Fukuda Seiko, Japan

Fukuda Spectra ONE process monitoring system SPECTRA

Made in Japan

Manufacturer: Fukuda Seiko

Model: Spectra ONE

Features

The range of monitoring systems from the German-based Montronix company offers optimal solutions for various maintenance requirements such as tool and process monitoring, condition diagnostics and machine protection. Combine our powerful HMI software with Montronix products for tool and process monitoring.

- In-process monitoring

- Wide range of parameters to be measured – vibration, power, load, torque, AE

- Suitable for tools with a diameter of less than 3 mm

use

- Detection of tool breakage and tool wear

- Quantification of process quality

- Optimization of recipes and recipe cycles

- Determining when to replace tools

- Examples of applicable processes: Cutting, grinding, turning, drilling

in-process monitoring system SPECTRA

Montronix’s SPECTRA tool and process monitoring system is used in a wide range of metalworking applications. Various machining processes such as cutting, grinding, turning, drilling, etc. can be monitored.

By detecting and diagnosing problems that occur during machining in-process, factory troubles such as the outflow of machining defective lots and downtime are minimized.

A wide range of applications can be monitored

Application Examples

| Drilling/Cutting | Turning | grinding | Conveying system |

- A wide variety of measurement parameters (vibration, power, load, torque, AE) cover the monitoring of various machining processes

- It can also be used with small diameter tools with a diameter of less than 3 mm

For detecting various process abnormalities

- Tool abnormalities – breakage, wear, poor grip, etc.

- Accidental collision with the workpiece

- Detection of microcavities and impurity structures in materials

- Quality monitoring of threading processes

For process optimization

- In-process detection of out-of-tolerance quality deviations during machining

- Processing quality can be quantified

- Based on quantified data, recipes and recipe cycles can be optimized

Also for machine protection

- Detects unforeseen collisions between the tool and the workpiece

- Detects overload during machining

- By quickly protecting equipment from collisions and overloads, it contributes to improving equipment utilization and reducing various costs related to damage to equipment and equipment parts and the occurrence of defective lots

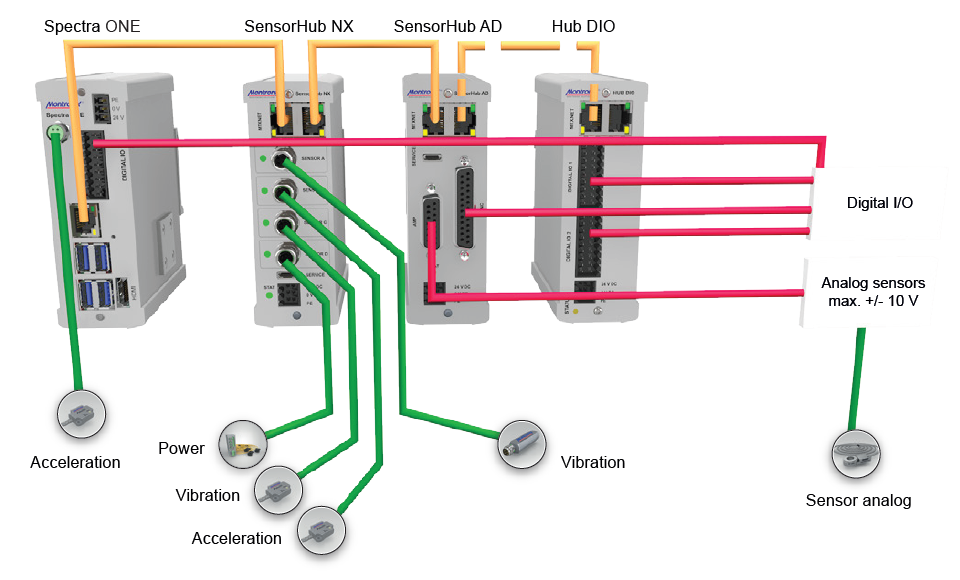

Scalable System Components

* Configurations are examples only

* Configurations are examples only

Spectra ONE

SPECTRA system central control box for tool and process monitoring.

- Built-in discrete I/O (expandable with Hub DIO)

- Fieldbus communication via Profibus and Profinet

- Dedicated hubs (analog: SensorHub AD, digital: SensorHub NX) can be used to expand the number of sensor handling.

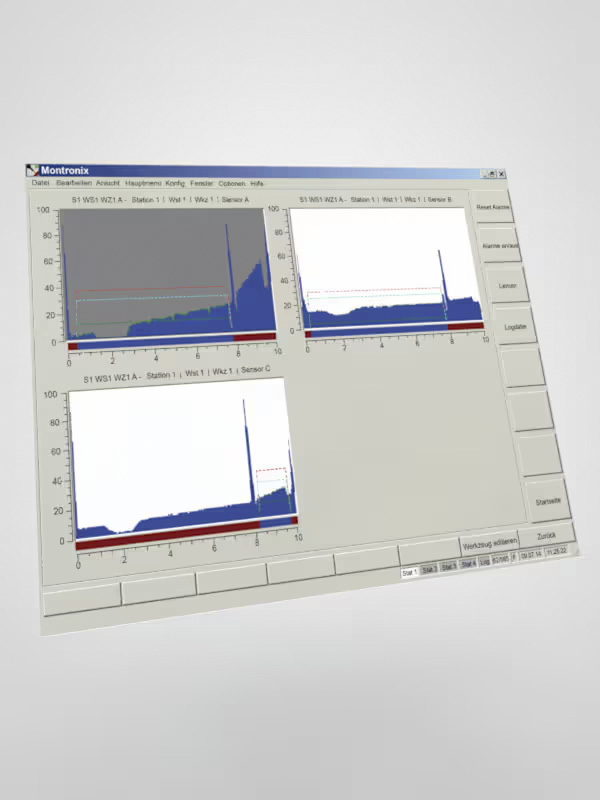

Dedicated software SPECTRA-hmi

Graphical software dedicated to the SPECTRA system that runs on machine controllers running on Microsoft Windows and on the dedicated display device SPECTRA Vision.

- Up to 12 sensor monitoring windows can be set

- Manage user/operator privileges with 6 levels of access

- Microsoft Windows: XP, VISTA, 7, 8, 10 (can be conditionally installed on Windows NT4, Windows 2000, and some Linux distributions)