Drilling And Cutting, Japan, Miyakawa

Miyakawa B Type General Purpose Milling

Product Made in Japan

Manufacturer: Miyakawa

Model: B type

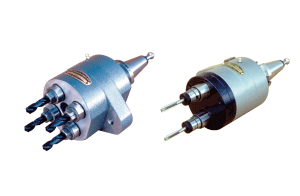

B type drill head for ATC

For ATC B type drill

|

Features

|

|

Attach the positioning block to the end face of the spindle of the machining center and use a multi-axis head. |

Mounting dimensions

|

Position & shape of positioning block | P | |

|

Q | ||

| W | |||

| S | |||

| θ | |||

| Machining center specification (Max) | D | ||

| L + length of cutting tool | |||

| weight |

Performance specification

| Model | Body outer diameter (mm) |

Types ofchucks | Scope of hole processing | Minimum pitch oftwo axes (mm) |

Length L (reference) (mm) |

Maximum speed (min – 1) |

Maximum machining drill diameter (S45C) (mm) |

Chuck grip diameter (mm) |

Weight (kg) (reference) |

|||

| Maximum diameter (mm) |

Minimum diameter (mm) |

2 axes | 4 axes | |||||||||

| BT 30 | 50D | 90 | C-6 | 55 | 40 | 24 | 162 | 4000 | 5 | 6 | 2.7 | 3.1 |

| BT 40 | 70D | 110 | C-6 | 70 | 55 | 24 | 177 | 4000 | 5 | 6 | 4.5 | 5 |

| C-10 | 60 | 29 | 8 | 10 | 5 | 5.7 | ||||||

| 80D | 120 | C-6 | 85 | 55 | 24 | 177 | 4000 | 5 | 6 | 5 | 5.5 | |

| C-10 | 80 | 60 | 29 | 8 | 10 | 5.5 | 6.2 | |||||

| 90D | 130 | C-6 | 95 | 55 | 24 | 171 | 4000 | 5 | 6 | 5.5 | 6 | |

| C-10 | 90 | 60 | 29 | 8 | 10 | 6 | 6.7 | |||||

| C-13 | 85 | 65 | 34 | 196 | 3000 | 10 | 13 | 7 | 8 | |||

| MT-1 | 80 | 70 | 48 | 205 | 12 | 14 | 8 | 9.5 | ||||

| 100D | 140 | C-6 | 105 | 55 | 24 | 177 | 3000 | 5 | 6 | 6 | 6.5 | |

| C-10 | 100 | 60 | 29 | 8 | 5 | 8.5 | 7.2 | |||||

| C-13 | 95 | 65 | 34 | 196 | 2000 | 10 | 13 | 8 | 9 | |||

| MT-1 | 90 | 70 | 48 | 205 | 12 | 14 | 9 | 10.5 | ||||

| 110D | 160 | C-6 | 125 | 55 | 24 | 177 | 2000 | 5 | 6 | 7 | 8 | |

| C-10 | 120 | 60 | 29 | 8 | 10 | 7.5 | 9 | |||||

| C-13 | 115 | 65 | 34 | 196 | 10 | 13 | 9.5 | 11 | ||||

| MT-1 | 110 | 70 | 40 | 205 | 12 | 14 | 10.5 | 12.5 | ||||

| BT 50 | 90D | 130 | C-6 | 105 | 70 | 24 | 209.5 | 3000 | 5 | 6 | 10.5 | 11 |

| C-10 | 100 | 70 | 29 | 8 | 10 | 11 | 11.7 | |||||

| C-13 | 95 | 80 | 34 | 229.5 | 2000 | 10 | 13 | 11 | 12 | |||

| MT-1 | 80 | 70 | 48 | 237.5 | 12 | 14 | 12 | 13.5 | ||||

| 100D | 140 | C-6 | 105 | 70 | 24 | 209.5 | 2000 | 5 | 6 | 10.5 | 11 | |

| C-10 | 100 | 70 | 29 | 8 | 10 | 11 | 11.7 | |||||

| C-13 | 95 | 80 | 34 | 229.5 | 10 | 13 | 12 | 13 | ||||

| MT-1 | 90 | 80 | 48 | 237.5 | 12 | 14 | 13 | 14.5 | ||||

| 110D | 160 | C-10 | 120 | 75 | 29 | 209.5 | 2000 | 8 | 10 | 12 | 13.5 | |

| C-13 | 115 | 80 | 34 | 229.5 | 10 | 13 | 13 | 14.5 | ||||

| MT-1 | 110 | 85 | 48 | 237.5 | 12 | 14 | 14 | 18 | ||||

