Drilling And Cutting, Japan, Unika

UNIKA HC Hammer Core Drill

Manufacturer: UNIKA

Model: HC type (Set)/ HC type (Body)/ HC type (Shank Assembly)/ HC type (Center Pin)/ HC type (Guide Plate)

■Smoothly transmit powerful hammering and rotation force to offer rapid drilling through reinforced concrete(up to 10mm-reinforced).

■Extremely thin body incorporates double spiral to eliminate dispersion of drilling force due to swarf.

■Cope with thick concrete by using shank sizes up to 450mm long.

◆Effective Length: 100mm

◆Matching Drill: Hammer drill

USES

Concrete•Block•Brick

■Handling Procedure

Screw the shank into the core drill body.

*When removing the core body and the shank, place the body facing upward while inserted into the main unit and strike a few times to loosen the round screw.

Insert and set the center pin while aligning it with hole on the tip end of the shank. Attach a guide plate to the set center pin.

Attach to the hammer drill as in the case with the conventional hexagonal shank drill and bull point.

Only the center pin is required for positioning. Pull out the center pin once the work material is drilled to a depth of approximately 5 mm and the drill tip end stops turning, then continue drilling operation.

■Drilling Data

- •Test conditions

- Core diameter used: 55 mm

- Subject material: Concrete (FC = 24.5 MPa)

- Drilling depth: 100 mm

- •Test Results

- Time required for drilling: 5 min.

- Drilling durability count: 100 pcs. or more

- Use electrical drills appropriate for the core drill used.

- Be sure to turn off the main switch of the drill and disconnect the power supply plug from the socket before attaching and detaching the core drills.

- Do not touch the core drill, the shavings, or the drilled hole because they may be hot.

- Wear working clothes suitable for the operation, including eye protection equipment to prevent shavings from getting into your eyes.

- Prepare the working environment before starting jobs.

- Read carefully the instruction manual for the electrical drill used before use.

■Compatible motors

| Manufacturer Name | Model No. | |

|---|---|---|

| Hammer Drill | HITACHI | PR25B |

| DH35 | ||

| PR38E | ||

| PR40SA | ||

| DH40SR | ||

| DH45SA | ||

| DH42 | ||

| Makita | HR3520 | |

| HR3530 | ||

| HR3850 | ||

| HR3811 | ||

| HR4030C | ||

| RYOBI | ED-383N | |

| ED-382NA | ||

| ED-382NP |

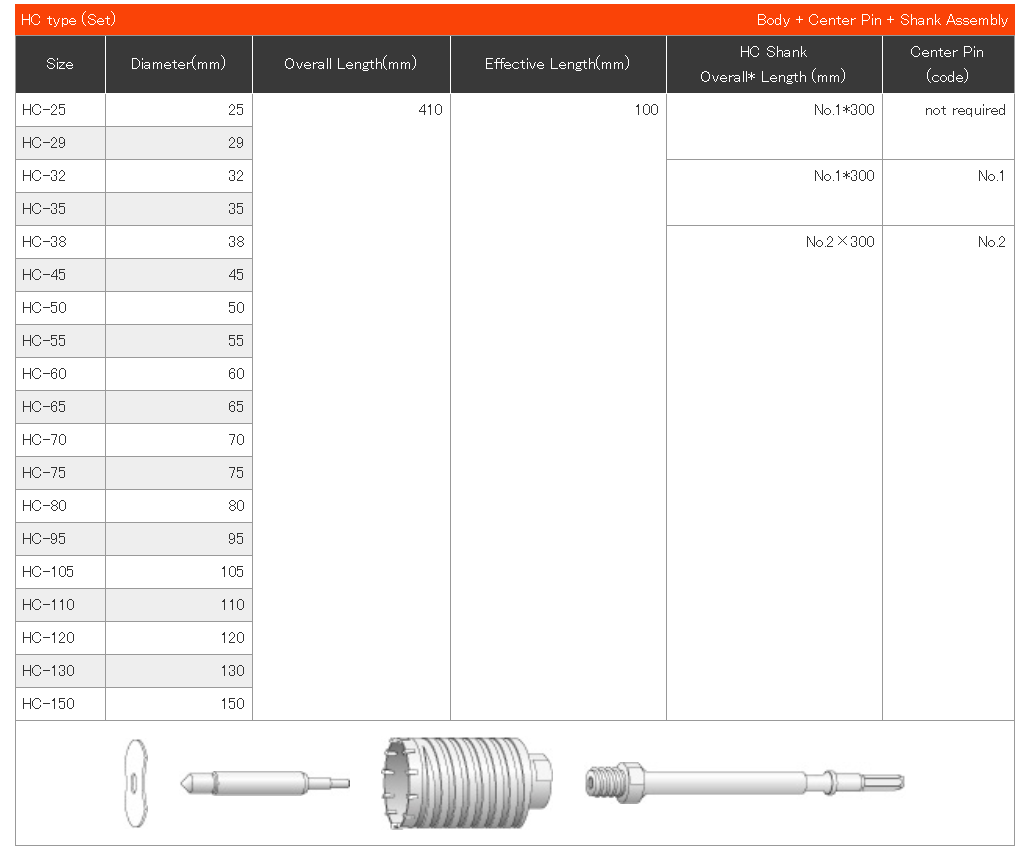

SPECIFICATION

HC type (Set)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| HC-25 | 25 | HC-55 | 55 | HC-105 | 105 |

