Japan, Orientalmotor

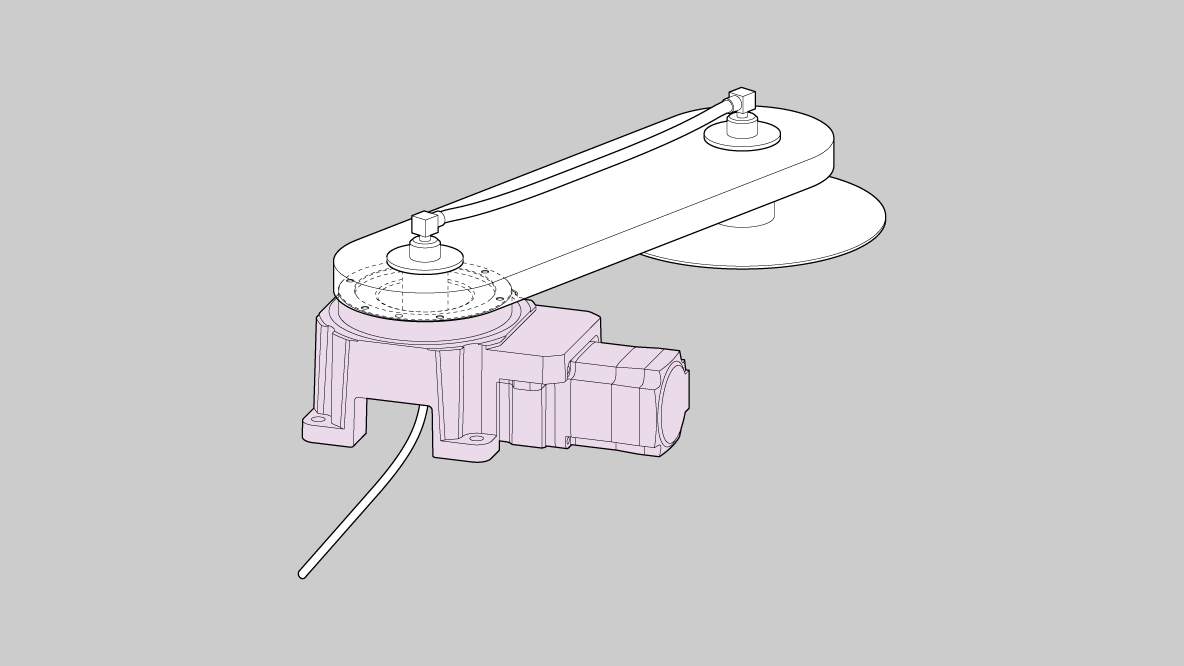

Orientalmotor DGII Series Hollow Rotary Actuator

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: DGII Series

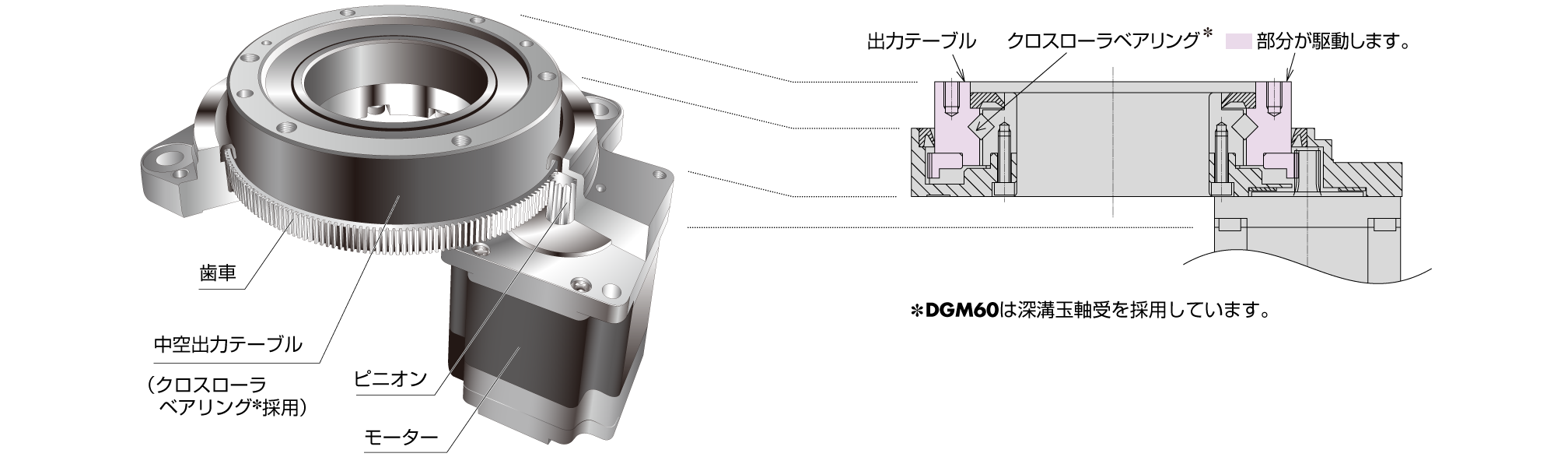

Actuator section features

We will introduce the features of the DGⅡ series using the AZ series as an example.

