Japan, Orientalmotor

Orientalmotor LJ Linear Heads

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: LJ

Features of the Linear Head

Compact Size and Maximum Transportable Mass of 200 kg

Maximum Transportable Mass 200 kg

Larger-diameter pinion with increased gear strength realizes a maximum transportable mass of 200 kg*

*The maximum transportable mass varies depending on the gearhead’s gear ratio and the motor to be combined.

Maximum Stroke 700 mm

Product line with strokes of 100~700 mm

Fix the Rack to Make the Best Use of Space

The motor can run by itself by fixing both ends of the rack.

Effective for installation where motor space is difficult to secure.

Contributes to Improved Design Efficiency

Reduces Startup Time From Design

Compared to building the rack-and-pinion mechanism on your own, the number of parts used and the labor required for design and assembly can be reduced.

Reduced Labor for Assembly and Maintenance

Can be Easily Combined With a Parallel Shaft Gearhead

Installation and maintenance of the motor can be easily performed.

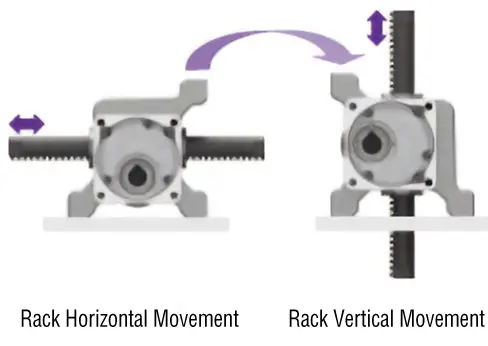

The Rack Can be Mounted Both Horizontally and Vertically

The ability to freely choose the mounting direction adds to improved ease of design and cost reductions through the sharing of parts.

Comparison of LJ Linear Head and LH Linear Head

Here is a comparison of the specifications of the 2 linear heads. Select the linear head that best suits your application and operating conditions.

| LJ Linear Head | LH Linear Head | |

|---|---|---|

| Maximum Transportable Mass | 200 kg*1 | ~70 kg |

| Stroke | 100~700 mm | 100~700 mm |

| Operating Speed | ~452 mm/s*1 |

|

| Combination Motor |

|

|

| Linear Head Shape (Rack moving direction) | The rack can be mounted both horizontally and vertically | 2 types available  |

| Motor Assembly Method | Parallel shaft gearhead + Motor assembled | Motor assembled  |

*1 Varies depending on the gearhead’s gear ratio and the motor to be combined.

*2 Click here for information about the combination with the αSTEP AZ Series

Applications

The rack-and-pinion mechanism, which can be applied to a variety of applications, is a user-friendly product that can be selected as if it were a component.

