Drilling And Cutting, Japan, Unika

UNIKA UR21 D-Series Dry Diamond UR21-D Short Body

Manufacturer: UNIKA

Model: UR-D (Set)/ UR-D (Body)/ UR-D (Center Pin)/ UR21 (Shank Assembly)/ UR-D (Standard Accessory)

■Capable of drilling reinforced concrete(cutting up to triple-reinforcement), blocks, mortar etc. without the use of water.

■Center pin type cuts using only rotation force, greatly reducing noise and vibration.

◆Applicable Electric Tool: Electric Drill / Percussion Drill (rotating mode)

*For porcelain ceramic tile and stone, water should be used.

USES

REINFORCED CONCRETE•HARD EXTERIOR PANEL•Resin-based ARTIFICIAL MARBLE•MORTAR•

SOFT EXTERIOR PANEL•BLOCK•BRICK•*CERAMIC TILE

PRECAUSION ON USE

- Note that the cutting edge may experience wear sooner when used for concrete without the elapse of an insufficient curing period.

■Make sure to use the drill in the “rotation mode.” Using the drill in the percussion/impact mode may cause reakins of the cutting edge or other failures.

■Note that forced insertion/removal operations during drilling (the cutting edge collides against the hole bottom or hole wall) or excessive tilting of a tool may also cause failures.

■Make sure to use this product in a “dry” condition. Using it in a wet or a damp condition may cause not only a shorter life but also reduced operating efficiency.

■Handling Method (Dry Diamond UR-D/DL [common])

![Handling Method (Dry Diamond UR-D/DL [common])](https://www.unika.co.jp/en/products/ur21/images/ur21d_dg1.gif)

- Align the center pin with the drilling position. Hold it tight and turn on the motor switch. [Rotation mode]

- Stop the motor when the cutting edge is inserted approximately 5 mm and remove the center pin.

- Lightly press the body against the drilling groove and continue operation.

■Dressing (sharpening) operation

Perform dressing (sharpening) operation in the following cases:

■Where cutting quality deteriorates during drilling

■Where burns or discoloration is detected on the cutting edge

In dressing operation, perform normal drilling in heavy weight (hollow) blocks or GC/WA grinding wheels. Dressing operation is completed when diamond particles protrude from the cutting edge surface and streaks in the rotation direction become clear.