Direct connection of load is possible

By directly attaching tables, arms, and other components with a large moment of inertia, you eliminate the need for connecting parts such as collars. Consequently, this approach streamlines the design and assembly process while also reducing parts costs, ultimately resulting in a more efficient and cost-effective overall process.

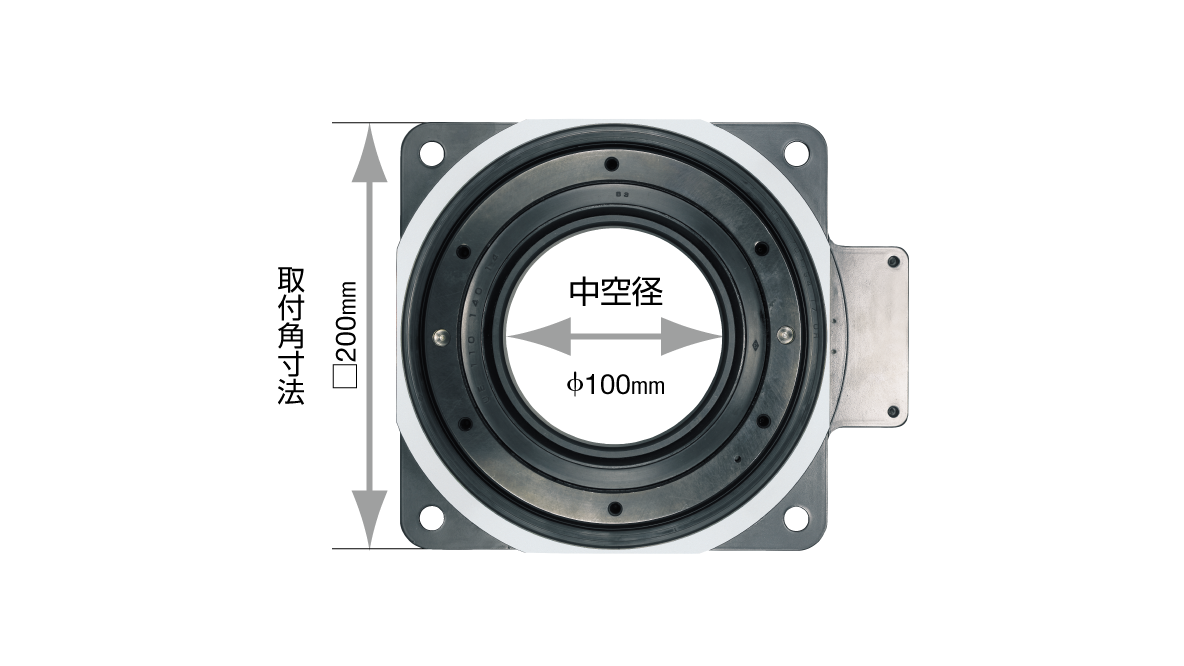

Large diameter hollow output table

You can use the hollow hole for cable wiring, air piping, or liquid piping, thus allowing for streamlined and organized installations that efficiently meet various needs. Moreover, utilizing the hollow hole in this manner not only further enhances the system’s overall functionality and flexibility but also allows for more versatile applications, thereby improving the efficiency of the entire setup. Furthermore, this approach adapts more readily to diverse operational needs, consequently ensuring optimal performance and reliability.

