Japan, MAXPULL

Maxpull BMW three-phase 200V dog clutch series

Product made in Japan

Manufacturer: Maxpull

Model: BMW-201-SC type/BMW-202-SC type/BMW-203-SC type/BMW-301-SC type/BMW-302-SC type/BMW-303-SC type/BMW-401-SC type/BMW -402-SC type/BMW-403-SC type/BMW-501-SC type/BMW-502-SC type/BMW-503-SC type

Features

An electric winch with a dog clutch suitable for frequent wire rope unwinding operations.

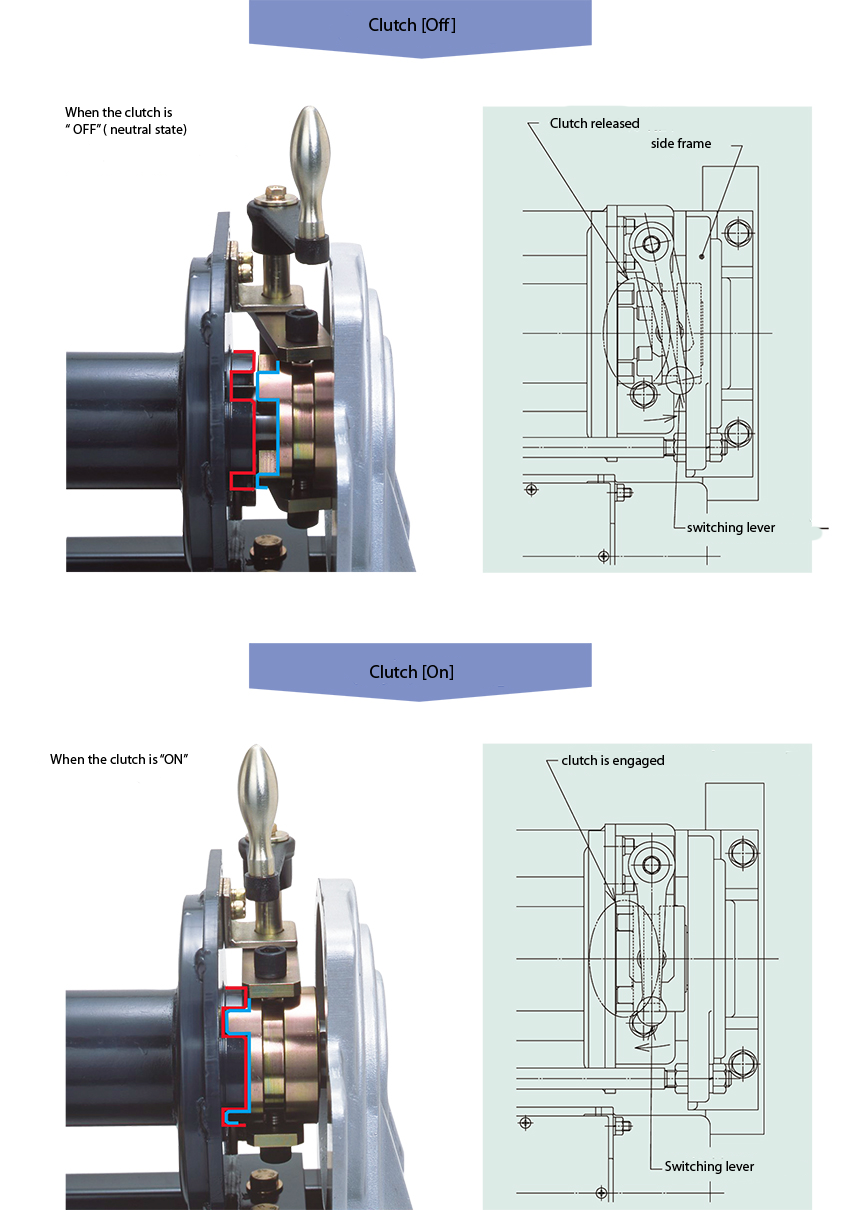

●With a simple operation of a single lever, the drum is in a neutral state and the wire rope can be easily pulled out.

●Clutch operation is light, easy and reliable due to its precise design.

●The built-in motor is compact and has an excellent design.

●Can be used with industrial three-phase 200V.

BMW dog clutch series

This is a mesh type winch standardized by adding a clutch to the rotating BMW series. A simple operation of a single lever puts the drum into a light neutral state. In addition, the sophisticated design makes the clutch on light and reliable. Since no rotational load is applied to the motor or reduction gear, it is easy to unwind the wire.

