Japan, Matsumoto Kikai

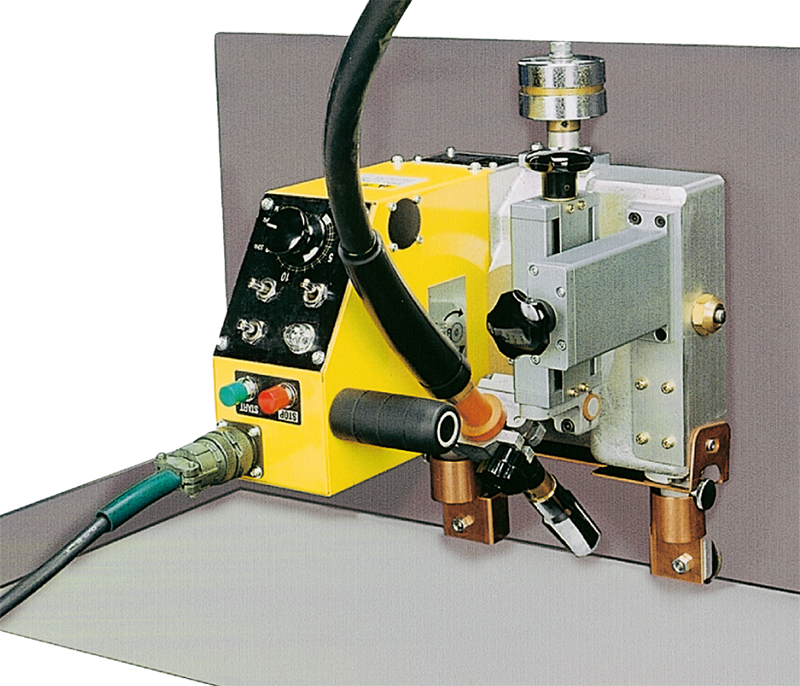

Matsumoto Kikai HC-140D Welding Trolley

Product Made in Japan

Manufacturer : Matsumoto Kikai

Model : HC-140D

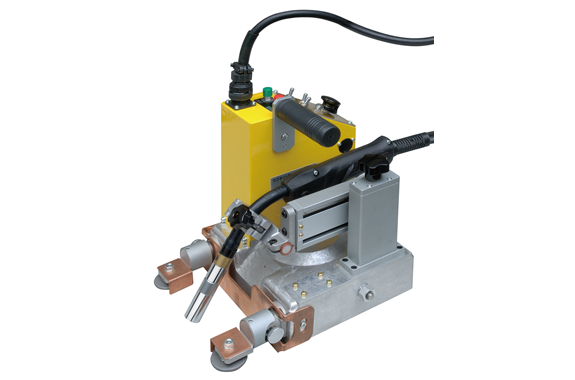

Matsumoto Kikai’s handy carriage “Sumiko I-D type” is a welding carriage ideal for horizontal fillet welding in shipbuilding and bridge construction. It is compact and lightweight and can be easily operated by anyone.

Small size and light weight

The main body weight is 9.4 kg, making it easy to carry.

Great traction!

Sufficient pulling power to pull the welding torch (conduit cable 5M) is provided by the attractive force of the electromagnet inside the main body and the four-wheel driving force of the rubber wheels.

You can run round trip!

Welding can be carried out on either the right or left side simply by adjusting the vertical plate following guide rollers.

Outstanding operability!

The operation panel is simple and easy to use, and the automatic stop function allows one person to use multiple units.

Wide range of torch adjustment!

Equipped with a robust mount with a long stroke, the torch aiming position can be finely adjusted over a wide range both vertically and forwards. You can also use your own semi-automatic torch, and if you use a dedicated straight torch, you can set it in the holder with one touch, so it has excellent reproducibility of the aiming position. (Holders are available for automatic (φ20) and semi-automatic (φ17).)

Perfect against spatter!

Heat-resistant rubber wheels are used for the drive wheels in the internal structure of the main body. In addition, since a protective cover is attached to the guide roller on the torch side of the trolley, there is no trouble caused by spatter.

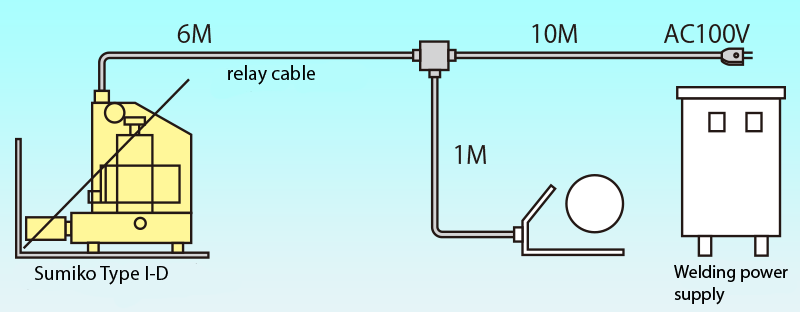

■ Configuration diagram

Specifications

| name | Sumikko ID type |

|---|---|

| Model | HC-140D |

| Carriage drive system | Four-wheel drive with built-in rubber wheels and electromagnets for attraction |

| Carriage tracking method | Guide roller vertical plate copying (semi-fixed type) |

| Traction force (magnet clearance) | 15kgf (3mm) / 25kgf (2mm) |

| Bogie speed adjustment range | 100 to 1300mm/min (50Hz) 100 to 1500mm/min (60Hz) |