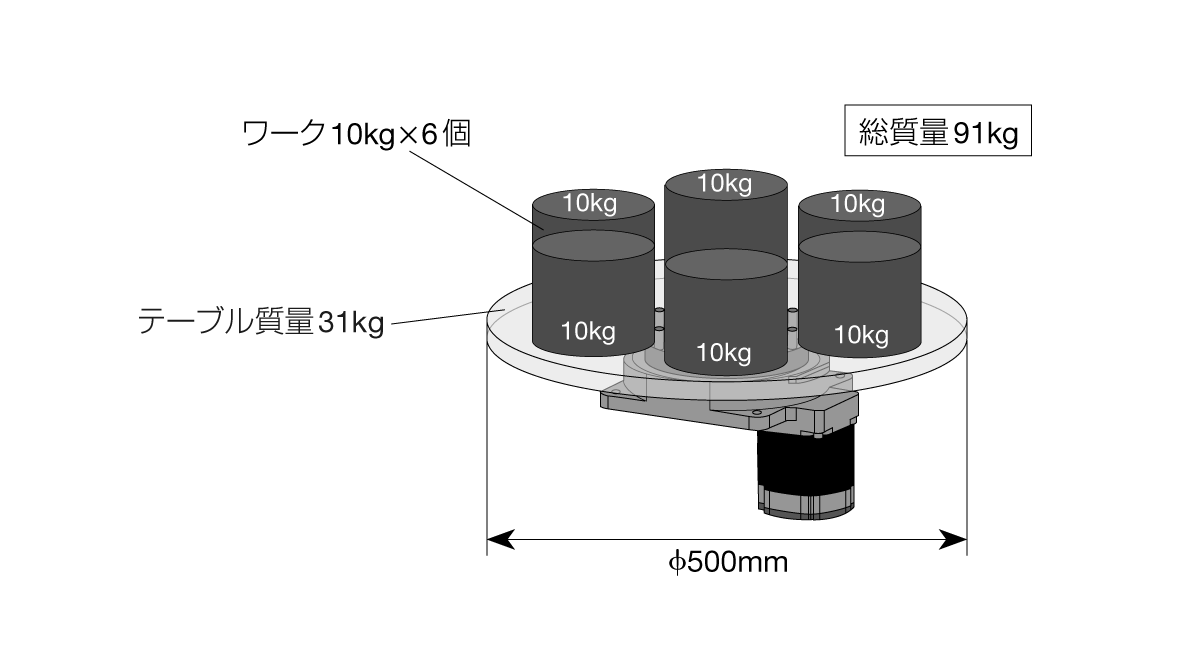

High strength

Capable of driving heavy and large workpieces

The maximum allowable axial load is 4000N. The maximum allowable moment is 100N・m. It can drive workpieces with large mass and moment of inertia.

