Japan, Techno Aoyama

Techno Aoyama Stud Bolt Feeder

Product made in Japan

Manufacturer : Techno Aoyama

Model : Stud Bolt Feeder

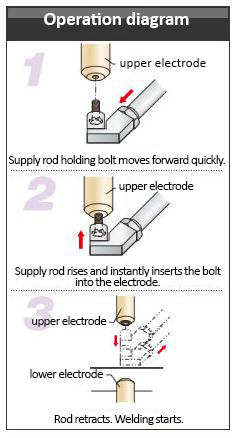

Stud bolt welding is changed from arc to resistance welding to dramatically improve welding quality. It is already in operation at body factories and parts factories around the world, contributing to quality improvement and cost reduction. A unique electrode water cooling system reduces running costs, and a bolt detection device inside the electrode prevents missing bolts. (International patented product) There are a wide variety of variations, from the standard stationary installation and robot process, to the compact horizontal feed type that can be incorporated into a dedicated machine, and the smart that can be attached to a C gun, to meet various needs.

Specifications

stud bolt supply head

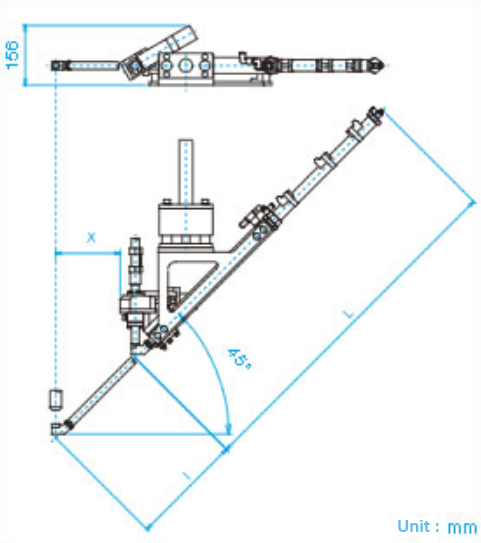

| stroke | L. | I | X |

| 200 | 825 | 195 | 100 |

| 250 | 875 | 245 | 135 |

| 300 | 925 | 295 | 170 |

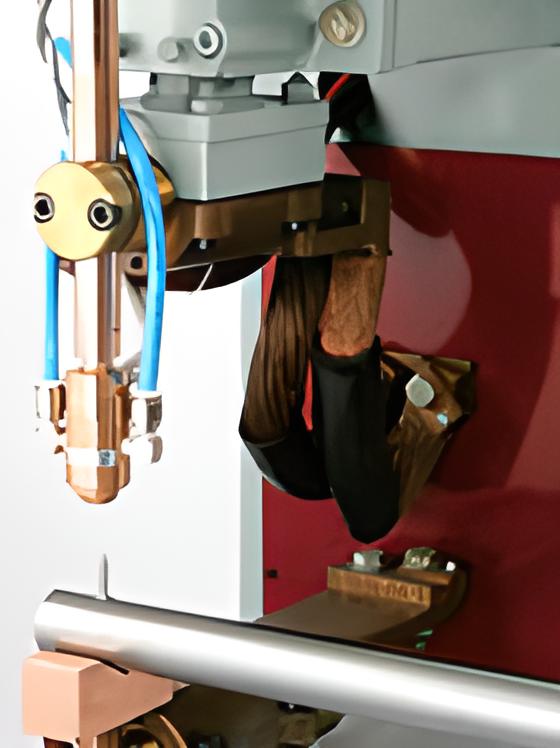

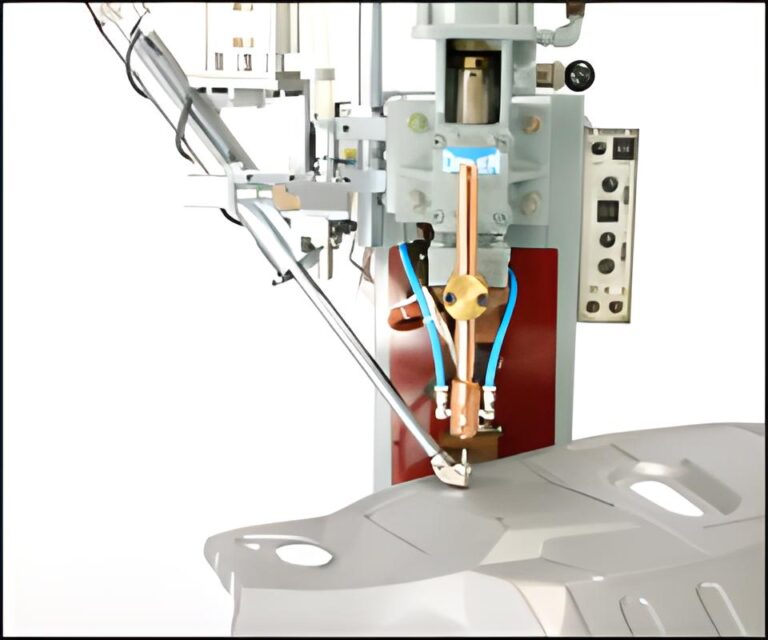

Working example

The panel is being brought in by a robot and the bolts supplied to the upper electrode are about to be joined. Bolts can be supplied even while the panel is moving, so the process time can be shortened. In addition, since the slim head ensures a sufficient stroke, the loading space is large and teaching is easy (the supply head can be mounted on either the left or right side). In addition, since the bolt holding part is equipped with a speed control device that protects the bolt holding part from the impact of the air-fed bolt, the holding part also has a long life.

