Yamashina Seiki

Yamashina Seiki FlexLink Conveyor

Product Made In Japan

Manufacture: Yamashina Seiki

Model: FlexLink Conveyor

Component Module

FlexLink conveyor systems consist of plastic chains that can be oriented up, down, left or right, and highly modular standard components to enable straight, horizontal and three-dimensional line layouts.

Space Saving

Compactly designed components allow close layout to equipment. Additionally, the installation space can be kept compact.

Features

- Free layout – 3-dimensional transport –

- Make the most of limited space

- Easy connection to equipment/machines

- Easy layout changes

- low noise

Specifications

| Conveyor type | Beam width | Chain width | Chain pitch | Allowable traction force | Maximum lifting height | Conveyed object width | Transported object weight |

|---|---|---|---|---|---|---|---|

| X45 | 45mm | 43mm | 12.7mm | 200N | 2m | ~200mm | ~250g |

| X65 | 65mm | 63mm | 25.4mm | 1,000N | 8m | ~300mm | ~1,000g |

| X85 | 85mm | 83mm | 33.5mm | 2,000N | 8m | ~300mm | ~2,000g |

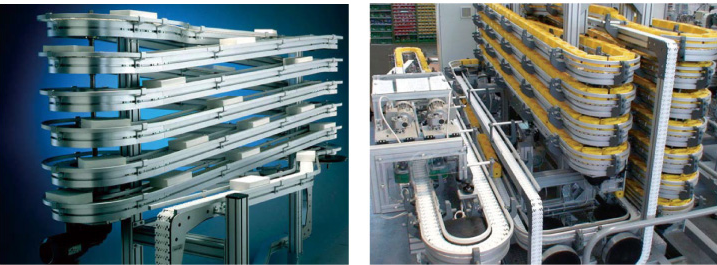

Examples of Various Combinations

- Rising/falling lines in one spiral structure

- Secure vertical storage capacity even in small installation spaces

- Compact design, space-saving buffer

- Paired spiral structure with rising line on one side and falling line on the other.

- Large buffer capacity by securing space in the horizontal direction

- Increase capacity by increasing the number of machines.

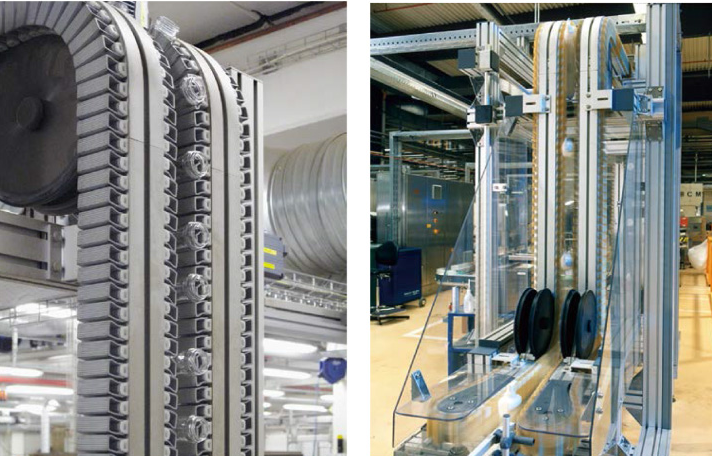

FlexLink wedge conveyors are grip conveyors with two opposing conveyor tracks. High speed and continuous operation provides higher transport capacity and productivity compared to traditional vertical transport/elevating equipment.

Related Products

-

Yamashina Seiki Horizontal CNC Facing Machine with Multi-Function Capabilities for Large Ship Rudder Hole Processing

-

Yamashina Seiki Tabletop R Chamfering Machine Edgenein (Edge Nine)

-

Yamashina Seiki MLDC Type Exhaust Valve Arm Lubricator

-

Yamashina Seiki BT-50 – Horizontal Column Traverse Type Machining Cell for Truck and Bus Front Axle End Machining

-

Yamashina Seiki Tabletop R Chamfering Machine

-

Yamashina Seiki Exhaust Valve Stem Valve Seat Grinding Machine