Drilling And Cutting, Hand Tools, Japan, Miyakawa

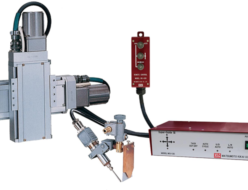

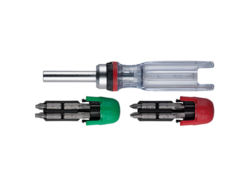

Miyakawa K Type Multi-axis Drill

Product Made in Japan

Manufacturer: Miyakawa

Model: K type

K type

| Features

|  |

|

K type model introduction

| Multi-axis Attachment Model of K Type | Body outer diameter size (φ mm) | Pitch between 2 axes (mm) | Types and names of chucks | |

| K-50 |  | 100 | 8.5-55 | C-3,C-4,C-6,C-10 |

| K-60 |  | 110 | 10-65 | C-4,C-6,C-10 |

| K-70 |  | 130 | 10-73 | C-4,C-6,C-10 |

| K-90 |  | 160 | 10-98 | C-4,C-6,C-10,JT-1,JT-2,MT-1 |

| K-120 |  | 200 | 15-133 | C-6,C-10,C-13,JT-1,JT-2,MT-1 |

| K-140 |  | 230 | 15-153 | C-6,C-10,C-13,JT-1,JT-2,MT-1,MT-2 |

| K-160 |  | 250 | 15-173 | C-6,C-10,C-13,MT-1,MT-2,MT-3 |

| K-190 |  | 280 | 15-203 | C-6,C-10,C-13,MT-1,MT-2,MT-3 |

| K-220 |  | 320 | 15-233 | C-6,C-10,C-13,MT-1,MT-2,MT-3 |

| K-260 |  | 360 | 31-268 | C-10, C-13, MT-1, MT-2, MT-3 |

| K-300 |  | 400 | 31-308 | C-10, C-13, MT-1, MT-2, MT-3 |

| K-360 |  | 460 | 36-360 | C-13, MT-1, MT-2, MT-3 |

| K-400 |  | 500 | 36-400 | C-10, C-13, MT-1, MT-2, MT-3 |

Dimensional drawing of K type

| ability | L1 | L2 | L3 | ||||||

| C-4 | C-6 | C-10 | C-13 | JT-1 | JT-2 | MT-1 | MT-2 | MT-3 | |

| J For 13 mm | 144.5 | 140.5 | 156.5 | 196 | 126.5 | 152 | 219 | – | – |

| For 2M 19 mm | 141.5 | 137.5 | 153.5 | 193 | 123.5 | 149 | 216 | 232 | – |

| For 3M 32 mm | 160.5 | 156.5 | 172.5 | 222 | 142.5 | 178 | 245 | 261 | 321 |

| For 4M 40 mm | 141.5 | 137.5 | 153.5 | 193 | 123.5 | 149 | 216 | 232 | 292 |

| For 5M 60 mm | 166.5 | 162.5 | 178.5 | 218 | 148.5 | 174 | 241 | 257 | 317 |

K type ears (with bracket)

|

|  |

Fixed type K with ears (with bracket)

Dimension table

| Model | Dimensions (mm) |  | ||

| φD | S | φG | ||

| K-50 with ear | 100 | 140 | 20 | |

| K-60 with ears | 110 | 150 | 20 | |

| K-70 with ears | 130 | 170 | 20 | |

| K-90 with ears | 160 | 210 | twenty five | |

| K-120 With ears | 200 | 260 | twenty five |  |

| K-140 with ears | 230 | 290 | twenty five | |

| K-160 with ears | 250 | 320 | 30 | |

| K-190 With ears | 280 | 350 | 30 | |

| K-220 With ears | 320 | 390 | 35 | |

| K-260 With ears | 360 | 430 | 35 | |

| With K-300 ear | 400 | 470 | 35 | |

| K-360 With ears | 460 | 540 | 40 | |

| With K-400 ear | 500 | 580 | 40 | |

Fixed type multi-axis attachment exchange type

| KE type (One hand clamp system) Simply rotate the lever slightly to perform positioning and clamping simultaneously |

| KK type (catching grip type) Tighten with positioning pin with 2 or 4 combination catching grips. |

| KK type (toggle clamp type) Especially when there is weight, if the processing position and posture are horizontal type, draw a multi-axis attachment with a powerful toggle clamp to prevent the drooping. |

K-type performance official

| Type | Outer dimension of multi-axis head (φ mm) | Types and names ofchucks | Maximum shaft center range (mm) that can be drilled | Minimum axial center range (mm) that can be drilled | Drilling capacityper axis (S45C) (mm) | Screw standing capacityper axis (S45C) (M) | Maximum grip diameter of chuck (mm) | Weight with 4 axes (kg) |