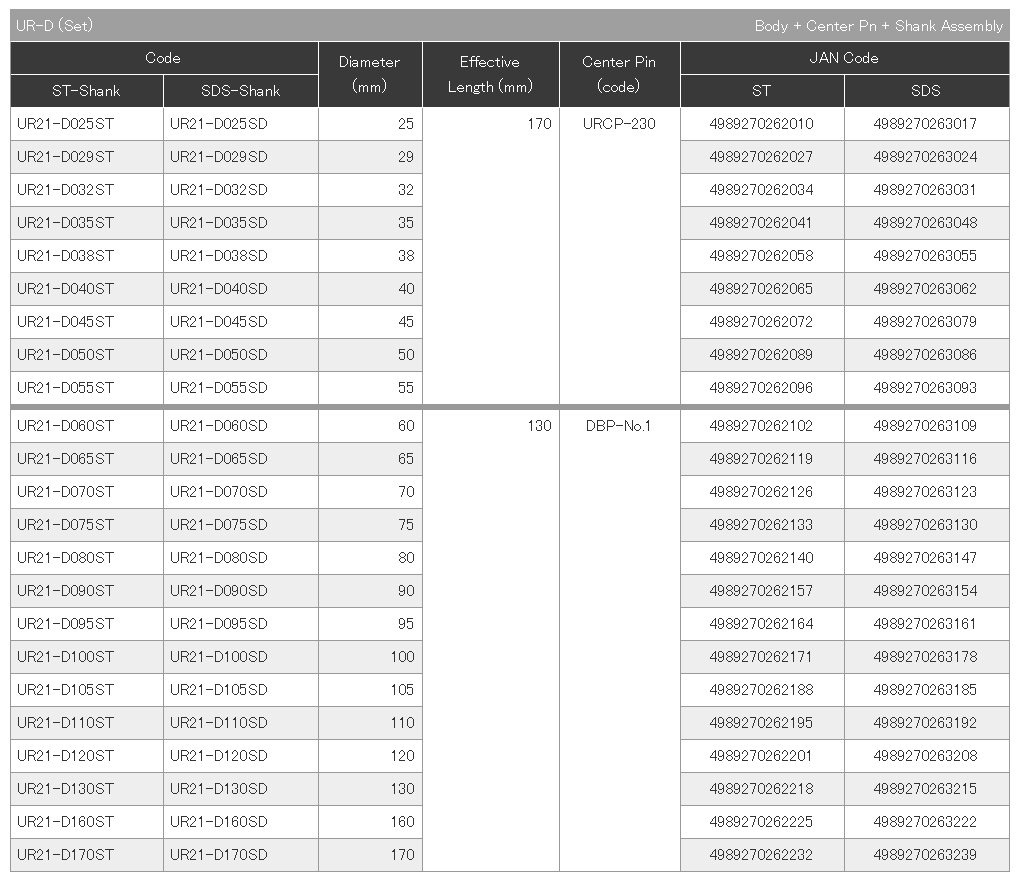

UR-D (Set)

