Drilling and Cutting, Japan, Unika

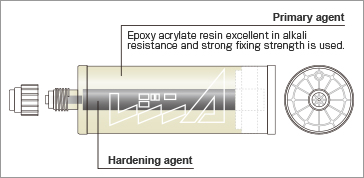

UNIKA GE-410 (Cartridge Type) Resin A

Manufacturer: UNIKA

Model: GE type (Resin cartridge), GE type exclusive parts, Installation specifications, GE-410 TOOL BOX SET, Push pump, Metal brush, Extension nozzle(including three), Plastic sleeve (including 10 pieces)

- ■Can be used for various bolts, sizes and shapes of different reinforced steels.

- ■Used extensively for concrete, brick, stone material and hollow base material.

- ■Demonstrates stable fixing strength because primary material and hardening agent are constantly mixed by mixing nozzle.

- ■Adopts a highly alkali resistant epoxy acrylate resin.

Uses

Concrete•Stone material•Hollow base material•ALC

- Drill vertically to target surface with the determined preparation diameter and preparation hole depth.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Remove chips adhered in the hole using a brush, and use a dust collector or blower to clean in the hole again.

- Insert the nozzle down to the hole bottom and fill resin.

- Insert the bolt down to the hole bottom while slowly turning it by hand.

- Do not move the anchor bolt within the determined hardening time after embedding.

■Uses

Foundation work for iron frame, Passage construction work, Tunnel construction work, Installation for vibrating machines.

■Structural Drawing

| Nominal diameter(mm) |

M8 | M10 | M12 | M16 | M20 | M22 | M24 |

|---|---|---|---|---|---|---|---|

| Preparation hole diameter(mm) |

10.0 | 12.0 | 14.0 | 18.0 | 24.0 | 25.0 | 28.0 |

| Embedment depth(mm) |

80 | 90 | 110 | 130 | 170 | 190 | 210 |

| Required resin amount(ml) |

4 | 6 | 9 | 15 | 42 | 43 | 66 |

| Recommended tightening torque(Nm) |

10 | 20 | 40 | 80 | 120 | 140 | 160 |

| Number of pieces installed(Pcs.) |

92 | 62 | 40 | 25 | 8 | 8 | 5 |

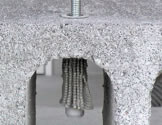

■Installation Example

■Shape of bolt used

Cannot be used for a round bar. Use bolts which have irregularity on a surface such as a continuous thread bolt and different shape bar steel.

■Guideline for hardening time

| Temperature(℃) | -5 | 5 | 15 | 25 | 35 |

|---|---|---|---|---|---|

| Use time(minutes) | 40 | 20 | 9 | 5 | 3 |

| Hardening time(minutes) | 180 | 90 | 60 | 30 | 20 |

(Do not move the anchor reinforcement within the hardening time.)

■Plastic sleeve installation specifications

| Nominal diameter(mm) |

M8 | M10 | M12 |

|---|---|---|---|

| Preparation hole diameter(mm) |

16.0 | 16.0 | 20.0 |

| Matching sleeve(Code) |

RA-P1685 | RA-P1685 | RA-P2085 |

| Required resin amount(ml) |

30 | 30 | 40 |

- Avoid direct sunlight and store in a well-ventilated place where the temperature does not rise so high.

(Never raise the temperature above 40℃. Always keep the temperature in the range of 5 to 25℃.) - Do not bring close to fire or high temperature objects.

- Cartridge can be stored until the expiration date for use under standard storage conditions.

- Wear protective equipment (such as protective glasses and mask) when using.

- When resin adheres to skin, irritation may occur in rare cases. Take action such as immediately wiping and rinsing with a hot soapy solution.

In addition, if resin gets into eyes, immediately rinse with a large amount of water and seek medical attention.

- Make sure to provide the drilling diameter and drilling depth as described in the specifications.

- Make sure to use both a metallic brush and blower to sufficiently clean inside the hole.

- Make sure to mount the mixing nozzle with it just before use.

- Make sure to discard first approximately 20~30cc at a time of first use and nozzle replacement. (Mixing improperly may result in reduction in strength.)

- This cannot be used for a steel bar with no irregularity such as a round bar.

- Refer to the scale on the cartridge label for discharge resin amount.

- Do not move the bar steel nor apply load within the determined hardening time.

