Japan

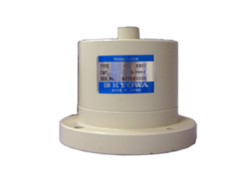

Zetec MIZ-21C Eddy-current Flaw Detector

Made in Japan

Manufacturer: Zetec

Model: ZES-HHT-MIZ-21C-SF/ ZES-HHT-MIZ-21C/ ZES-HHT-MIZ-21C-ARRAY/ ZES-HHT-MIZ-21C-SF_WIRELESS-LOCKED/ ZES-HHT-MIZ-21C_WIRELESS-LOCKED/ ZES-HHT-MIZ-21C-ARRAY_WIRELESS-LOCKED

Feature:

_Ergonomic Design because it is very small and lightweight, it can be used comfortably even in a small place.

_Intuitive touchscreen

_External interface for efficient operation USB, Wi-Fi and Bluetooth are supported.

_Ready for harsh environments The body’ sample operating temperature range and fully sealed design allow it to cope with possible outdoor environments. We also conduct drop and vibration tests that take into account tough specifications.

Applications:

_Inspection for inter-laminate corrosion

_Measurement of conductivity and coating thickness

_Inspection of corrosion and cracks in piping, pressure vessels and tanks

_Evaluation and sizing of cracks in welds with surplus and FSW (friction stirred joints)

Specification:

| Basic Specifications | |

|---|---|

| Dimensions (HxWxD) | 267mm×122mm×38mm |

| Weight (with battery and cover) | 1.2kg |

| Multi-touch display | 5.7 inch 480×640 pixels |

| Battery life | Up to 10 hours |

| Eddy-current probe connector | Lemo18-pin |

| eddy current array probe connector | Lemo26-pin |

| interface | USB2.0, Wi-Fi, Bluetooth |

| encoder | 2 axes (phase contrast output) |

| Maximum number of probe coils | MIZ-21C-SF:2 MIZ-21C:2 MIZ-21C-ARRAY:32 |

| Frequency bandwidth | 5Hz to 10MHz |

| Signal generator output | Up to 12Vpp (ECA 19Vpp), adjustable with 0.1 volt pitch |

| Receive Gain | 10~132dB |

| Data Resolution | 16-bit |

| Probe drive | 50Ω |

| filter | Median, High Pass, Low Pass, High Pass 2 (modulated CC), Band Pass, Spike, SNR |

| Conductivity measurement frequency | 60、120、240、480KHz |

| Conductivity measurement specification | 0.9~110% IACS (0.5~70MS/m) digital readout, accuracy: 0.9%~65%IACS±0.5% IACS in the range of 0.9%~65%IACS, 1.0% in the ±range of more than 65% |

| Non-conductive coating thickness measurement | Non-conductive coating thickness in the range of 0mm~1.000mm can be measured, accuracy: 0.025mm (±0.001″) in the range of 0mm~0.64mm |

| Maximum data size | 60 seconds or 10 meters |

| Built-in drive | 128GB |

| Equipment calibration | ISO/IEC 17025:2005, partially conforming to manufacturer’s requirements |

Product line:

| Model No. | summary |

|---|---|

| ZES-HHT-MIZ-21C-SF | With up to two coil probes with one input and 32 active channels, it is a fully integrated, single-frequency handheld eddy-current inspection system. Supports conductivity measurement. |

| ZES-HHT-MIZ-21C | With up to two coil probes with one input and 64 active channels, this is a fully integrated, dual-frequency handheld eddy-current inspection system. Supports conductivity measurement and rotating probe scanner. |

| ZES-HHT-MIZ-21C-ARRAY | With up to 32 coil probes with three inputs and 192 active channels, it is a fully integrated, dual-frequency handheld eddy-current inspection system. Supports conductivity measurement, rotary probe scanners and surface array probes. |

| ZES-HHT-MIZ-21C-SF_WIRELESS-LOCKED | MIZ-21C-SF without wireless capability |

| ZES-HHT-MIZ-21C_WIRELESS-LOCKED | MIZ-21C without wireless capability |

| ZES-HHT-MIZ-21C-ARRAY_WIRELESS-LOCKED | MIZ-21C-ARRAY not included wireless capability |