Parallel type winch with built-in motor

This is an electric winch with a built-in motor and drum built in parallel. The precision-designed reduction gear allows the electric drive to work directly, providing strong and stable traction. The gear case, etc. is made of aluminum alloy casting with a special heat treatment, making it much lighter and smaller than conventional products. In addition, it is dustproof, rustproof, and rainproof, and can be installed in a small space. The power supply is AC 100V.

●Since it is a parallel type with two rows of motor and drum parts, it is compact and can be installed in a narrow space without taking up much space.

● The motor, speed reduction mechanism, electromagnetic brake, etc., which are the heart of the product, are rust-resistant and lightweight aluminum alloy castings that are safe against rain, wind, and dust.

●High-performance electromagnetic brakes are used, so the braking force is extremely high, demonstrating power even in delicate work.

●The wire rope can be easily and securely installed by passing the wire rope through the two wire holes in the drum pipe and tightening the fasteners.

Clutch “off”, “on”

Specifications

| model | BMW-201-SC type | BMW-202-SC type | BMW-203-SC type | BMW-301-SC type | BMW-302-SC type | BMW-303-SC type | BMW-401-SC type | BMW-402-SC type | BMW-403-SC type | BMW-501-SC type | BMW-502-SC type | BMW-503-SC type | ||||||||||||

| frequency | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz |

| wire rope tensile force | 1st layer: 1274N (130kgf) 3rd layer: 1274N (130kgf) 5th layer: 1078N (110kgf) | 1st layer: 1078N (110kgf) 3rd layer: 1078N (110kgf) 5th layer: 882N (90kgf) | 1st layer: 2058N (210kgf) 3rd layer: 2058N (210kgf) 5th layer: 1764N (180kgf) | 1st layer: 1764N (180kgf) 3rd layer: 1764N (180kgf) 5th layer: 1470N (150kgf) | 1st layer: 3234N (330kgf) 3rd layer: 3234N (330kgf) 5th layer: 2744N (280kgf) | 1st layer: 2646N (270kgf) 3rd layer: 2646N (270kgf) 5th layer: 2254N (230kgf) | 1st layer: 2450N (250kgf) 3rd layer: 2450N (250kgf) 5th layer: 2058N (210kgf) | 1st layer: 2058N (210kgf) 3rd layer: 2058N (210kgf) 5th layer: 1666N (170kgf) | 1st layer: 3920N (400kgf) 3rd layer: 3920N (400kgf) 5th layer: 3234N (330kgf) | 1st layer: 3234N (330kgf) 3rd layer: 3234N (330kgf) 5th layer: 2744N (280kgf) | 1st layer: 5684N (580kgf) 3rd layer: 5684N (580kgf) 5th layer: 4606N (470kgf) | 1st layer: 4704N (480kgf) 3rd layer: 4704N (480kgf) 5th layer: 3822N (390kgf) | 1st layer: 6272N (640kgf) 3rd layer: 6272N (640kgf) 5th layer: 4998N (510kgf) | 1st layer: 5194N (530kgf) 3rd layer: 5194N (530kgf) 5th layer: 4214N (430kgf) | 1st layer: 8820N (900kgf) 3rd layer: 8820N (900kgf) 5th layer: 6958N (710kgf) | 1st layer: 7546N (770kgf) 3rd layer: 7546N (770kgf) 5th layer: 5978N (610kgf) | 1st layer: 9800N (1000kgf) 3rd layer: 9800N (1000kgf) 5th layer: 7742N (790kgf) | 1st layer: 8820N (900kgf) 3rd layer: 8820N (900kgf) 5th layer: 6958N (710kgf) | 1st layer: 8820N (900kgf) 3rd layer: 8820N (900kgf) 5th layer: 6958N (710kgf) | 1st layer: 7350N (750kgf) 3rd layer: 7350N (750kgf) 5th layer: 5782N (590kgf) | 1st layer: 11760N (1200kgf) 3rd layer: 11760N (1200kgf) 5th layer: 9114N (930kgf) | 1st layer: 9800N (1000kgf) 3rd layer: 9800N (1000kgf) 5th layer: 7644N (780kgf) | 1st layer: 12740N (1300kgf) 3rd layer: 12740N (1300kgf) 5th layer: 9800N (1000kgf) | 1st layer: 11270N (1150kgf) 3rd layer: 11270N (1150kgf) 5th layer: 8820N (900kgf) |