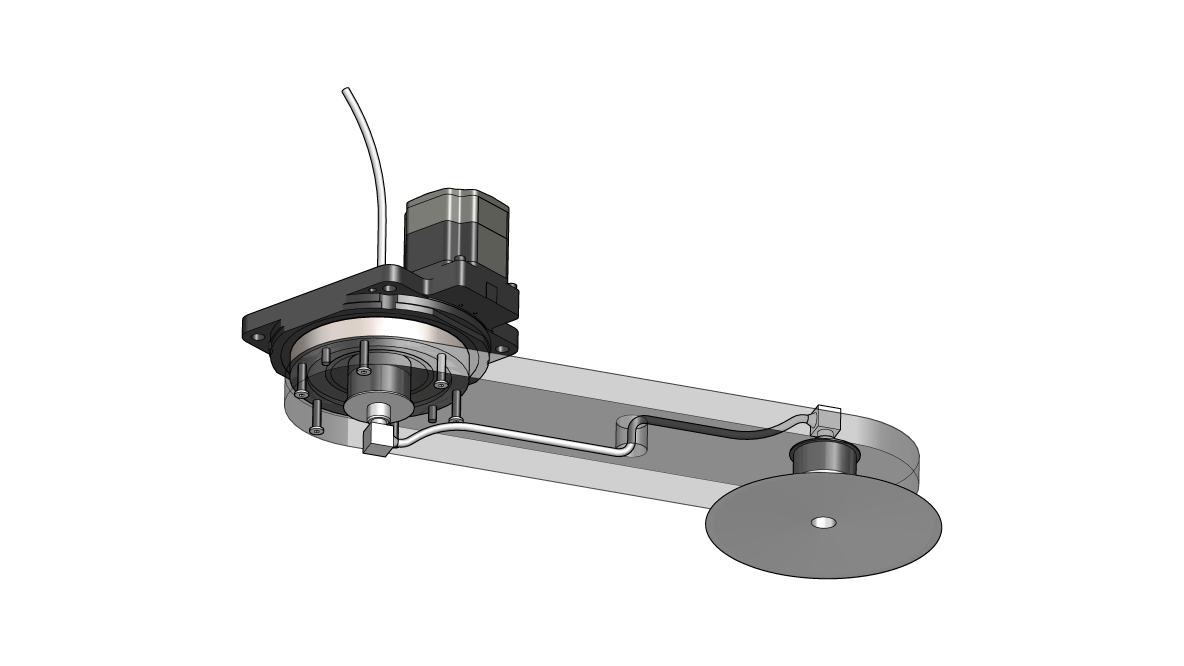

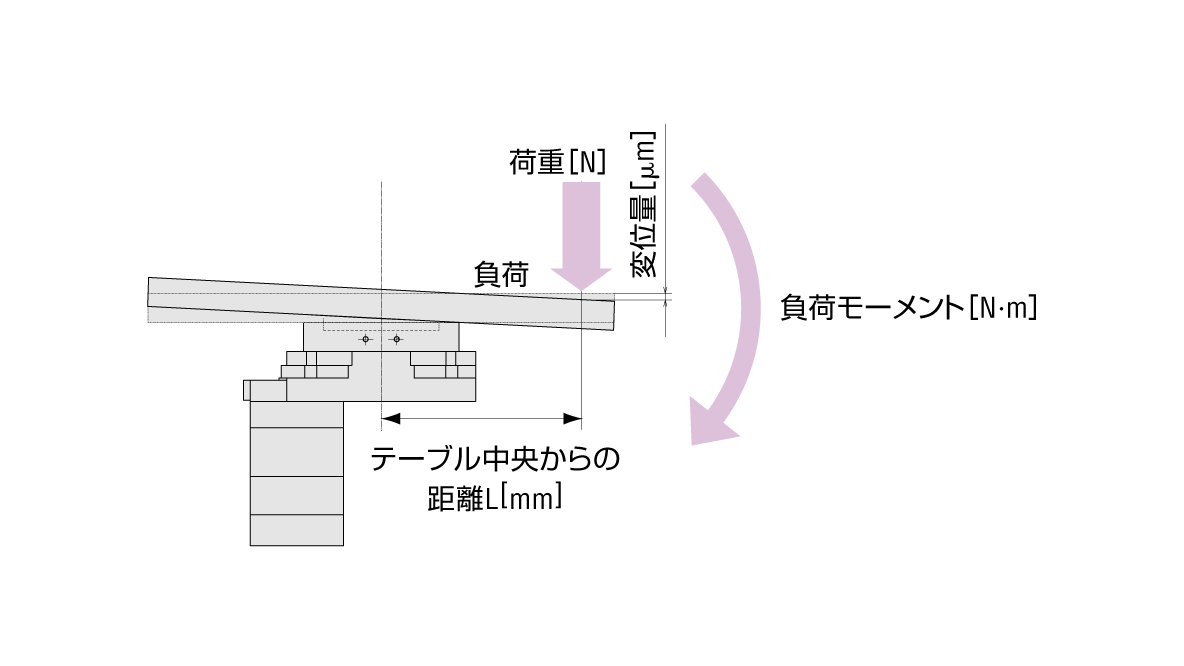

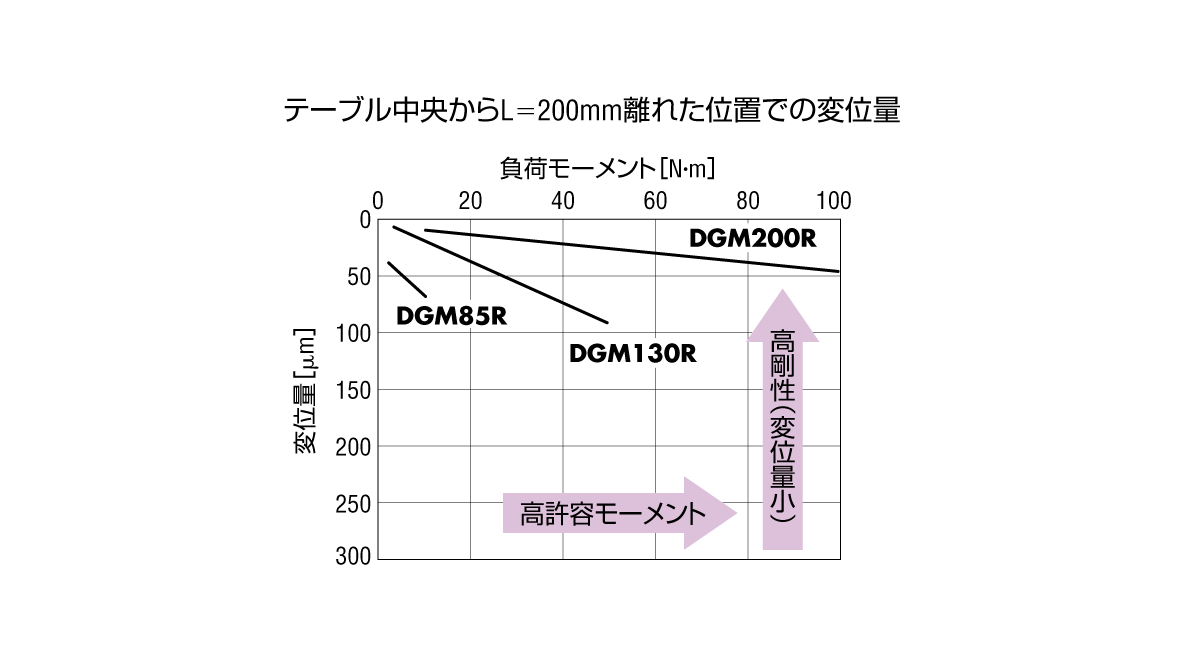

Small surface vibration

You can place the workpiece away from the center of the output table, thereby allowing for more efficient use of the workspace and better accommodating various sizes and shapes of workpieces. Furthermore, by positioning the workpiece off-center, you not only optimize the workflow but also improve overall productivity. Consequently, this method leads to better space utilization and enhances the efficiency of the working process, ultimately resulting in increased output and streamlined operations.

High positioning accuracy

