Japan, Kurimoto

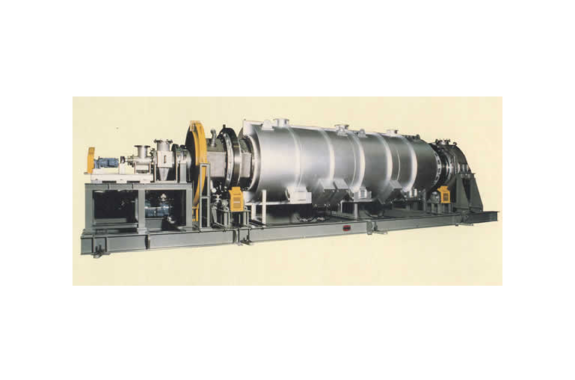

Kurimoto Continuous External Heating Type Rotary Kiln

Product Made in Japan

Manufacturer: KURIMOTO

This machine is an indirect heating type of rotary kiln using electricity, heavy oil, or gas as the heat source. The shell, due to its equilateral hexagonal cross section, minimizes the “shear” of the material layer to provide a sharp distribution of residence time, enabling you to get stable and high quality products of uneven firing.

Features

Equilateral hexagonal shell employed (Refer to Figure-1.)

Compared to cylindrical shell, this shall provides less “shear” of the material layer, a sharp distribution of residence time, and less uneven calcining, increasing the material holding ratio to make the equipment compact in size.

(Figure-1 Comparison of kiln action)

Introduction of superb air sealing performance and special sealing construction enables sealing up to a maximum of pressure of kiln internal pressure±500Pa.

Besides oxidized (i.e., in the air) or neutral (i.e., nitrogen gas or carbon dioxide gas) gas, reducing gas can be used.

Carrier gas or reaction gas can be charged thanks to the improved sealing performance.

Severe calcining temperature control enabled

The calcining temperature is directly measured with sheathed thermocouples inserted in the material layer.

Introducing the multi-chamber type of electric furnace enables independent temperature control of each chamber.

The material temperature is selectable up to a maximum of 1000ºC. Furthermore, if you use gas or heavy oil as the heat source, please introduce the hot air circulation system for energy savings.

Easy settings of residence time

The shell speed varies with the use of the variable speed motor (10:1). Furthermore, variable inclination system is also available for the shell.

Easy installation

The retort, heating oven, and feeder are set up on the common platform, facilitating the installation work. Small-sized kilns come with casters (wheels) for relocation use.

Application

Operation

Drying, pre-calcining, high temperature reaction, and heat treatment

Superb air-tightness enables application to the high temperature reaction process of various kinds of powders in an acid, neutral, or reducing atmosphere.

Heating temperature and material of shell (retort)

300ºC to 1200ºC

Various kinds of stainless steel, Inconel, hastelloy, or heat resisting cast iron (Kurimoto Thermalloy) is used for the shell with consideration given to resistance to heat and corrosion.

Heat source

Electricity (standard), gas, or heavy oil

Objects

The rotary kiln is available for the processing of fine chemical materials up to micron order in size including pigments, ferrite, active carbon, carbon black, various kinds of ceramic materials, powder and particles such as industrial chemicals, and pellets.

Specifications

| Type | Capacity (kg/h) | D(mm) | L0(mm) | L1(mm) | L2(mm) | H(mm) | Drive motor |

|---|---|---|---|---|---|---|---|

| IRK-02 | 7 | 250 | 3700 | 3200 | 1800 | 1450 | 1.5kW |

| IRK-03 | 15 | 350 | 4200 | 3700 | 2200 | 1500 | 2.2kW |

| IRK-04 | 30 | 450 | 4800 | 4200 | 2600 | 1700 | 2.2kW |

| IRK-05 | 60 | 550 | 5700 | 5000 | 3300 | 1900 | 3.7kW |

| IRK-06 | 100 | 650 | 6700 | 5900 | 4000 | 2100 | 3.7kW |

| IRK-07 | 150 | 750 | 7400 | 6500 | 4500 | 2300 | 5.5kW |

Typical Flow Sheet

Related Products

-

TSUBOSAN 12-PCS Length 170mm Die Sinker’s-Assorted Files

-

Fujii Denko SAF-NV93 (Noviron) Industrial Safety Belt

-

Kokosha BGLS211 Emergency Light Self Contained Battery Type

-

NAGANO KEIKI CB15 Pressure Switch For Direct Control

-

Gentos Explorer EX-300H LED Lantern

-

Watanabe WRBI-AO8 Analog Output Module – Remote I/O