Dia Electronics Application, Japan

Automatic Ultrasonic Flaw Detector For Sintered Parts

Made in Japan

Manufacturer: Dia Electronics Application

Model: SCAN-M4

Feature:

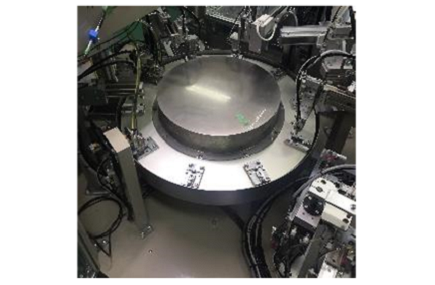

This equipment performs 100% inspection for cracks in sintered parts used in automobile parts, etc., using ultrasonic flaw detection.

Since minute cracks are detected and inspected using rust preventive oil, there is no need to worry about rust.

In addition, the combination of parts feeder and index table demonstrates high processing performance.

Specifications:

1) Target work

・Shape: Any Small parts

・Material: Fe-based sintered product

・Dimensions, etc.: 50 mm or less

2) Flaw detection method and inspection performance

・Flaw detection method: Local oil immersion vertical flaw detection method

・Target flaws: Corner cracks, etc.

・Inspection performance: depth 0.3mm x length 2mm slit

・Processing capacity: 3 to 5 seconds/piece or less