| Motor lengthwise | Motor lateral direction | |

|---|---|---|

| Backlash | No backlash | 6 arcmin(0.1°) |

| Repeated positioning accuracy | ±15 arcsec (±0.004°) | ±30 arcsec (±0.008°) |

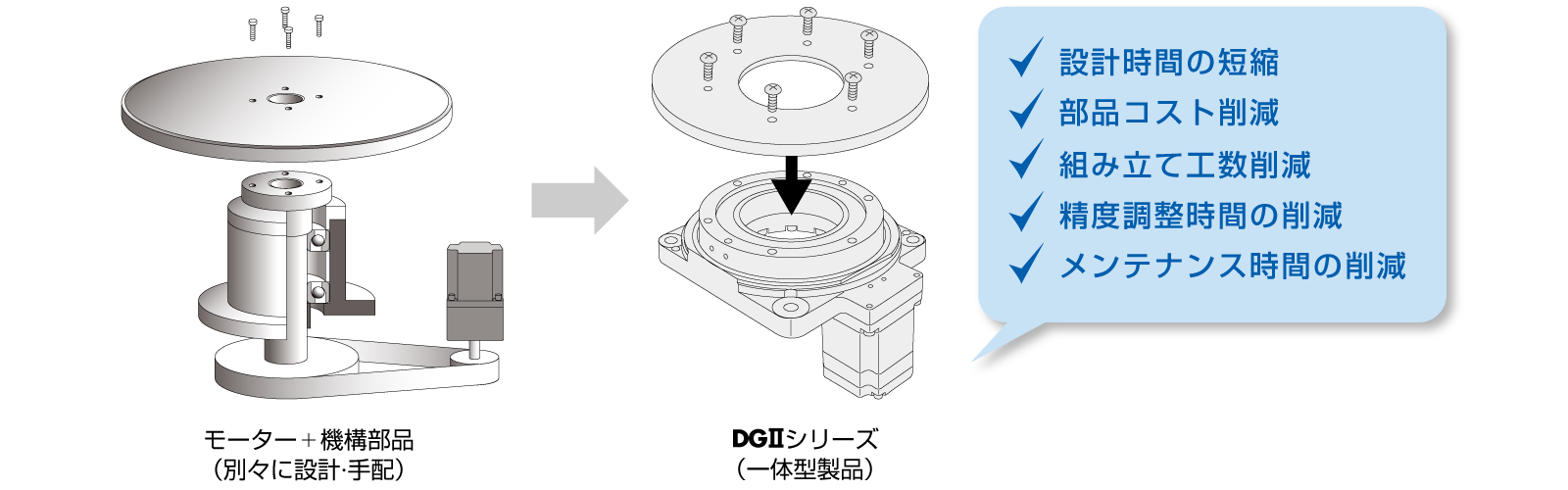

Integrated structure reduces equipment start-up time

Reduce the time required for “design,” “assembly,” and “adjustment”

By directly attaching the output table to the equipment table or arm, you not only simplify the setup process and reduce the need for additional connecting parts but also enhance stability. Furthermore, this direct attachment streamlines the overall assembly, thereby making the equipment more efficient and user-friendly.

