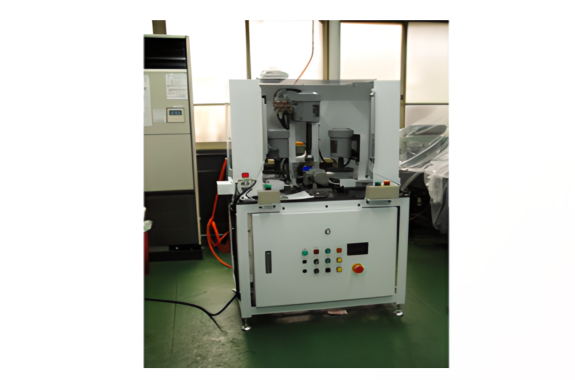

Japan, Matsuda Seiki

Matsuda Seiki Double Tooth Deburring Machine

Product: Made in Japan

Manufacturer: Matsuda Seiki

Model: Double Tooth Deburring

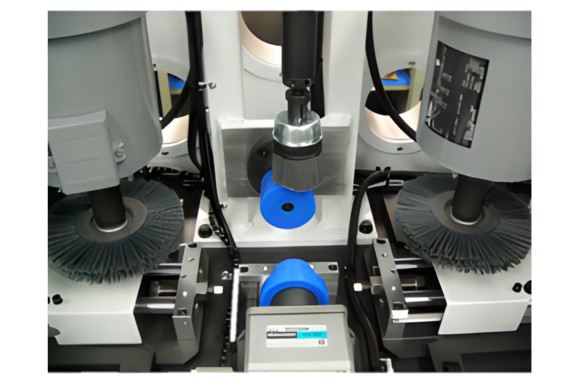

Removing gear burrs has become significantly easier! With our automatic deburring system, we directly address the outer diameter of gears using a brush, significantly streamlining the process. When we simultaneously apply multiple brushes. We drastically minimize the time and effort required for their attachment and detachment. Thereby enhancing efficiency.

Now, let’s take a closer look at our groundbreaking solution, the “Deburring Machine for Double Tooth Sprockets,” meticulously designed with your specific needs in mind:

– Machine Name: Deburring Machine for Two-Tooth Sprockets.

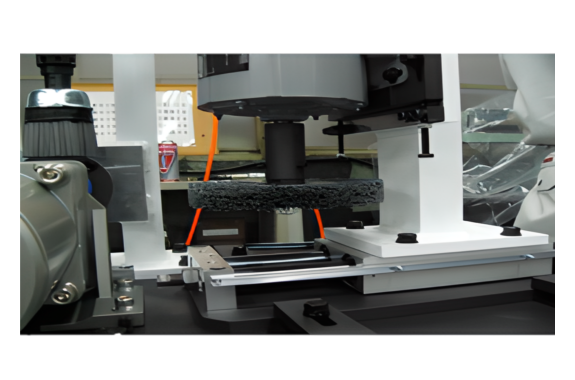

– Focusing on the Core of the Machine – The Work Head Part:

– We have optimized the work rotation speed to a maximum of 5 RPM (60Hz), guaranteeing a smooth and efficient deburring process.

– The slide’s movement capacity extends up to a maximum of 100mm, providing precise control during the deburring operation.

– Utilizing an air cylinder for the slide drive method, we ensure durability along with effortless operation.

– Impressively, our machine includes a detection function for both the forward and backward ends, automatically switching to maintain continuous, manual intervention-free operation.

Additionally, our expertise doesn’t just cover deburring machines. We proudly design and manufacture a wide range of measuring devices and specialized machinery. If you need equipment tailored to your unique specifications, rest assured that our team is ready to design and produce solutions that will not only meet but exceed your expectations.

In summary, our commitment transcends the provision of advanced equipment; we aim to deliver bespoke solutions that tackle the unique challenges faced by our clients, ensuring both their satisfaction and exceptional outcomes.