Chemical, Isolite Insulating, Japan

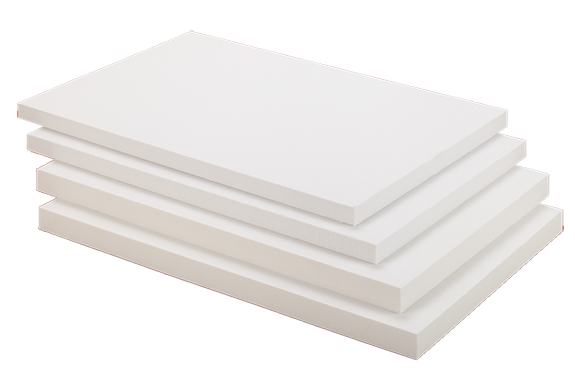

Isolite Insulating Isowool Board

Manufacturer: Isolite Insulating

ISOWOOL BOARD

Features

High-temperature insulating boards vacuum formed using ISOWOOL bulk fiber, organic and inorganic binders

ISOWOOL BOARD is high-temperature insulating boards vacuum formed using ISOWOOL bulk fiber, organic and inorganic binders.

This product will be able to available in rapid heating rapid cooling condition by “suppressing against intensity changes in high-temperature”, “lightweight” and “excellent heat impulsivity”.

Also it has high mechanical strength as compared with other insulation materials.

It can be used for hot face expose lining and backup lining for various furnaces.

Typical Application

Hot-face expose and back-up lining of industrial furnaces.

Quality

| ISOWOOL | 1000 BOARD | 1260 BOARD | 1400 BOARD | H BOARD LT | H BOARD MT | H BOARD HT | H BOARD HMT | |

| Max. Service Temperature(℃) | 1000 | 1260 | 1400 | 1000 | 1100 | 1400 | 1400 | |

| Bulk Density (kg/m³) | 250 | 250 | 250 | 1250 | 1250 | 1150 | 1700 | |

| Loss on Ignition (%) | 6 | 6 | 4 | 1.5 | 1.5 | 1.5 | 3 | |

| Linear Shrinkage (%) at( ℃) × 24hrs | 2.0 (1000℃) | 2.5 (1200℃) | 2.4 (1400℃) | 1.4 (900℃) | 1.4 (1000℃) | 0.6 (1200℃) | 3.4 (1200℃) | |

Thermal Conductivity (W/(m・K)) JIS A1412-1 ※Calculation value | at 400℃ | 0.1 | – | – | 0.18 | 0.18 | – | – |

| at 600℃ | 0.16 | 0.12 | 0.12 | 0.21 | 0.2 | 0.23 | 0.34 | |

| ※at 800℃ | 0.24 | 0.16 | 0.16 | 0.24 | 0.22 | 0.26 | 0.37 | |

| ※at 1000℃ | - | 0.23 | 0.23 | – | – | 0.27 | 0.38 | |

SI BOARD

SI-BOARD is high performance heat insulation material as compared with 1260 BOARD.

Also, it is excellent in bending strength and spalling resistance as compared with conventional product.

ECOBOARD ZERO

This product do not issue forth smoke by production method without organic binders.

Also, it is excellent workability with hardness of internal and external surface are even.

SI BOARD, ECOBOARD ZERO Quality

| 1260 SI BOARD | ECOBOARD ZERO | ||

| Max. Service Temperature(℃) | 1260 | 1200 | |

| Bulk Density (kg/m³) | 190 | 330 | |

| Modulus of Rupture(MPa) | 1.0 | 0.49 | |

| Loss on Ignition (%) | 5 | 0.6* | |

| Linear Shrinkage (%) 1200℃X24hrs | 2.5 | 2.6 | |

| Thermal Conductivity (W/(m・K)) JIS A1412-1 ※Calculation value | at 600℃ | 0.07 | 0.13 |

| ※at 800℃ | 0.1 | 0.16 | |

| ※at 1,000℃ | 0.13 | 0.19 | |

| Chemical Composition(%) | Al₂O₃ | 44 | – |

| Al₂O₃+SiO₂ | 98 | 99 | |

| Hardness (Rubber hardness tester C type, SRIS 0101) | – | 60 | |

* Water of crystallization

Standard Size (mm)

| Thickness | Width | Length |

| 25,50 | 600 | 900 |

Packaging

| Size(mm) | Q’ty per carton | Carton | ||

| Thickness | Width | Length | Size | |

| 25 | 600 | 900 | 4 | 950X640X120 |

| 50 | 600 | 900 | 2 | |