| Torch adjustment range | Horizontal 50mm Vertical 50mm |

| Torch angle adjustment range | 45° +3°/-1.8° dedicated straight torch |

| Automatic stop function | Available (Both direction limit switch type) |

| Operation function | Power ON/OFF, travel direction (left/right) selection, speed regulator, arc ON/ welding interlock selection, welding start, welding stop |

| Crater processing function | none |

| Welding residue | Start 113mm / End 132mm |

| Control input power | AC1φ 100V 50/60Hz |

| Relay control cable length | 6M (with 7P metal outlet) |

| Torch switch cable length | 1M (2 cores) 1 system |

| power cable length | 10M |

| External dimensions (W×L×H) | 275×246×255mm |

| Bogie body mass | 9.4kg |

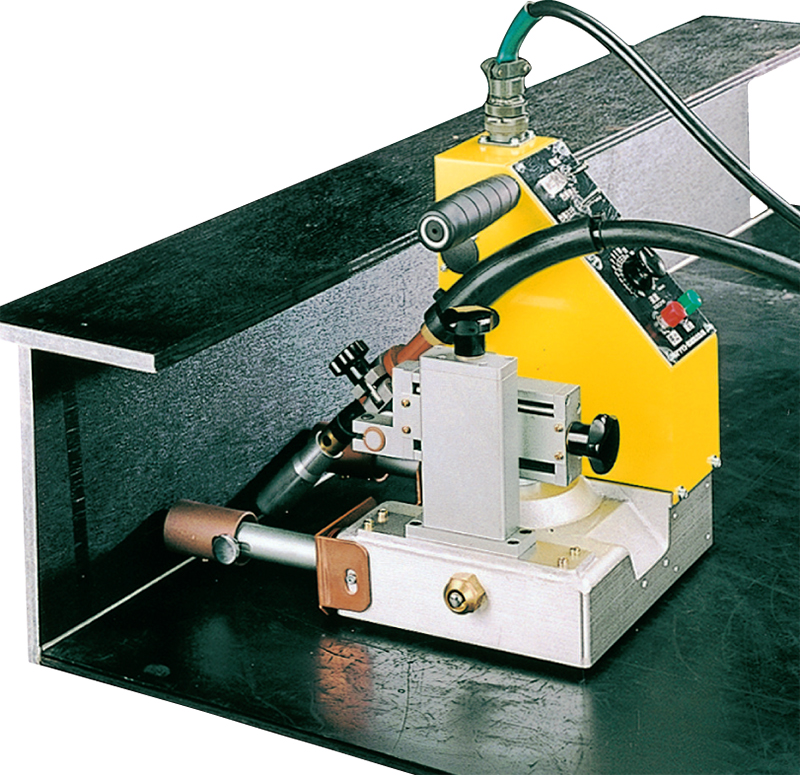

2-electrode welding type

2-electrode type I-DW

●Welding is possible with 2 electrodes (both fillets at the same time).

*Rib height up to 300mm

Optional

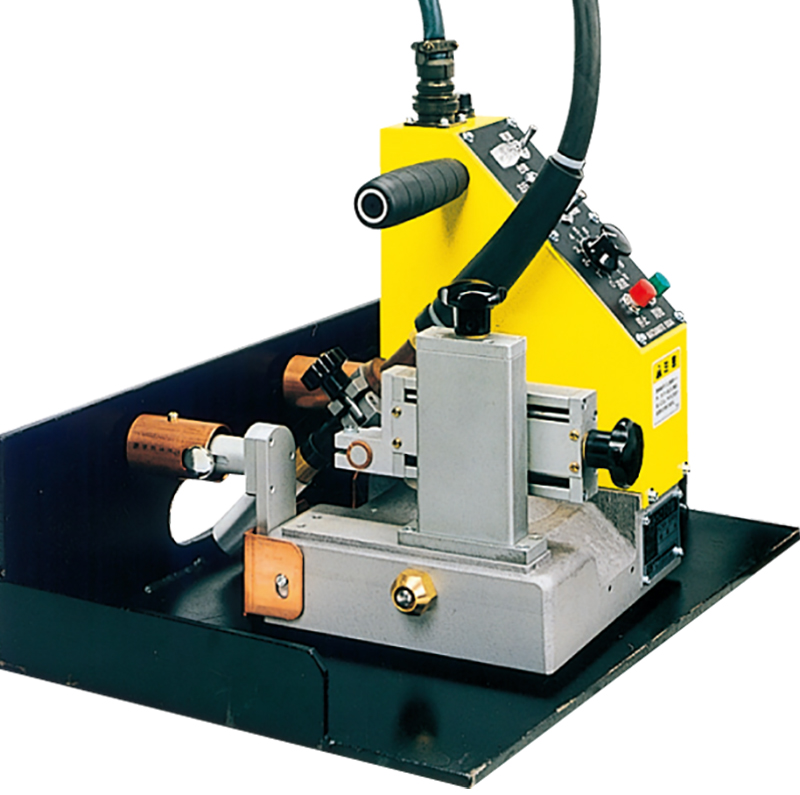

Outer guide roll

●Used when there are no vertical ribs, such as square boxes.

drain plate

●Attach a plate (1 set of 2) between the main body and the guide roller so as to follow the upper part.

* Copying height 93mm (standard is 33mm)

long guard frame

● Fillet welding of T-rib and bottom plate.

Magnet roll for running vertical plate

● Welding while moving the vertical plate. A permanent magnet roller is attached to prevent falling off.