- SPECIFICATIONS

-

Size Capacity(ml) GE-410 410

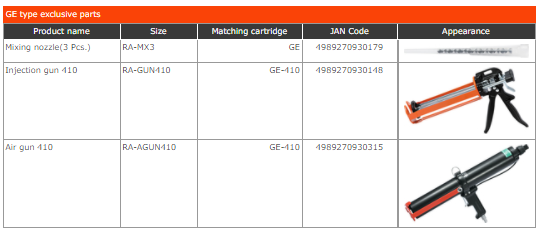

- GE type exclusive parts

-

Product name Size Matching cartridge Mixing nozzle(3 Pcs.) RA-MX3 GE Injection gun 410 RA-GUN410 GE-410 Air gun 410 RA-AGUN410 GE-410

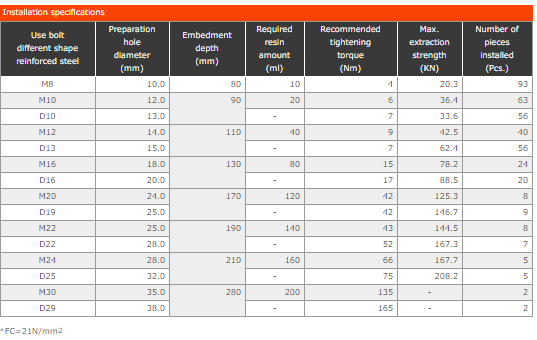

- Installation specifications

-

Use bolt different shape reinforced steel Preparation hole diameter (mm) M8 10 M10 12 D10 13 M12 14 D13 15 M16 18 D16 20 M20 24 D19 25 M22 25 D22 28 M24 28 D25 32 M30 35 D29 38

-

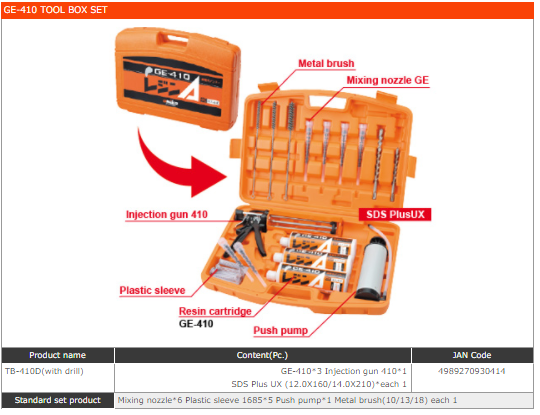

GE-410 TOOL BOX SET

-

Product name Content(Pc.) TB-410D(with drill) GE-410*3 Injection gun 410*1 SDS Plus UX (12.0X160/14.0X210)*each 1 Standard set product Mixing nozzle*6 Plastic sleeve 1685*5 Push pump*1 Metal brush(10/13/18) each 1

-

■Related items

- Push pump

-

Size Specifications RA-PUP (Nozzle diameter) 10mm (Hose length) 270mm

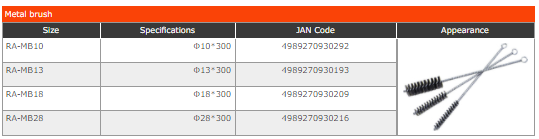

- Metal brush

-

Size Specifications RA-MB10 Φ10*300 RA-MB13 Φ13*300 RA-MB18 Φ18*300 RA-MB28 Φ28*300

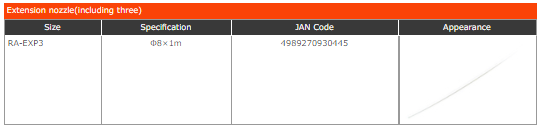

- Extension nozzle(including three)

-

Size Specification RA-EXP3 Φ8×1m

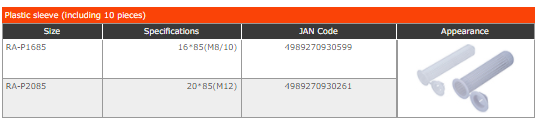

- Plastic sleeve (including 10 pieces)

-

Size Specifications RA-P1685 16*85(M8/10) RA-P2085 20*85(M12)

Related Products

-

Shimizu Chistagane – Hand Tools

-

Hasegawa Electric HLA-1A Voltage Detector Checker (Handy Type)

-

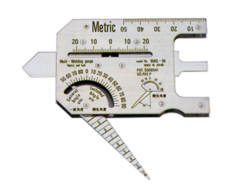

Fuji Tool Welding Gauges

-

Kyowa LMA-A-1KN LMA-A Small-sized Compression Load Cell

-

SAKUSAKU TNMG160404-MF Turning Insert 60° Triangular/Negative

-

Kyowa BER-A-2MP17S BER-A-17S Wall-surface Soil Pressure Transducer