| Code | Diameter (mm) |

Code | Diameter (mm) |

Code | Diameter (mm) |

|||

| ST-Shank | SDS-Shank | ST-Shank | SDS-Shank | ST-Shank | SDS-Shank | |||

| UR21-D025ST | UR21-D025SD | 25 | UR21-D055ST | UR21-D055SD | 55 | UR21-D100ST | UR21-D100SD | 100 |

| UR21-D029ST | UR21-D029SD | 29 | UR21-D060ST | UR21-D060SD | 60 | UR21-D105ST | UR21-D105SD | 105 |

| UR21-D032ST | UR21-D032SD | 32 | UR21-D065ST | UR21-D065SD | 65 | UR21-D110ST | UR21-D110SD | 110 |

| UR21-D035ST | UR21-D035SD | 35 | UR21-D070ST | UR21-D070SD | 70 | UR21-D120ST | UR21-D120SD | 120 |

| UR21-D038ST | UR21-D038SD | 38 | UR21-D075ST | UR21-D075SD | 75 | UR21-D130ST | UR21-D130SD | 130 |

| UR21-D040ST | UR21-D040SD | 40 | UR21-D080ST | UR21-D080SD | 80 | UR21-D160ST | UR21-D160SD | 160 |

| UR21-D045ST | UR21-D045SD | 45 | UR21-D090ST | UR21-D090SD | 90 | UR21-D170ST | UR21-D170SD | 170 |

| UR21-D050ST | UR21-D050SD | 50 | UR21-D095ST | UR21-D095SD | 95 | |||

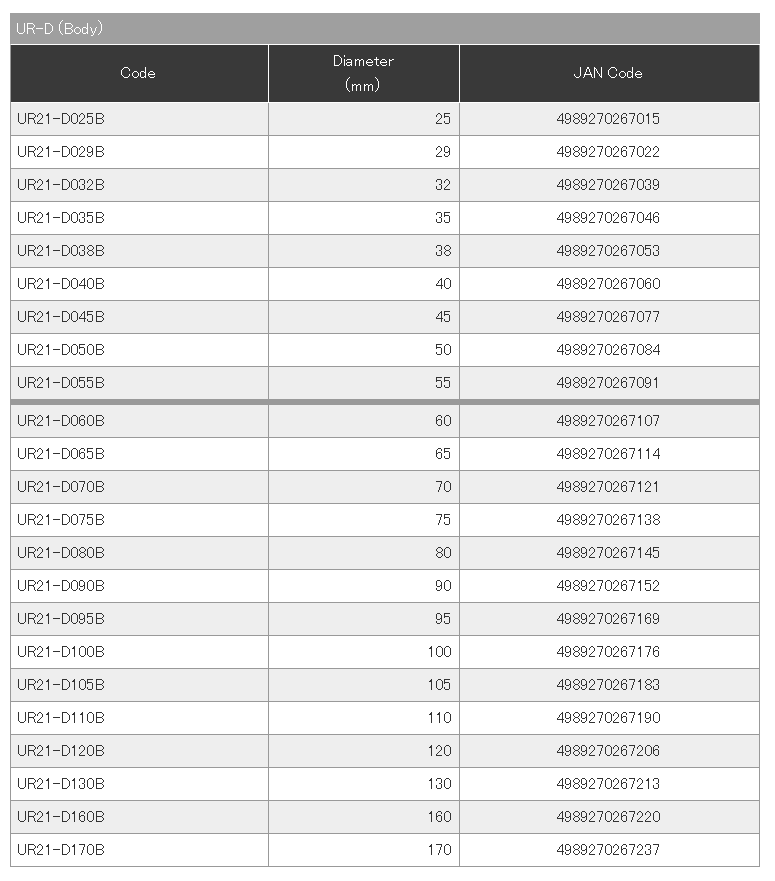

UR-D (Body)