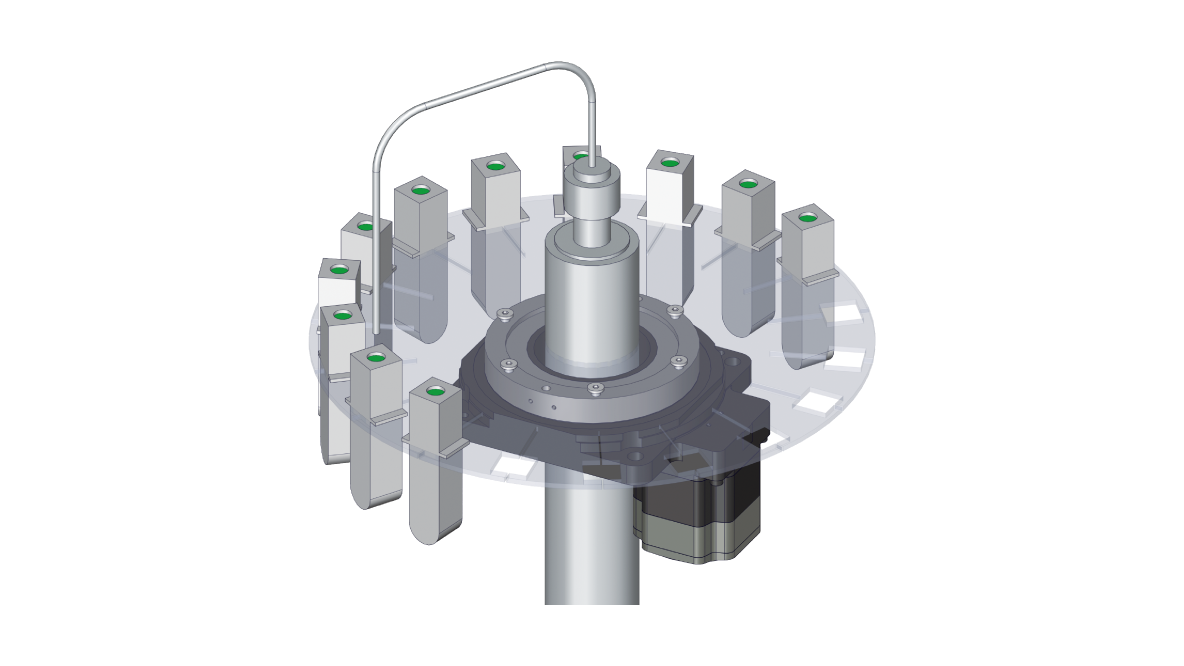

Cross roller bearings provide high output drive

The diagram above shows the motor’s vertical structure. The structure of the hollow output table is the same for the motor’s horizontal structure.

