Fukudaco, Japan

Fukudaco Sentinel® Floating Brush Seal | High-Performance Seals

Manufacturer: Fukudaco

Overview

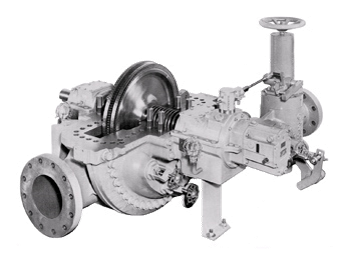

Protects the carbon rings of industrial steam turbines, prevents steam leakage, and avoids bearing damage and lubricant degradation.

Applications

- Industrial steam turbines

- Extending the life of carbon rings

- Preventing steam leakage and steam loss

Features

- Hybrid seal combining carbon rings and brush seals

- Lightweight design prevents steam leakage while adapting to turbine shaft movements

- Replace half of the carbon rings with FBS, ensuring long-term steam leakage prevention

Industrial Steam Turbine Challenges

Steam leaks occur

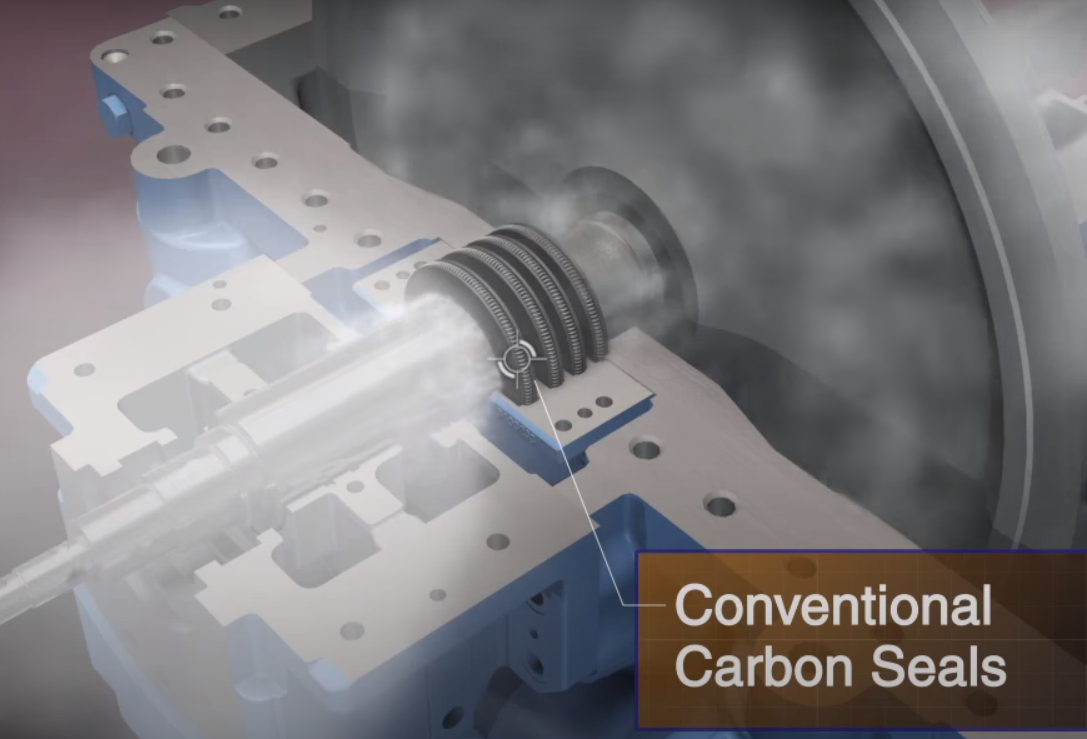

Historically, steam seals such as carbon rings were designed to fit tightly around the shaft.

Due to the tight clearance with the shaft, these carbon rings tend to be fragile and prone to early wear. Carbon seals are also susceptible to damage and cracking from poor-quality steam.