| K-50 | 100 | C-3 | 55 | 8.5 | 2 | 2 | 3 | 3.7 |

| C-4 | 10 | 2 | 2 | 4 | 3.8 | |||

| C-6 | 15 | 4 | 4 | 6 | 4.0 | |||

| C-10 | 23 | 6 | 6 | 10 | 4.5 | |||

| K-60 | 110 | C-4 | 65 | 10 | 2 | 2 | 4 | 4.3 |

| C-6 | 15 | 4 | 4 | 6 | 4.5 | |||

| C-10 | 60 | 23 | 6 | 6 | 10 | 5.5 | ||

| K-70 | 130 | C-4 | 73 | 10 | 3 | 3 | 4 | 5.3 |

| C-6 | 15 | 5 | 5 | 6 | 5.4 | |||

| C-10 | 68 | 23 | 7 | 6 | 10 | 6.4 | ||

| MT-1 | 31 | 8 | 6 | 14 | 12.4 | |||

| K-90 | 160 | C-4 | 98 | 10 | 3 | 3 | 4 | 8.1 |

| C-6 | 15 | 5 | 5 | 6 | 8.2 | |||

| C-10 | 93 | 23 | 8 | 6 | 10 | 9.2 | ||

| JT-1 | 37.5 | 5 | 5 | 6.5 | 8.4 | |||

| JT-2 | 45.5 | 8 | 6 | 10 | 9.2 | |||

| MT-1 | 31 | 10 | 8 | 14 | 13.9 | |||

| K-120 | 200 | C-6 | 133 | 15 | 5 | 5 | 6 | 12.2 |

| C-10 | 128 | 23 | 8 | 6 | 10 | 13.2 | ||

| C-13 | 115 | 36 | 1 | 8 | 13 | 14.6 | ||

| JT-1 | 128 | 37.5 | 6 | 5 | 6.5 | 12.4 | ||

| JT-2 | 45.5 | 8 | 6 | 10 | 13.2 | |||

| MT-1 | 115 | 36 | 13 | 12 | 14 | 19.0 | ||

| K-140 | 230 | C-6 | 153 | 15 | 5 | 5 | 6 | 16.0 |

| C-10 | 148 | 23 | 8 | 6 | 10 | 17.2 | ||

| C-13 | 140 | 36 | 10 | 10 | 13 | 19.6 | ||

| JT-1 | 140 | 37.5 | 6 | 5 | 6.5 | 16.2 | ||

| JT-2 | 45.5 | 8 | 6 | 10 | 17.0 | |||

| MT-1 | 140 | 36 | 13 | 12 | 14 | 21.7 | ||

| MT-2 | 130 | 48 | 22 | 16 | 23 | 26.1 | ||

| K-160 | 250 | C-6 | 173 | 15 | 5 | 5 | 6 | 18.7 |

| C-10 | 168 | 23 | 8 | 6 | 10 | 19.7 | ||

| C-13 | 160 | 36 | 10 | 10 | 13 | 21.1 | ||

| MT-1 | 13 | 12 | 14 | 23.5 | ||||

| MT-2 | 150 | 48 | 22 | 16 | 23 | 29.8 | ||

| MT-3 | 140 | 56 | 30 | 22 | 32 | 32.0 | ||

| K-190 | 280 | C-6 | 203 | 15 | 5 | 5 | 6 | 22.5 |

| C-10 | 198 | 23 | 8 | 6 | 10 | 23.5 | ||

| C-13 | 190 | 36 | 10 | 10 | 13 | 24.9 | ||

| MT-1 | 13 | 12 | 14 | 32.1 | ||||

| MT-2 | 180 | 48 | 22 | 16 | 23 | 34.8 | ||

| MT-3 | 170 | 56 | 30 | 22 | 32 | 36.5 | ||

| K-220 | 320 | C-6 | 233 | 15 | 5 | 5 | 6 | 24.6 |

| C-10 | 228 | 23 | 8 | 6 | 10 | 29.3 | ||

| C-13 | 220 | 36 | 10 | 10 | 13 | 35.1 | ||

| MT-1 | 13 | 12 | 14 | 36.7 | ||||

| MT-2 | 210 | 48 | 22 | 16 | 23 | 38.7 | ||

| MT-3 | 200 | 56 | 30 | 22 | 32 | 43.8 | ||

| K-260 | 360 | C-10 | 268 | 23 | 8 | 6 | 10 | 27.5 |

| C-13 | 260 | 36 | 10 | 10 | 13 | 37.3 | ||

| MT-1 | 13 | 12 | 14 | 40.0 | ||||

| MT-2 | 250 | 48 | 22 | 16 | 23 | 43.3 | ||

| MT-3 | 240 | 56 | 30 | 22 | 32 | 52.8 | ||

| K-300 | 400 | C-10 | 308 | 23 | 8 | 6 | 10 | 32.8 |

| C-13 | 300 | 36 | 10 | 10 | 13 | 46.6 | ||

| MT-1 | 13 | 12 | 14 | 47.2 | ||||

| MT-2 | 290 | 48 | 22 | 16 | 23 | 50.7 | ||

| MT-3 | 280 | 56 | 30 | 22 | 32 | 61.9 | ||

| K-360 | 460 | C-13 | 360 | 36 | 10 | 10 | 13 | 58.6 |

| MT-1 | 13 | 12 | 14 | 59.5 | ||||

| MT-2 | 350 | 48 | 22 | 16 | 23 | 63.4 | ||

| MT-3 | 340 | 56 | 30 | 22 | 32 | 77.4 | ||

| K-400 | 500 | C-13 | 400 | 36 | 10 | 10 | 13 | 68.2 |

| MT-1 | 13 | 12 | 14 | 68.9 | ||||

| MT-2 | 390 | 48 | 22 | 16 | 23 | 73.3 | ||

| MT-3 | 380 | 56 | 30 | 22 | 32 | 89.9 |

Related Products

-

DIJET TLZD Type Modular Head Spot Facing Drill

-

Watanabe WKM-PXR□N Power multimeter (demand/harmonic measurement)

-

Matsumoto Kikai WSG-1300/2300 Automatic Groove Tracking Device “Super Guide”

-

Vessel No.TD-6804MG Ratchet Screwdriver

-

U_RD CTL-24-S28-20Z AC Current Sensor

-

BIX 3/8″-1/2″ Square Drive Antivibration Socket With Ring Magnet