Hole Puncher, Japan, Ogura, Other Tools

Ogura HPC-NF188W Electro-Hydraulic Hole Punchers

Product Made in Japan

Manufacturer: Ogura

Model: HPC-NF188W

Features of HPC-NF188W

The new “N” series punchers are double-acting and have a newly designed punch holder for longer life. The punch is also redesigned so that only one “N” series punch is required to punch the range of materials: mild steel, stainless steel, angle iron, and channel steel. The center of the punch has been made wider for easier positioning.

- Both punching and retracting are completed by hydraulic power. This solves the “punch jammed” problem and allows faster work at the site.

- As a result of reviewing the basic structure of the tool from the user’s point of view, we changed the design of the die, punch & punch holder to make them more durable and to make the setting of the punch & die easier.

- Only one die for flat bar, angle steel and channel flange. It is not necessary to change the die when punching different materials or thicknesses.

∗Thinner material (t2-3.2mm) may have some burrs or deformation.

“N” series puncher for C-shaped steel (Lip Channel)

- “Double acting” hydraulic return for jam free operation.

- New punch design makes it easier to confirm the hole position.

- Hole puncher is specifically designed to provide high quality holes quickly and efficiently.

- MAX. HOLE SIZE: φ18 ⁄ t8mm(MILD STEEL)

Specification of HPC-NF188W

| Motor | Single phase 100V 710W 50 / 60Hz times Double insulation |

| Mass | 10.7kg |

| Body dimensions | 522 (L) x 149 (W) x 180 (H) mm |

| Depth | 38mm |

| Hole shape | Round / long hole |

| Maximum drilling capacity | General steel (SS400 equivalent): Φ18 / t8 |

| Stainless steel (SUS304): Φ18 / t6 | |

| Standard accessories | Punch Φ12mm Die SB12 Nut tightening bar Hexagon wrench (3, 4, 5, 6) Spanner (8 × 10) Strap Hydraulic oil Product case Work stand |

| Option | Foot switch |

Materials Dimensions of HPC-NF188W [Unit: mm]

Flat bar

Max: 75xt8 (Center Punching)

Angle Steel

Minimum 40 x 40 x t3

Maximum 75 x 75 x t6

Channel Flange

Minimum 75 × 40

Maximum 100 × 50

Round Punch & Die [Unit: mm]

| Round punch | Round die | Mild steel | Channel flange | Stainless steel |

|---|---|---|---|---|

| 6 | SB6 | t2 ~ t4 | – | t3 ~ t4 |

| 6.5 | SB6.5 | t2 ~ t6 | – | t3 ~ t4 |

| 8 | SB8 | t2 ~ t6 | – | t3 ~ t4 |

| 8.5 | SB8.5 | t2 ~ t6 | – | t3 ~ t4 |

| Ten | SB10 | t2 ~ t6 | t7.5 | t3 ~ t4 |

| 11 | SB11 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 12 | SB12 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 13 | SB13 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 14 | SB14 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 15 | SB15 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 16 | SB16 | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 18 | SB18 | t2 ~ t8 | t7.5 | t3 ~ t6 |

Oblong Punch & Die [Unit: mm]

| Oblong punch | Long die | Mild steel | Channel Flange | Stainless steel |

|---|---|---|---|---|

| 6.5 × 10 | 6.5 × 10B | t2 ~ t6 | – | t3 ~ t4 |

| 6.5 × 13 | 6.5 × 13B | t2 ~ t6 | – | t3 ~ t4 |

| 8.5 × 13 | 8.5 × 13B | t2 ~ t6 | – | t3 ~ t4 |

| 8.5 × 17 | 8.5 × 17B | t2 ~ t6 | – | t3 ~ t4 |

| 9 x 13.5 | 9 × 13.5B | t2 ~ t6 | – | t3 ~ t4 |

| 9 x 18 | 9 × 18B | t2 ~ t6 | – | t3 ~ t4 |

| 10×15 | 10 × 15B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 10×20 | 10 × 20B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 11 x 16.5 | 11 x 16.5B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 12×18 | 12 × 18B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 13 x 19.5 | 13 × 19.5B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 14 × 21 | 14 × 21B | t2 ~ t8 | t7.5 | t3 ~ t6 |

| 15 × 21 | 15 × 21B | t2 ~ t8 | t7.5 | t3 ~ t6 |

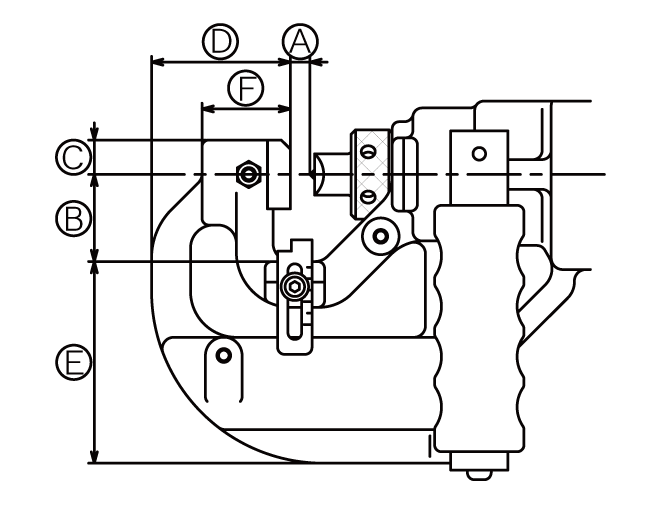

Punching Throat [Unit: mm]

A: 8.5 mm B: 38 mm C: 15 mm D: 61 mm E: 88 mm F: 39 mm

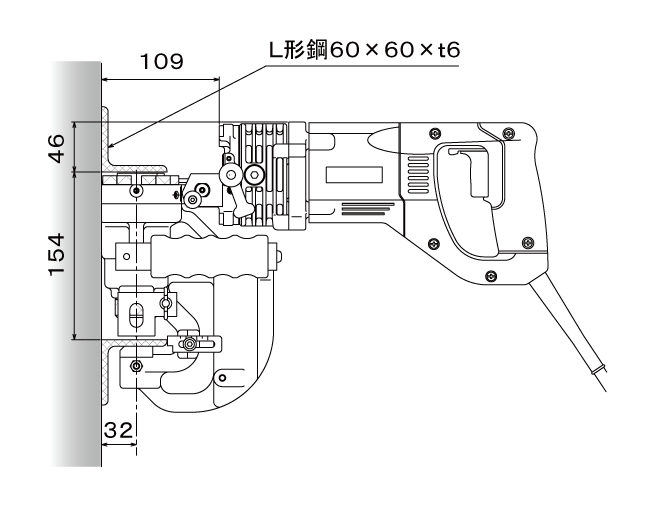

Dimensions for drilling holes from the wall [Unit: mm]

Related Products

-

Yamamoto Keiki Sealing Case Bimetal Thermometer

-

KETT ELECTRIC LABORATORY MT-200 Wood Chip Moisture Tester

-

Hammer Caster 505SA-UB Urethane Thermoplastic Wheel Scaffold Caster

-

Eagle Jack (Konno Corporation) HBS-41 Hydraulic Rebar Bender

-

MIKI NETSUREN CH-NF Hook With Intact Cam

-

Tosoku RE46 Series Manual Pulse Generator