Japan, Tanitec

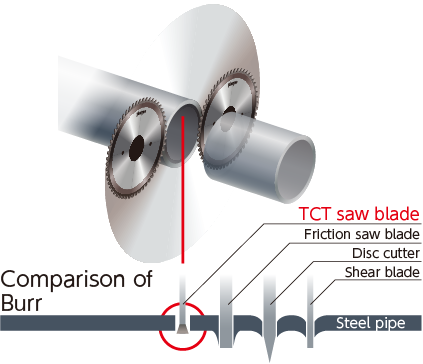

Tanitec TCT Saw Blade for Milling Cutter

Product Made in Japan

Manufacturer: Tanitec

TCT Saw Blade for Milling Cutter

It is TCT saw blade that is especially designed for cutting of the welded tube, structural column with flying cut-off machine in the mill factory. The cutting cycle time for flying cut-off machine is limited because the flying machine and mill conveyor speed is required to be synchronized. This is why TCT Saw Blade is designed for great performance with high circumference and feed speed. Our cutting technologies respond to those requirements and realize the stable blade life. Not only for new blade also for scrap blade, we deal with resharpening services and keep on proposing better cutting performance. This blade is used with NAKATA(SHINKO), KUSAKABE, MITSUBISHI, SUMITOMO, and THERMATOOL machine.

| Customer Information of Milling Cut Off | ||||||

|---|---|---|---|---|---|---|

| Material to be cut. | Circumferential Speed V (m/min) | Engaging Feed SZ1(mm) Orbital Feed SZ2 (mm) | Saw Blade Kerf (mm) | Method | ||

| Range | Thickness Quality Tensile Strength (MPa) | |||||

| CustomerA | ⟩300~ ⟩450 | 9~19mm SS400 SM500A | 280(t9) 260(t12) 250(t16) | 0.10(t9) 0.10(t12) 0.08(t16) 0.18(t9) 0.18(t12) 0.16(t16) | 350×48Z 360×40Z 4.1(48Z) 5.4(40Z) | Four Blades |

| CustomerB | ⟩200~ ⟩450 φ12”~ φ24” | 6.4~19mm ≦500 | 300(t6.9) 280(t10.3) 260(t16) 240(t19) | 0.1 0.18 | 350×48Z 350×64Z 4.3 | Four Blades |

| CustomerC | ⟩100~ ⟩200 φ114.3~ φ267.4 | 2~12mm ≦550 | 200~ 400 | 0.15~0.23 0.13(t<6) 0.23 | 350×48Z 350×64Z 3.7(48Z) 4.3(64Z | Two Blades |

| CustomerD | φ114~ φ406 | 2~19mm ≦750 | 200~300 | 0.05~0.1 0.1~0.18 | 280×60Z 280×50Z 280×38Z 4.0 | Four Blades |

| CustomerE | ⟩250~ ⟩500 φ220~ φ660 | 3.5~22mm ≦650 | 200~ 300 | 0.05~0.1 0.1~0.18 | 360×48Z 360×40Z 360×34Z 4.0 | Four Blades |

| CustomerF | ⟩40~ ⟩150 φ42.7~ φ219 | 2.3~6mm | 200~ 400 | 0.05~0.23 0.23 | 350×48Z 360×40Z 4.1(48Z) 5.4(40Z) | Two Blades |

| CustomerG | ⟩200~ ⟩400 φ114.3~ φ508 | ~16mm | 300~ 400 | 0.05(Pipe) 0.15~0.23(Column) 0.13~0.19(Pipe) 0.13~0.21(Column) | 380×52Z 380×70Z 4.5 | Four Blades |

| CustomerH | ⟩150~ ⟩400 φ165.2~ φ406.4 | 2.3~12.7mm STK, STKR ≦550 | 300~ 400 | 380×52Z 380×70Z 4.5 | Two Blades | |

| CustomerI | ⟩150~ ⟩400 | 6~16mm | 240 | 0.18 0.16 | 380×52Z 380×70Z 4.5 | Two Blades |

| CustomerJ | φ190~ φ609.4 | 3~19mm | 180~280 | 0.06~ 0.1 0.15~ 0.18 | 340×34Z 340×48Z 4.3 | Four Blades |

| CustomerK | φ139.7~ φ426 Seamless Pipe | 4~50 Carbon Steel, Alloy SUS ≦1125 | 50~220 | 0.15ma× | 430×54 5.3 6.0 | Two Blades |

| CustomerL | ~6inch | 2.3~12.7 | 400~850 | 0.15ma× | 320×52Z 320×64Z 320×72Z 3.1 | Two Blades |

| CustomerM | ~6inch | 2.3~9 | 700~1000 | 0.08ma× | 355×72Z 355×90Z 355×120Z 2.3 | Two Blades |

Related Products

-

NAGANO KEIKI CE16 Electronic Pressure Switch Construction

-

U_RD HCS-AS-CL series DC Current Sensor

-

Asahi Bagnall Cat.No.815 AY-H Pantograph

-

Organo ORGABEAT Series Composite Coolant Treatment Agent

-

Gentos BL-350MG Dry Battery Bike Light (80lm / 1400cd)

-

Showa Measuring Instruments Resin Coated Copper Wire Gauge