| HC-29 | 29 | HC-60 | 60 | HC-110 | 110 |

| HC-32 | 32 | HC-65 | 65 | HC-120 | 120 |

| HC-35 | 35 | HC-70 | 70 | HC-130 | 130 |

| HC-38 | 38 | HC-75 | 75 | HC-150 | 150 |

| HC-45 | 45 | HC-80 | 80 | ||

| HC-50 | 50 | HC-95 | 95 |

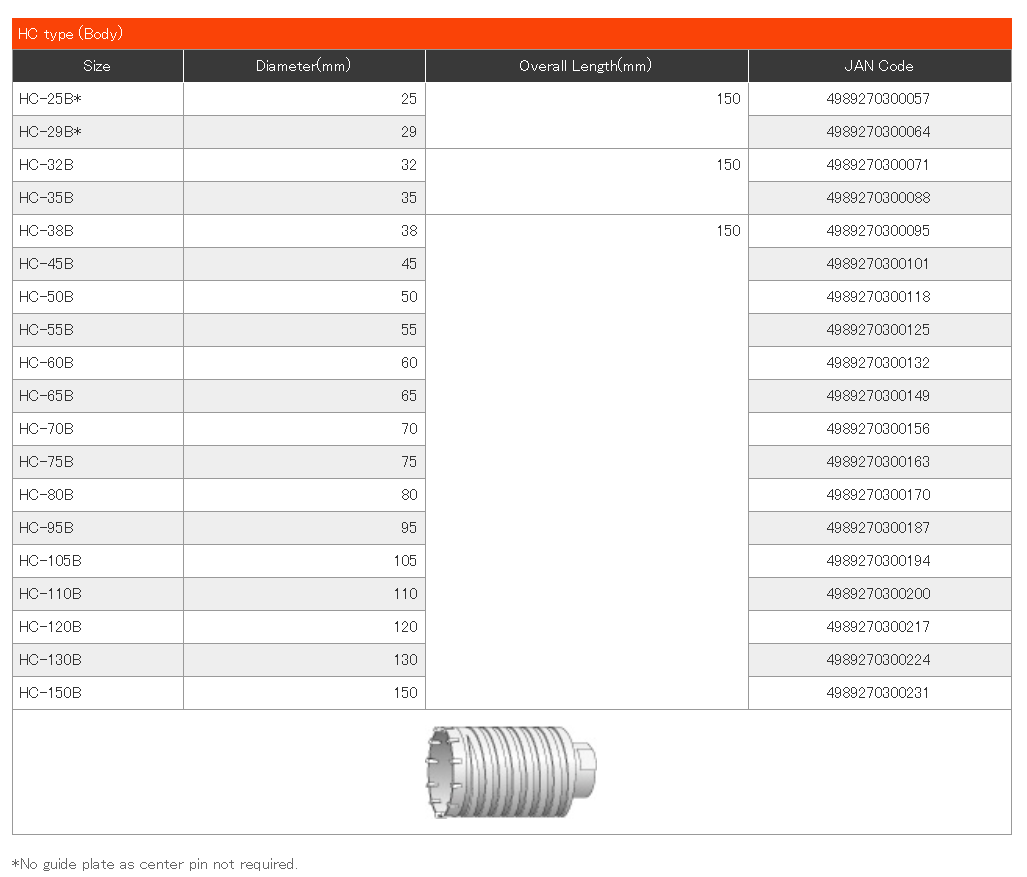

HC Type (Body)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| HC-25B* | 25 | HC-55B | 55 | HC-105B | 105 |