As carbon seals deteriorate, the clearance with the shaft increases, leading to steam leakage, equipment downtime, and increased maintenance costs.

When steam leaks occur from the standard carbon ring seals in steam turbines, the leaked steam can enter the bearing housing, causing premature bearing damage and wasting valuable steam.

Traditional Carbon Rings

- Fragile and prone to wear

- A short lifespan (3–12 months) compared to the required lifespan of 3–5 years or until the next maintenance

- Poor performance under pressure and high peripheral speed (approximately 40 psi per ring and 50 m/s peripheral speed)

- Fluid adhesion phenomenon: Requires 15 minutes to 1 hour of low-speed run-in

- Steam leakage leads to lubricant degradation by entering the bearings

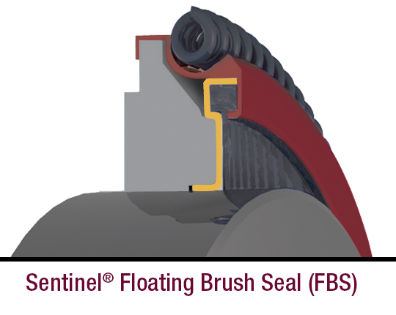

Sentinel® Floating Brush Seal (FBS)

The Sentinel® Floating Brush Seal (FBS) protects carbon rings and delays wear, maintaining effective sealing over an extended period. Field tests have shown that installing Sentinel® FBS on both the high-pressure (upstream) and low-pressure (downstream) sides of carbon rings can extend their lifespan and reduce downtime costs by more than three times.

The Floating Brush Seal is resistant to poor-quality steam, thereby protecting the carbon seals. While typical carbon rings need to be replaced at least once a year, combining them with FBS improves the maintenance cycle to over four years.

The lightweight design of the Sentinel® FBS minimizes shaft wear and heat generation. During installation, the brush rigidity ensures automatic alignment, eliminating the need for complex positioning between the FBS and the shaft. The Sentinel® FBS can be easily installed on-site thanks to the drop-in mechanism for carbon rings.

Related Products

REQUEST QUOTATION

PAYMENT

MAKER

TOOLS & EQUIPMENT

Lifting

Eagle Clamp | Eagle Jack | Elephant | Endo Kogyo

Kanetec | Jung | KITO

Kondotec | Miki Netsuren | Sanei Seiki

Hand Tools

Bix | Miyakawa | Nakatani Kikai | Ogura |

Super Tool | TONE | Yutani

Tape

Kamoi | Kikusui | Nirei | Teraoka

Measurement

Hasegawa | Kawaki | Kett | KGK | Line Seiki | Nagano Keiki

Niigata Seiki | Obishi Keiki | RSK | Ryoden Shonan | Sanko

Showa Seisakusho | Showa Sokki

Safety Tools

Fujii Denko | Shigematsu | Titan

Welding

Asahi Weldex | Daihen | Koike | Nissan Tanaka

Other Tools

Hammer Caster | Matsuda Seiki | Sanritsu

Sanyutec | Toyo Kensetsu Kohki

Yamari

PLANT FACILITIES

Facilities

Acokk | Bunkaboeki | Horiuchi | Konan | Murakoshi

Murakoshi Industries | Nesstech | Nikkin Flux

NFK | Organo | Taiyo Parker

Pump

Honda Kiko | Kyowa | Musashino

Valve

Astam | Kyowa Iron | Nachi | Nippon Daiya | Sawada

Wasino Kiki | Yoshitake

Electricity

Asahi Bagnal | Kokosha | U_RD

CONSTRUCTION

Concrete Work

EXEN | Japan Life | Mikasa | Taiheiyo

High Tension Bolt

Dong Ah | KPF | Nippon Fastener

Bolt & Nut & Washer

Hard Lock | Mori Kozai

Nakaumi | Otani | Toneji

STEEL MATERIAL

Steel & other Material

Dongil | JIS Standard | DSR | Winoa IKK