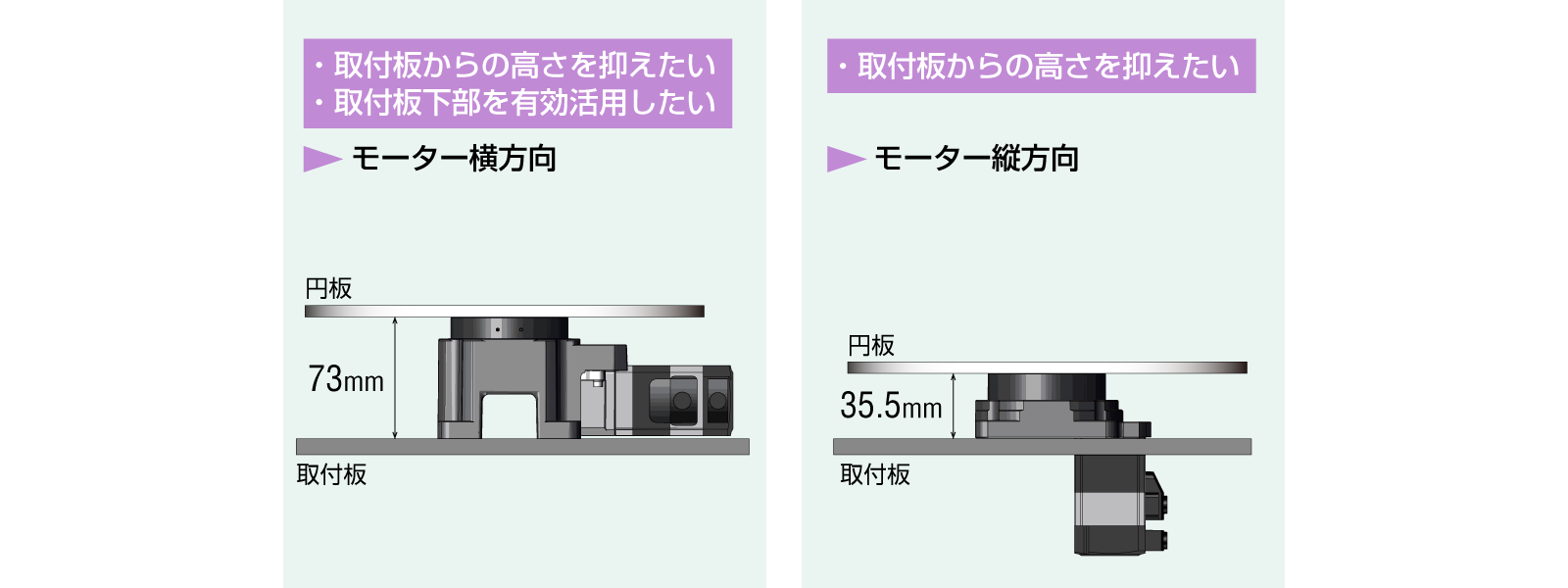

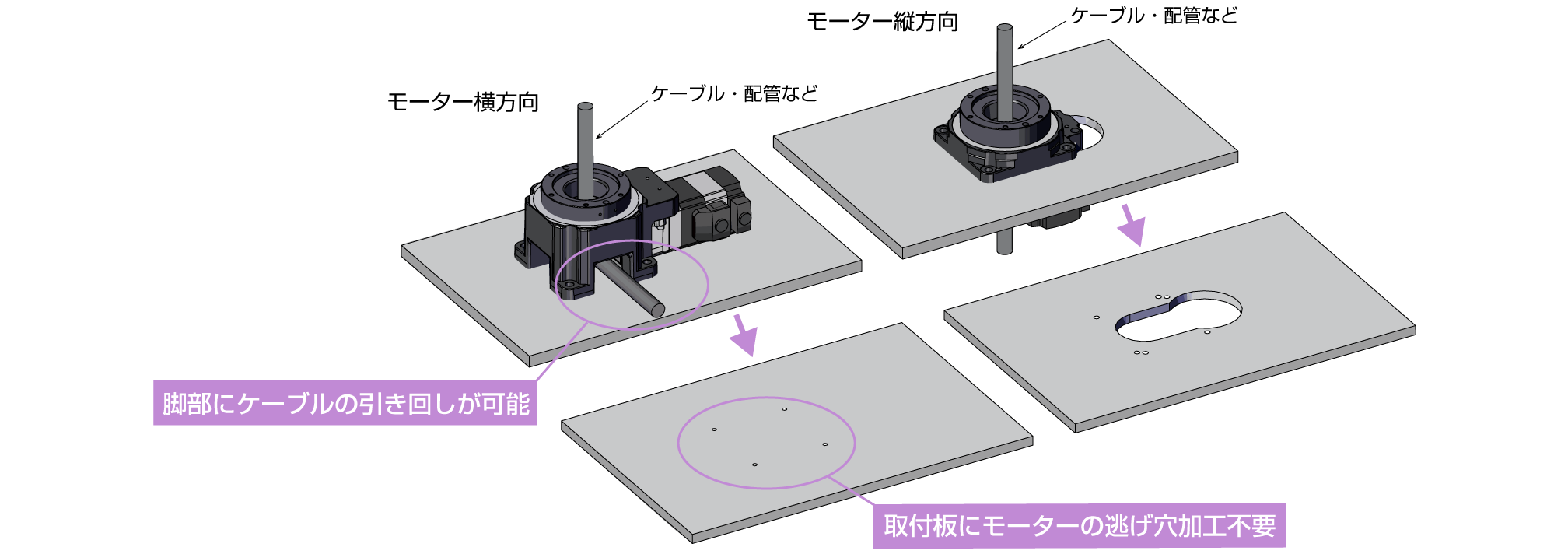

Use according to the space

Motors are available in vertical and horizontal orientations, allowing you to choose the orientation that best suits the installation space within your equipment.

Advantages of lateral motor orientation

Additionally, the mounting plate can be simplified due to the elimination of the need for drilling a relief hole for the motor. Moreover, cables, piping, and other components can be conveniently routed between the legs under the table.