| MT-2 | 100 | 90 | 52 | 278.5 | 19 | 23 | 15 | 17.5 | ||||

| 120D | 180 | C-10 | 140 | 75 | 29 | 209.5 | 1500 | 8 | 10 | 13 | 14 | |

| C-13 | 135 | 80 | 34 | 229.5 | 10 | 13 | 14 | 15.5 | ||||

| MT-1 | 130 | 85 | 48 | 237.5 | 12 | 14 | 15 | 17 | ||||

| MT-2 | 120 | 90 | 52 | 278.5 | 19 | 23 | 16 | 18.5 | ||||

For ATC B type tap

|

Features

|

|

Attach the positioning block to the end face of the spindle of the machining center and use a multi-axis head. |

Mounting dimensions

|

Position & shape of positioning block | P | |

|

Q | ||

| W | |||

| S | |||

| θ | |||

| Machining center specification (Max) | D | ||

| L + length of cutting tool | |||

| weight |

Performance specification

| Model | Body outer diameter (mm) |

Types ofchucks | Scope of hole processing | Minimum pitch oftwo axes (mm) |

Length L (reference) (mm) |

Maximum speed (min – 1) |

Maximum machining drill diameter (S45C) (M) |

Chuck grip diameter (M) |

Weight (kg) (reference) |

|||

| Maximum diameter (mm) |

Minimum diameter (mm) |

2 axes | 4 axes | |||||||||

| BT 40 | 70T | 110 | C-6 | 70 | 55 | 23 | 216.5 | 1200 | M5 | M6 | 4.5 | 5.3 |

| C-10 | 60 | 30 | 222.5 | M8 | M12 | 5 | 6 | |||||

| 80T | 120 | C-6 | 85 | 55 | 23 | 216.5 | 1200 | M5 | M6 | 5 | 5.8 | |

| C-10 | 80 | 60 | 30 | 222.5 | M8 | M12 | 5.5 | 6.5 | ||||

| 90T | 130 | C-6 | 95 | 55 | 23 | 216.5 | 1200 | M5 | M6 | 5.5 | 6.3 | |

| C-10 | 90 | 60 | 30 | 222.5 | M8 | M12 | 6 | 7 | ||||

| C-13 | 85 | 65 | 34 | 254 | 800 | M12 | M16 | 7.5 | 9 | |||

| 100T | 140 | C-6 | 105 | 55 | 23 | 216.5 | 1200 | M5 | M6 | 6 | 6.8 | |

| C-10 | 100 | 60 | 30 | 222.5 | M8 | M12 | 7 | 8 | ||||

| C-13 | 95 | 65 | 34 | 254 | 800 | M12 | M16 | 10 | 12 | |||

| 110T | 160 | C-6 | 125 | 55 | 23 | 216.5 | 1200 | M5 | M6 | 7 | 8 | |

| C-10 | 120 | 60 | 30 | 222.5 | M8 | M12 | 7.5 | 9 | ||||

| C-13 | 115 | 65 | 34 | 254 | 800 | M12 | M16 | 10 | 12 | |||

| BT 50 | 90T | 130 | C-6 | 95 | 65 | 23 | 249 | 1200 | M5 | M6 | 9.5 | 10.3 |

| C-10 | 90 | 65 | 30 | 255 | M8 | M12 | 10 | 11 | ||||

| C-13 | 85 | 70 | 34 | 286.5 | 800 | M12 | M16 | 11.5 | 13 | |||

| 100T | 140 | C-6 | 105 | 70 | 23 | 249 | 1200 | M5 | M6 | 10.5 | 11.3 | |

| C-10 | 100 | 70 | 30 | 255 | M8 | M12 | 11 | 12 | ||||

| C-13 | 95 | 80 | 34 | 286.5 | 800 | M12 | M16 | 12.5 | 14 | |||

| 110T | 160 | C-6 | 115 | 75 | 23 | 249 | 1200 | M5 | M6 | 11.5 | 12.5 | |

| C-10 | 110 | 75 | 30 | 255 | M8 | M12 | 12 | 13.5 | ||||

| C-13 | 105 | 85 | 34 | 286.5 | 800 | M12 | M16 | 13.5 | 15.5 | |||

| 120T | 180 | C-6 | 125 | 75 | 23 | 249 | 1200 | M5 | M6 | 12.5 | 13.5 | |

| C-10 | 120 | 75 | 30 | 255 | M8 | M12 | 13 | 14.5 | ||||

| C-13 | 115 | 85 | 34 | 286.5 | 800 | M12 | M16 | 14.5 | 16.5 | |||