| HC-29B* | 29 | HC-60B | 60 | HC-110B | 110 |

| HC-32B | 32 | HC-65B | 65 | HC-120B | 120 |

| HC-35B | 35 | HC-70B | 70 | HC-130B | 130 |

| HC-38B | 38 | HC-75B | 75 | HC-150B | 150 |

| HC-45B | 45 | HC-80B | 80 | ||

| HC-50B | 50 | HC-95B | 95 |

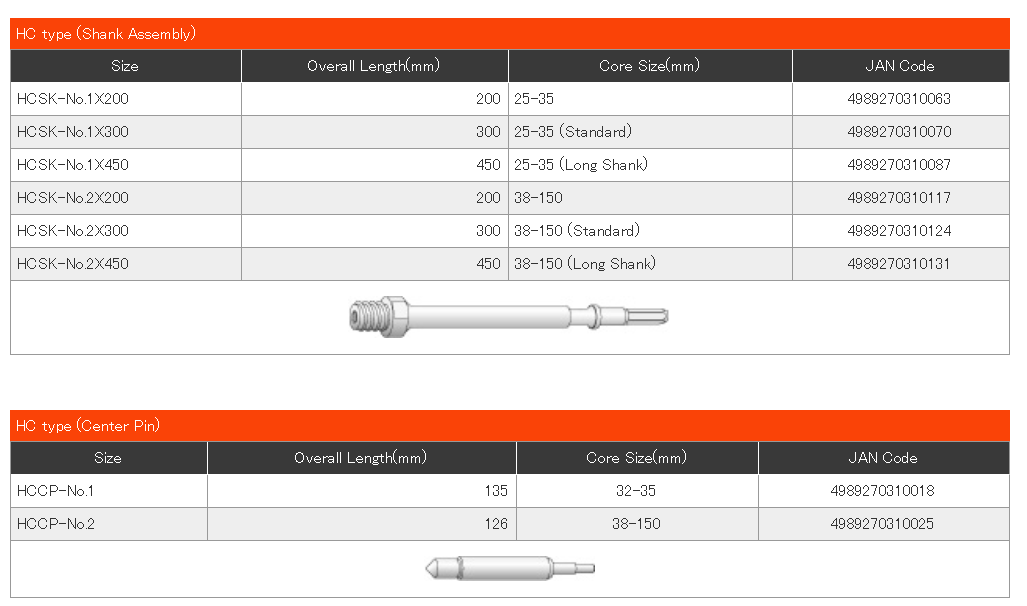

HC type (Shank Assembly) HC type (Center Pin)

| Size | Overall Length(mm) | Size | Overall Length(mm) | |

| HCSK-No.1X200 | 200 | HCCP-No.1 | 135 | |

| HCSK-No.1X300 | 300 | HCCP-No.2 | 126 | |

| HCSK-No.1X450 | 450 | |||

| HCSK-No.2X200 | 200 | |||

| HCSK-No.2X300 | 300 | |||

| HCSK-No.2X450 | 450 |

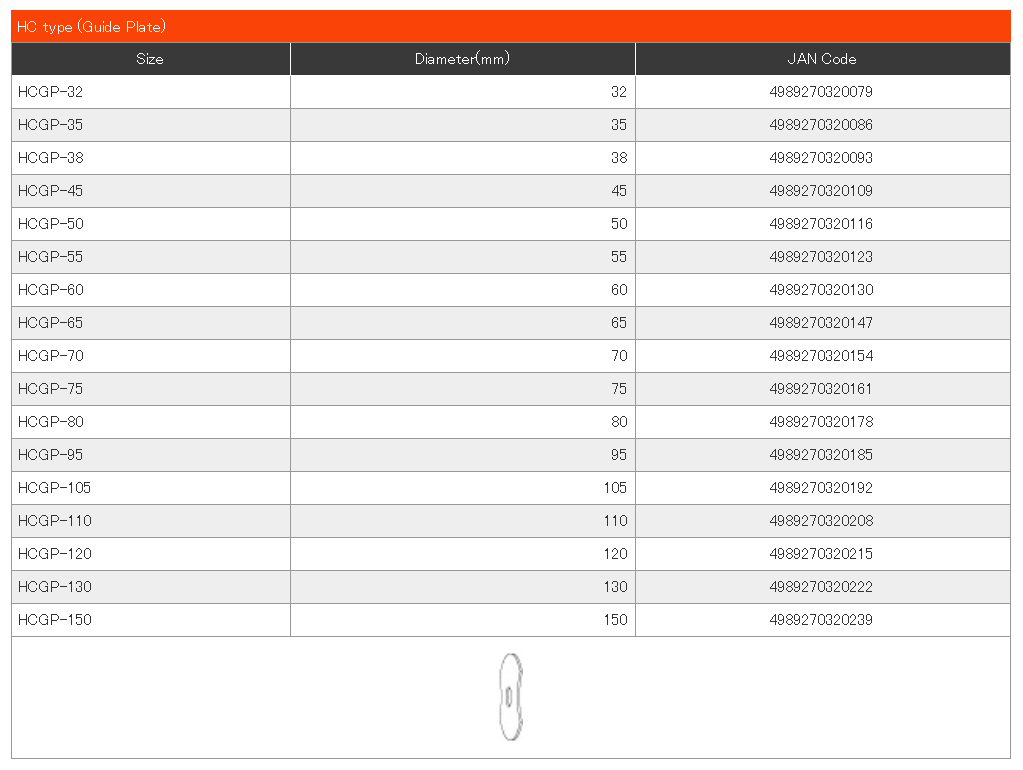

HC Type (Guide Plate)

| Size | Diameter(mm) | Size | Diameter(mm) |

| HCGP-32 | 32 | HCGP-75 | 75 |

| HCGP-35 | 35 | HCGP-80 | 80 |

| HCGP-38 | 38 | HCGP-95 | 95 |

| HCGP-45 | 45 | HCGP-105 | 105 |

| HCGP-50 | 50 | HCGP-110 | 110 |

| HCGP-55 | 55 | HCGP-120 | 120 |

| HCGP-60 | 60 | HCGP-130 | 130 |

| HCGP-65 | 65 | HCGP-150 | 150 |

| HCGP-70 | 70 |