| Winding speed | 1st layer: 10.8 m/min 3rd layer: 13.5 m/min 5th layer: 16.2 m/min | 1st layer: 12.9 m/min 3rd layer: 16.1 m/min 5th layer: 19.4 m/min | 1st layer: 6.7 m/min 3rd layer: 8.4 m/min 5th layer: 10.1 m/min | 1st layer: 8.0 m/min 3rd layer: 10.1 m/min 5th layer: 12.1 m/min | 1st layer: 4.4 m/min 3rd layer: 5.5 m/min 5th layer: 6.6 m/min | 1st layer: 5.2 m/min 3rd layer: 6.6 m/min 5th layer: 7.9 m/min | 1st layer: 10.6 m/min 3rd layer: 13.3 m/min 5th layer: 16.0 m/min | 1st layer: 12.7 m/min 3rd layer: 15.9 m/min 5th layer: 19.1 m/min | 1st layer: 6.6 m/min 3rd layer: 8.3 m/min 5th layer: 10.0 m/min | 1st layer: 7.9 m/min 3rd layer: 9.9 m/min 5th layer: 11.9 m/min | 1st layer: 4.4 m/min 3rd layer: 5.9 m/min 5th layer: 7.3 m/min | 1st layer: 5.3 m/min 3rd layer: 7.0 m/min 5th layer: 8.7 m/min | 1st layer: 7.8 m/min 3rd layer: 10.6 m/min 5th layer: 13.5 m/min | 1st layer: 9.3 m/min 3rd layer: 12.7 m/min 5th layer: 16.1 m/min | 1st layer: 5.1 m/min 3rd layer: 6.9 m/min 5th layer: 8.8 m/min | 1st layer: 6.1 m/min 3rd layer: 8.3 m/min 5th layer: 10.5 m/min | 1st layer: 4.3 m/min 3rd layer: 5.9 m/min 5th layer: 7.4 m/min | 1st layer: 5.1 m/min 3rd layer: 7.0 m/min 5th layer: 8.9 m/min | 1st layer: 7.7 m/min 3rd layer: 10.5 m/min 5th layer: 13.4 m/min | 1st layer: 9.2 m/min 3rd layer: 12.6 m/min 5th layer: 16.1 m/min | 1st layer: 5.1 m/min 3rd layer: 7.1 m/min 5th layer: 9.2 m/min | 1st layer: 6.1 m/min 3rd layer: 8.5 m/min 5th layer: 11.0 m/min | 1st layer: 4.3 m/min 3rd layer: 6.0 m/min 5th layer: 7.8 m/min | 1st layer: 5.2 m/min 3rd layer: 7.2 m/min 5th layer: 9.3 m/min |

| Wire rope capacity | 1st layer: φ6×7.0m 3rd layer: φ6×23.6m 5th layer: φ6×43.8m | 1st layer: φ6×7.0m 3rd layer: φ6×23.6m 5th layer: φ6×43.8m | 1st layer: φ6×7.0m 3rd layer: φ6×23.6m 5th layer: φ6×43.8m | 1st layer: φ6×7.0m 3rd layer: φ6×23.6m 5th layer: φ6×43.8m | 1st layer: φ6×7.0m 3rd layer: φ6×23.6m 5th layer: φ6×43.8m | 1st layer: φ8×5.5m 3rd layer: φ8×19.2m 5th layer: φ8×36.5m | 1st layer: φ9×5.8m 3rd layer: φ9×20.7m 5th layer: φ9×39.8m | 1st layer: φ9×5.8m 3rd layer: φ9×20.7m 5th layer: φ9×39.8m | 1st layer: φ9×5.8m 3rd layer: φ9×20.7m 5th layer: φ9×39.8m | 1st layer: φ9×5.8m 3rd layer: φ9×20.7m 5th layer: φ9×39.8m | 1st layer: φ10×5.3m 3rd layer: φ10×19.2m 5th layer: φ10×37.4m | 1st layer: φ10×5.3m 3rd layer: φ10×19.2m 5th layer: φ10×37.4m | ||||||||||||

| Applicable wire rope | φ6mm (6×37) (JIS standard) | φ6mm (6×37) (JIS standard) | φ6mm (6×37) (JIS standard) | φ6mm (6×37) (JIS standard) | φ6mm (6×37) (JIS standard) | φ8mm (6×37) (JIS standard) | φ9mm (6×37) (JIS standard) | φ9mm (6×37) (JIS standard) | φ9mm (6×37) (JIS standard) | φ9mm (6×37) (JIS standard) | φ10mm (6×37) (JIS standard) | φ10mm (6×37) (JIS standard) | ||||||||||||

