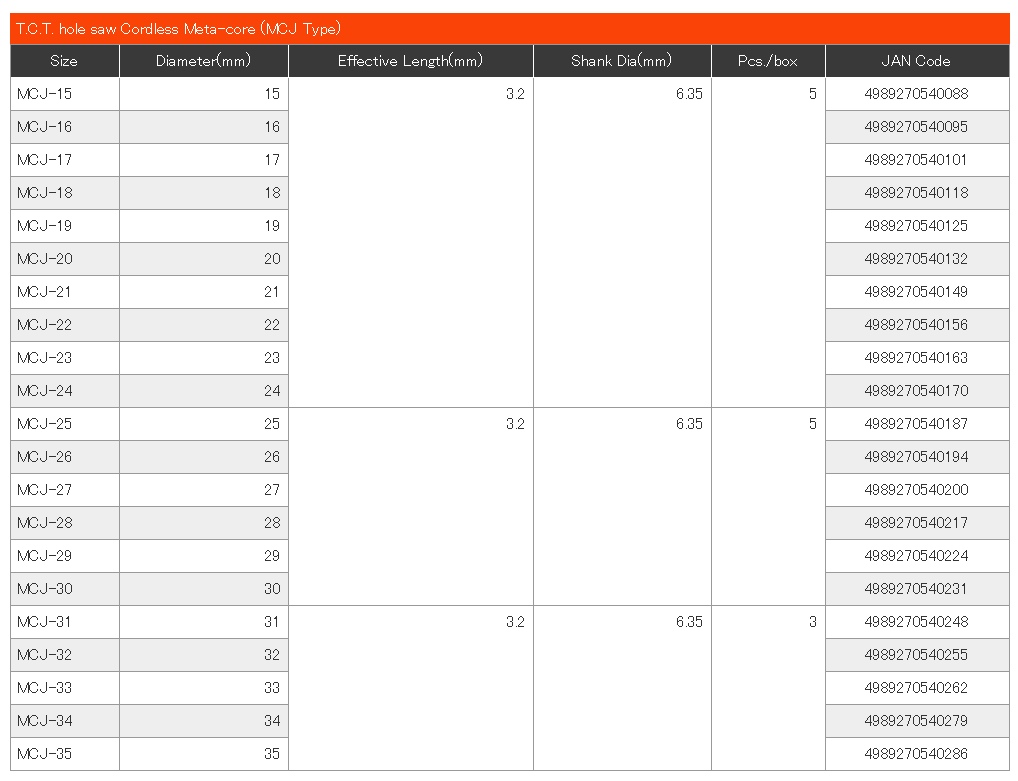

Model: T.C.T. hole saw Cordless Meta-core (MCJ Type)/ Center Drill/ Ejector spring/ Cordless Meta-core (Tool Box Set)

■A first in Japan! T.C.T. hole saw for use with rechargeable and small electric drills (under 400W). Enables drilling of stainless steel with low power.

■Cutting resistance cutting edges and center drills comprehensively reduced. Allow 3 times the number of hole drilling with a full charge (compared with standard Meta-core).

◆Effective length: 3.2mm(Body depth : 5mm)

◆Matching drill: Cordless drill/Electric drill(under 400W)

◇Ejector spring fitted as standard/compatible with stainless steel

USES

Sheet metal• Stainless steel (2mm or less)• Aluminum (2mm or less)• FRP• PVC• Plastic

No Impact

■Materials that can be drilled

- Stainless steel plate (SUS304 equivalent)

- Milled steel plate (SS400, SPCC, SPHC, etc.)

- FRP plate

Compatible Motors

- Rechargeable drills of a rotation speed of approximately 1,000 rpm and rotary torque of 50 N-m (approx. 50 kgf-cm) specifications (for rotation use only).

- Compact electric drills with electric power consumption of 400 W or less.

*Cannot be used with impact wrenches, impact drivers, drilling machines, percussion drills, or hammer drills.

*Use with a rechargeable drill at 9.6V or more.

■Stainless Steel Plate Drilling Data

- Diameter used: 21 mm

- Work material: Stainless steel plate (SUS 304)

- Thickness of work material: t = 1.0 mm

- Rechargeable tool used: 12V rechargeable drill driver (Fast mode)

- Drilling frequency: Approx. 25 times (on a full charge)

- Average drilling time/pc.: Approx.5 sec.

- Drilling available count: Approx. 120 times

-

Cordless driver (9.6V or more)

-

Electric drill (400W or less)

*You cannot use with the percussion drill.

- Use electrical drills appropriate for the hole saw used.

- Be sure to turn off the main switch of the drill and disconnect the power supply plug from the socket before attaching and detaching the hole saw.

- Do not touch the hole saw, the shavings, or the drilled surface by hand because they may be hot by drilling friction.

- Wear working clothes suitable for operation, including eye protection equipment to prevent shavings from getting into eyes.

- Prepare working environment before starting jobs.

- Read carefully the instruction manual for the electrical drill used before use.

SPECIFICATION

T.C.T. hole saw Cordless Meta-core (MCJ Type)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| MCJ-15 | 15 | MCJ-22 | 22 | MCJ-29 | 29 |

| MCJ-16 | 16 | MCJ-23 | 23 | MCJ-30 | 30 |

| MCJ-17 | 17 | MCJ-24 | 24 | MCJ-31 | 31 |

| MCJ-18 | 18 | MCJ-25 | 25 | MCJ-32 | 32 |

| MCJ-19 | 19 | MCJ-26 | 26 | MCJ-33 | 33 |

| MCJ-20 | 20 | MCJ-27 | 27 | MCJ-34 | 34 |

| MCJ-21 | 21 | MCJ-28 | 28 | MCJ-35 | 35 |

Center Drill Ejector spring Cordless Meta-core (Tool Box Set)

| Size | Diameter(mm) | Size | Hole Saw Size(mm) | Size | Set Dia(mm) | ||

| S-4 | 4 | MCJ KS-No.1 | 15-35 | TB-22 | 21 | ||

| TB-23 | 22 | ||||||

| TB-24 | 25 |