| Code | Diameter (mm) |

Code | Diameter (mm) |

Code | Diameter (mm) |

| UR21-D025B | 25 | UR21-D055B | 55 | UR21-D100B | 100 |

| UR21-D029B | 29 | UR21-D060B | 60 | UR21-D105B | 105 |

| UR21-D032B | 32 | UR21-D065B | 65 | UR21-D110B | 110 |

| UR21-D035B | 35 | UR21-D070B | 70 | UR21-D120B | 120 |

| UR21-D038B | 38 | UR21-D075B | 75 | UR21-D130B | 130 |

| UR21-D040B | 40 | UR21-D080B | 80 | UR21-D160B | 160 |

| UR21-D045B | 45 | UR21-D090B | 90 | UR21-D170B | 170 |

| UR21-D050B | 50 | UR21-D095B | 95 |

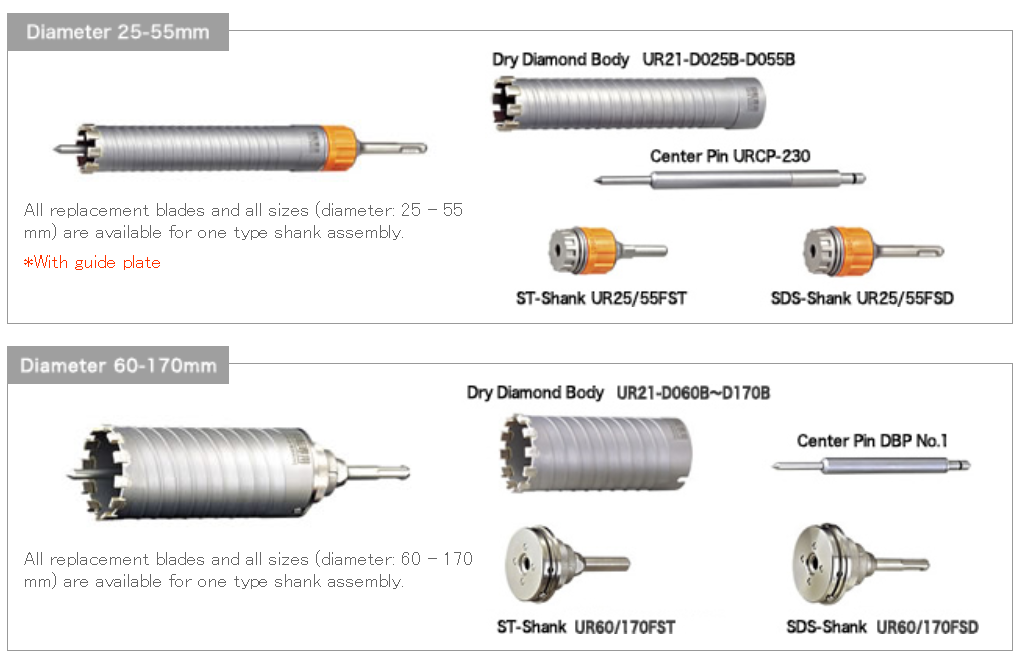

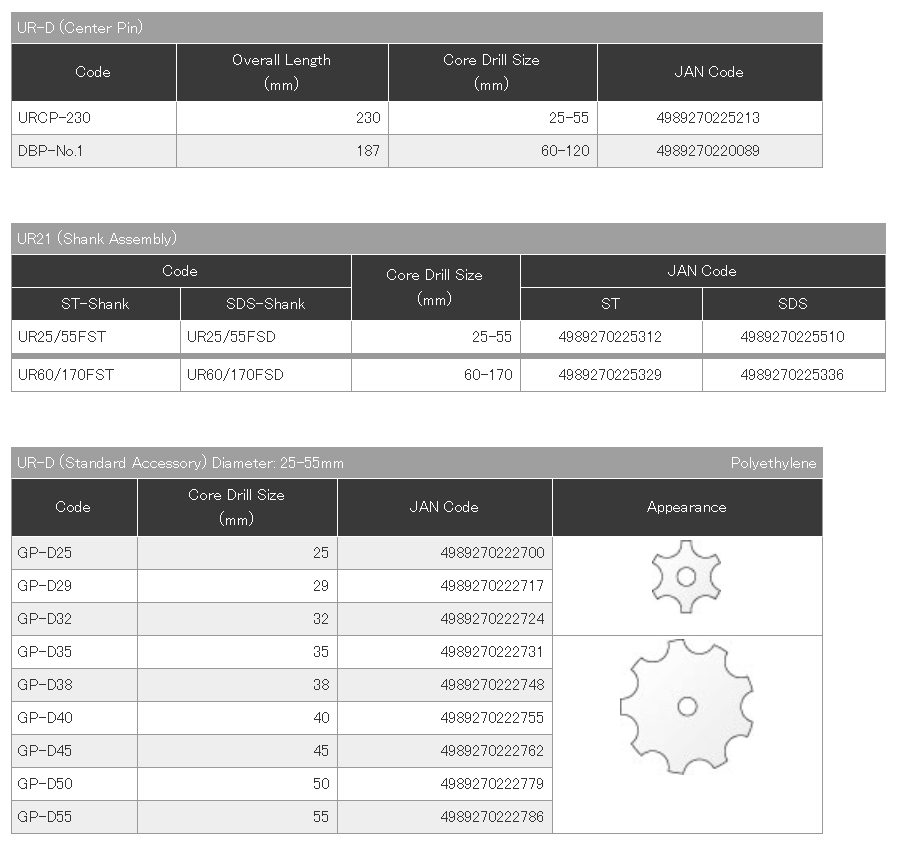

UR-D (Center Pin) UR21 (Shank Assembly)

| Code | Overall Length (mm) |

Code | Core Drill Size (mm) |

||

| ST-Shank | SDS-Shank | ||||

| URCP-230 | 230 | UR25/55FST | UR25/55FSD | 25-55 | |

| DBP-No.1 | 187 | UR60/170FST | UR60/170FSD | 60-170 | |

UR-D (Standard Accessory)

| Code | GP-D25 | GP-D29 | GP-D32 | GP-D35 | GP-D38 | GP-D40 | GP-D45 | GP-D50 | GP-D55 |

| Core Drill Size (mm) | 25 | 29 | 32 | 35 | 38 | 40 | 45 | 50 | 55 |

SPECIFICATION

Related Products

-

Fujii Denko T-2-NV93SV-21KS-BK Harness & Lanyard

-

Nippon Chemical Screw PEEK/NT(Thread size-L) PEEK/inch hex nut

-

TONE SHATK3 Accessory Of Tool Holder (Aluminium Type)

-

TSUBOSAN Triangular Engineer’s Files

-

Vessel No.PD Replacement bit

-

Super Tool APT4040/5050/6363 BS /CS/B/C Angle Plate T-Slot Type (16 and 18) For MC