Japan, Nippon Seimitsu

Nippon Seimutsu ACV-MP2 Central Cleaner

Product Made in Japan

Manufacturer: Nippon Seimitsu Co., Ltd.

Model: ACV-MP2

What is a Central Cleaning System?

This system allows you to easily clean wide-area cleaning areas and dust collection points, even across multiple floors. You can perform cleaning by inserting a dedicated hose (attachment) into the installed inlet valve, significantly reducing the amount of work. The greatest feature of this system is its ability to collect sucked-in dust and air in one place without returning them to the work area, thus increasing the cleanliness of the work area. This system is ideal for food factories, pharmaceutical factories, semiconductor factories, and other facilities with clean rooms.

Equipment for central cleaning systems

- This system easily collects dust even when the cleaning area and dust collection points are wide.

- We isolate the equipment storage area, preventing the scattering of exhaust and collected dust, making it extremely clean.

- As a pioneering manufacturer, we offer a unique model lineup and options.

- You can freely combine operation methods, separators, inlet valves, and other systems.

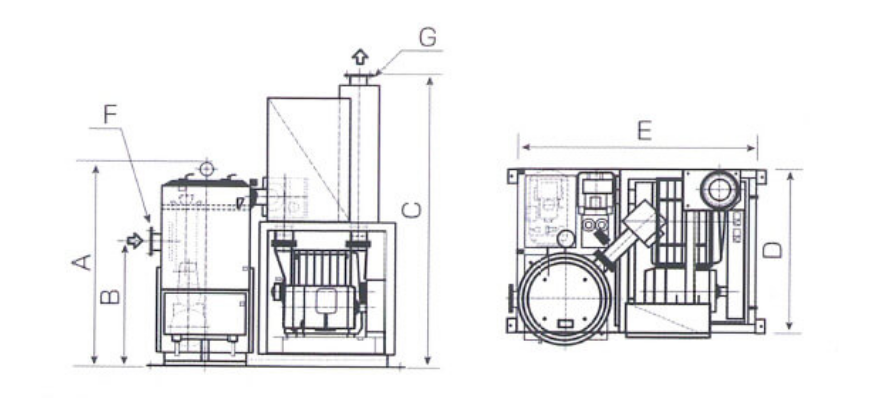

Piped cleaning device: Central cleaner [Compact design]

This compact and revolutionary unit can be used in small to large spaces. It uses a pulse jet system for filter removal, allowing for continuous operation, and you can use plastic bags to remove dust. Additionally, you can easily replace the molded filter.

It is also possible to accommodate the ACV-MP2 automatic driving device.

Specifications

| MP2-55 | MP2-75 | MP2-110 | MP2-150 | ||

|---|---|---|---|---|---|

| Power supply (phase/V) | 3⌀ 200 | 3⌀ 200 | 3⌀ 200 | 3⌀ 200 | |

| Power output (kW) | 5.5 | 7.5 | 11 | 15 | |

| Air volume (m3/min) | 6 | 6 | 10 | 12 | |

| Static Pressure (kPa) | 20.6 | 22.5 | 23.5 | 27.4 | |

| Separation Method | Bag filter separation method | Bag filter separation method | Bag filter separation method | Bag filter separation method | |

| Filter area (m²) | 3.4 | 3.4 | 3.4 | 3.4 | |

| Dust-off method | Pulse jet method | Pulse jet method | Pulse jet method | Pulse jet method | |

| Dust collection capacity (ℓ) | 65 | 65 | 65 | 65 | |

| Weight (kg) | 480 | 520 | 700 | 770 | |

| Dimensions (mm) | A | 1490 | 1490 | 1490 | 1490 |

| B | 900 | 900 | 900 | 900 | |

| C | 1850 | 1850 | 2130 | 2130 | |

| D | 1187 | 1187 | 1187 | 1187 | |

| E | 1600 | 1700 | 1700 | 1700 | |

| F | 65A | 65A | 100A | 100A | |

| G | 100A | 100A | 150A | 150A | |

Dimensions