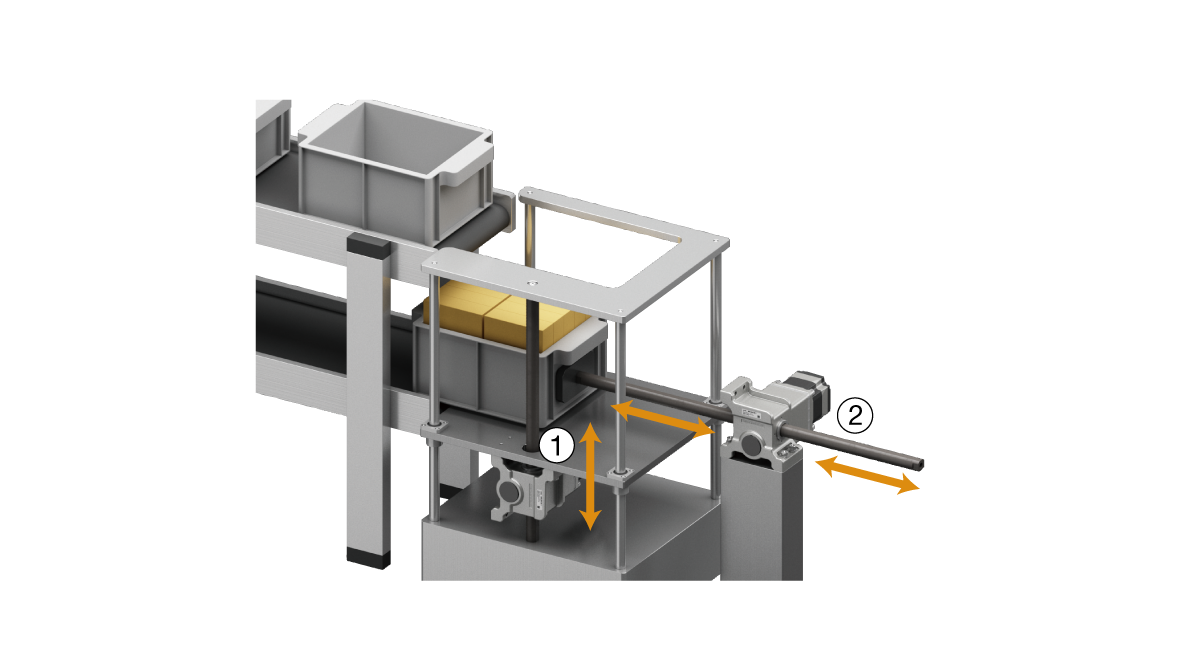

Bucket Transfer Belt Conveyor

① Fix the rack and drive the motor vertically

② Fix the motor and drive the rack horizontally

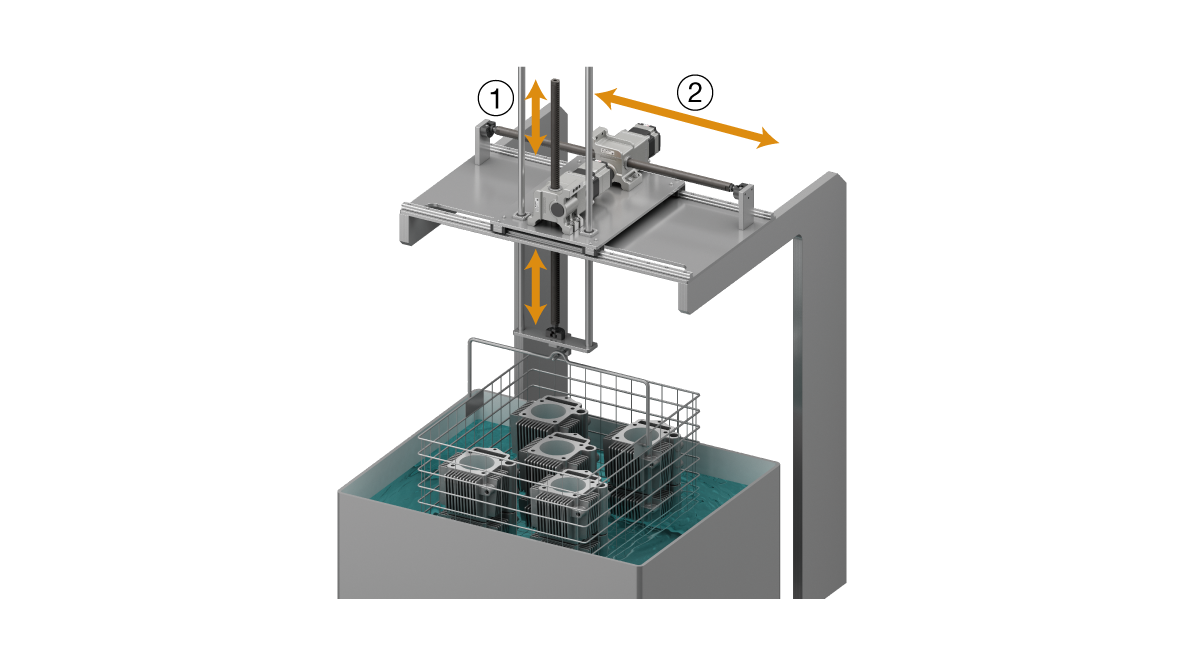

Machine Parts Cleaning Equipment

① Fix the motor and drive the rack vertically

② Fix the rack and drive the motor horizontally

Product Line

Please purchase “linear head,” “gearhead,” and “motor” separately.

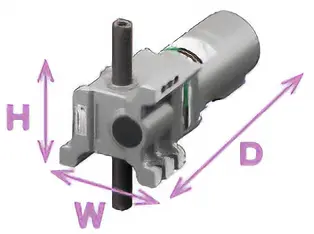

| Linear Head Product Line (Combined motors output power W) | W × H × D*1 [mm] | Maximum Transportable Mass kg*2 (Operating speed mm/s*2) | Stroke [mm] | |||

|---|---|---|---|---|---|---|

| LJ Linear Head | 60 | 140 × 140 × 293 | 14 (376) | ~ | 152 (9.4) | 100, 200, 300, 400, 500, 600, 700 |

| Maximum transportable mass and operating speed vary depending on the gearhead’s gear ratio. | ||||||

| 100 | 140 × 140 × 314 | 23 (376) | ~ | 200 (15) | 100, 200, 300, 400, 500, 600, 700 | |

| Maximum transportable mass and operating speed vary depending on the gearhead’s gear ratio. | ||||||

*1 When the gear ratio of the parallel shaft gearhead is 180

*2 Calculated from permissible torque and rotation speed of parallel shaft gearhead at power supply frequency of 50 Hz

Related Products

-

Gentos GF-104RG Flashlight

-

Nakatani Kikai CB10 Concrete Breaker (Clutch Type)

-

Kitz CS-TNE, FBS-TNE Type CS/FBS Pneumatic Actuators/Class 10K Horizontal 3-way Bronze Ball Valves

-

NAGANO KEIKI PC20 Programmable Pressure Controller

-

Kikusui Tape No.169G Spat Cloth Curing Green Tape

-

NAGANO KEIKI GF3 Pressure Measurement Instruments