Mounting list

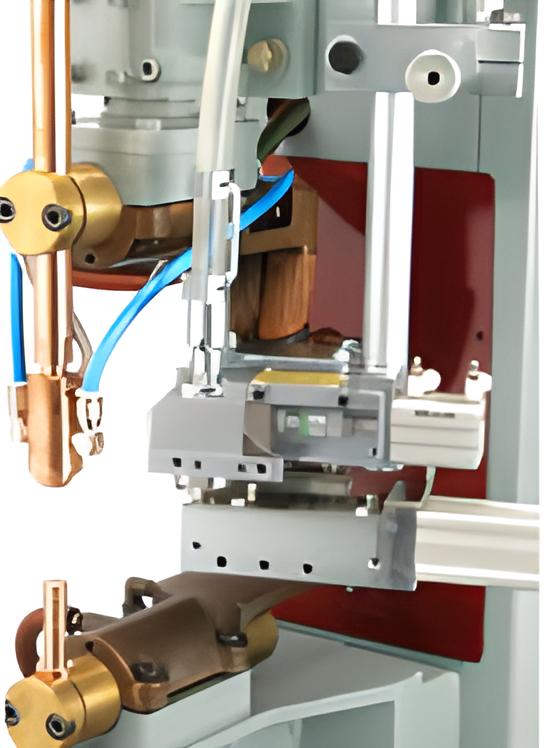

Horizontal feed type

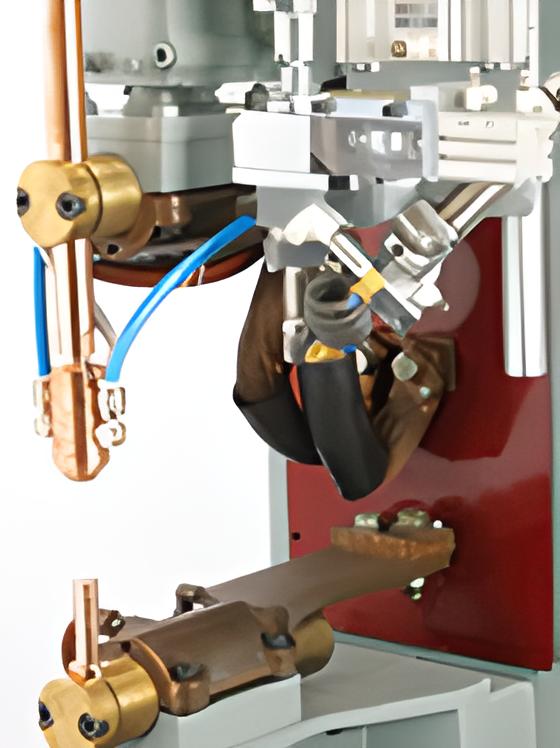

Smart A

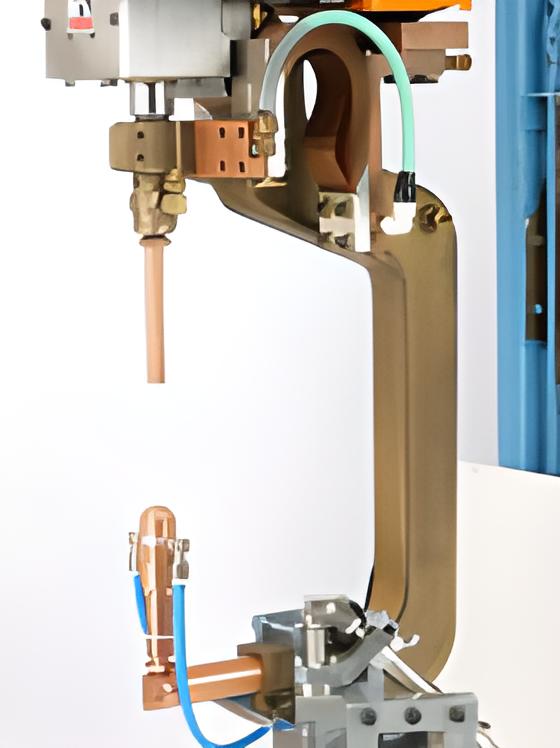

Smart B (C gun installation example)

Weldable on pipes