| Reduction ratio | 1/40.3 | 1/64.5 | 1/99 | 1/40.3 | 1/64.5 | 1/99 | 1/57.2 | 1/87.5 | 1/103.3 | 1/57.2 | 1/87.5 | 1/103.3 | ||||||||||||

| Motor type | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | Totally enclosed self-cooling type: built-in motor | ||||||||||||

| output | 0.4 kW | 0.4 kW | 0.4 kW | 0.75 kW | 0.75 kW | 0.75 kW | 1.5 kW | 1.5 kW | 1.5 kW | 2.2 kW | 2.2 kW | 2.2 kW | ||||||||||||

| number of poles | 4P | 4P | 4P | 4P | 4P | 4P | 4P | 4P | 4P | 4P | 4P | 4P | ||||||||||||

| Voltage current | Three-phase AC200V 50Hz 2.2A | Three-phase AC200V 60Hz 1.9A | Three-phase AC200V 50Hz 2.2A | Three-phase AC200V 60Hz 1.9A | Three-phase AC200V 50Hz 2.2A | Three-phase AC200V 60Hz 1.9A | Three-phase AC200V 50Hz 3.6A | Three-phase AC200V 60Hz 3.2A | Three-phase AC200V 50Hz 3.6A | Three-phase AC200V 60Hz 3.2A | Three-phase AC200V 50Hz 3.6A | Three-phase AC200V 60Hz 3.2A | Three-phase AC200V 50Hz 6.4A | Three-phase AC200V 60Hz 5.9A | Three-phase AC200V 50Hz 6.4A | Three-phase AC200V 60Hz 5.9A | Three-phase AC200V 50Hz 6.4A | Three-phase AC200V 60Hz 5.9A | Three-phase AC200V 50Hz 9.3A | Three-phase AC200V 60Hz 8.5A | Three-phase AC200V 50Hz 9.3A | Three-phase AC200V 60Hz 8.5A | Three-phase AC200V 50Hz 9.3A | Three-phase AC200V 60Hz 8.5A |

| insulation | Class B | Class B | ||||||||||||||||||||||

| break | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | Spring-close type electromagnetic brake | ||||||||||||

| brake braking rate | 150% or more | 150% or more | ||||||||||||||||||||||

| load time rate | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | 40% ED | ||||||||||||

| Control method | Direct operation by 2-point push button switch (operation cable 2mm2 x 4 cores x 2.5m, power cable 2mm2 x 4 cores x 2.5m) | Direct operation by 2-point push button switch (operation cable 2mm2 x 4 cores x 2.5m, power cable 2mm2 x 4 cores x 2.5m) | ||||||||||||||||||||||

| dead weight | 47.3kg | 47.6kg | 49.5kg | 48.4kg | 48.7kg | 50.4kg | 64.2kg | 65.7kg | 67.0 kg | 68.4kg | 68.7kg | 70.0 kg | ||||||||||||

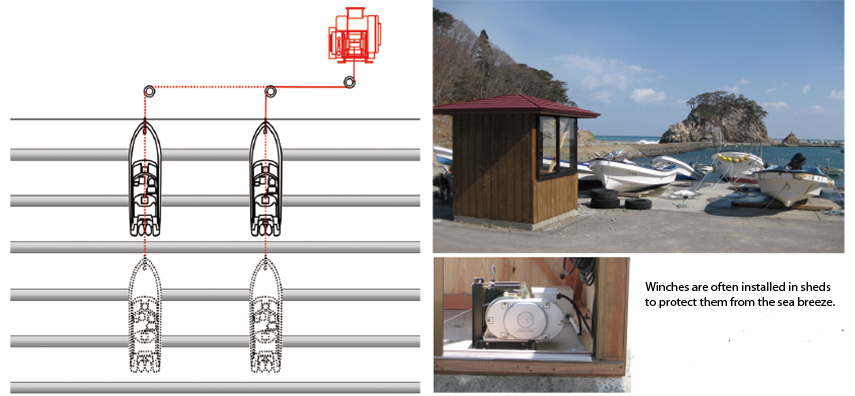

Winch use site & wire rotation

When the ship returns to port, the wire rope can be pulled out quickly to unload the ship.