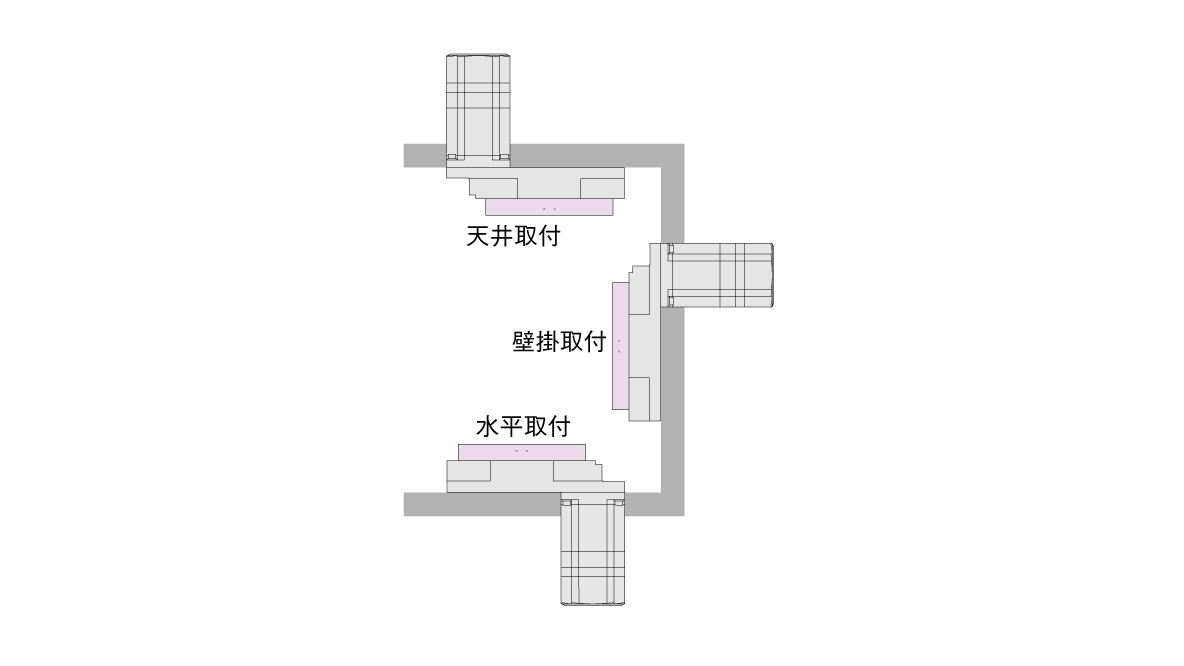

Selectable installation direction

You can install the DGⅡ series not only horizontally but also on the ceiling or a wall, thereby significantly expanding the scope of equipment design and allowing for more versatile and innovative configurations. Moreover, this adaptability further enhances the overall functionality and efficiency of the equipment in various environments.

Motor lengthwise

Motor lateral direction

Examples of use and applications

Applications where load moment is applied

Low Speed and Low Vibration Applications:

The micro-step drive method and smooth drive function enable low-vibration rotation, even at low speeds. This makes the DGII series ideal for applications such as liquid application devices, where stable coating is essential, even at low speeds.

High-Precision Positioning:

The DGII series eliminates hunting, the phenomenon of slight shaft movement when stopped. This makes it perfect for applications like image inspection equipment, where capturing accurate images is critical.

Applications with Variable Load Inertia:

With no need for gain adjustment, the DGII series consistently performs as intended, even in equipment with load fluctuations. This feature proves invaluable in applications such as disc manufacturing equipment, where the number of discs being transported may vary.

Drivers can be selected according to the host system

We offer a lineup that can support a variety of controls, systems, and interfaces.

| Driver Type | Supported Interfaces | Single Axis Driver | |||

|---|---|---|---|---|---|

| AC power in | DC power in | ||||

Equipped AZ series Equipped AZ series |  Equipped AZX series Equipped AZX series |  Equipped AZ series Equipped AZ series | |||

| Network compatibility | Direct control of the driver from a higher-level control device | EtherCAT | ○ | ○ | ○ |

| EtherNet/IP™ | ○ | ○ | ○ | ||

| PROFINET | ○ | ○ | ○ | ||

| MECHATROLINK-Ⅲ | ○ | – | – | ||

| SSCNETⅢ/H | ○ | – | – | ||

| Built-in positioning function | Operation data is stored in the driver. Control is possible with Modbus (RTU) and I/O . CC-Link control is possible by using a network converter. | Modbus(RTU) I/O CC-Link * | ○ | – | ○ |

| Pulse train input with RS-485 communication | Controlled by pulse signals. Motor status information can be monitored via Modbus (RTU). | Pulse train Modbus (RTU) | ○ | – | ○ |

| Pulse train input | Pulse signal control | Pulse train | ○ | – | ○ |

Additionally, EtherCAT® is a patented technology licensed from Beckhoff Automation GmbH (Germany) and is a registered trademark, while EtherNet/IP™ is a trademark of ODVA, and PROFINET is a trademark or registered trademark of PROFIBUS Nutzerorganisation eV (PNO).

Moreover, MECHATROLINK is a registered trademark of the MECHATROLINK Association, and SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation. Finally, CC-Link is a registered trademark of the CC-Link Partner Association.

Lineup featuring the AZ series

Because we use the same motor, the operation and maintenance methods remain consistent.Electric actuator (AZ series installed)

| Motorized Slider | Electric Cylinder | Compact Electric Cylinder | Rack and pinion system | Electric Gripper | Hollow Rotary Actuator |

|---|---|---|---|---|---|

| EAS serie EZS series EZSH series | EAC Series | DR series DRS2 series | L-Series | EH Series | DGⅡ series |

The power input of the installed motor differs depending on the series. Please check the page for each series for detailed lineup.