In the case of ceramic lining, 24 hours hardening (20 ℃) is recommended.

In the case of ceramic lining, 24 hours hardening (20 ℃) is recommended.

Products Made in Japan

Manufacturer: Toyo Mic

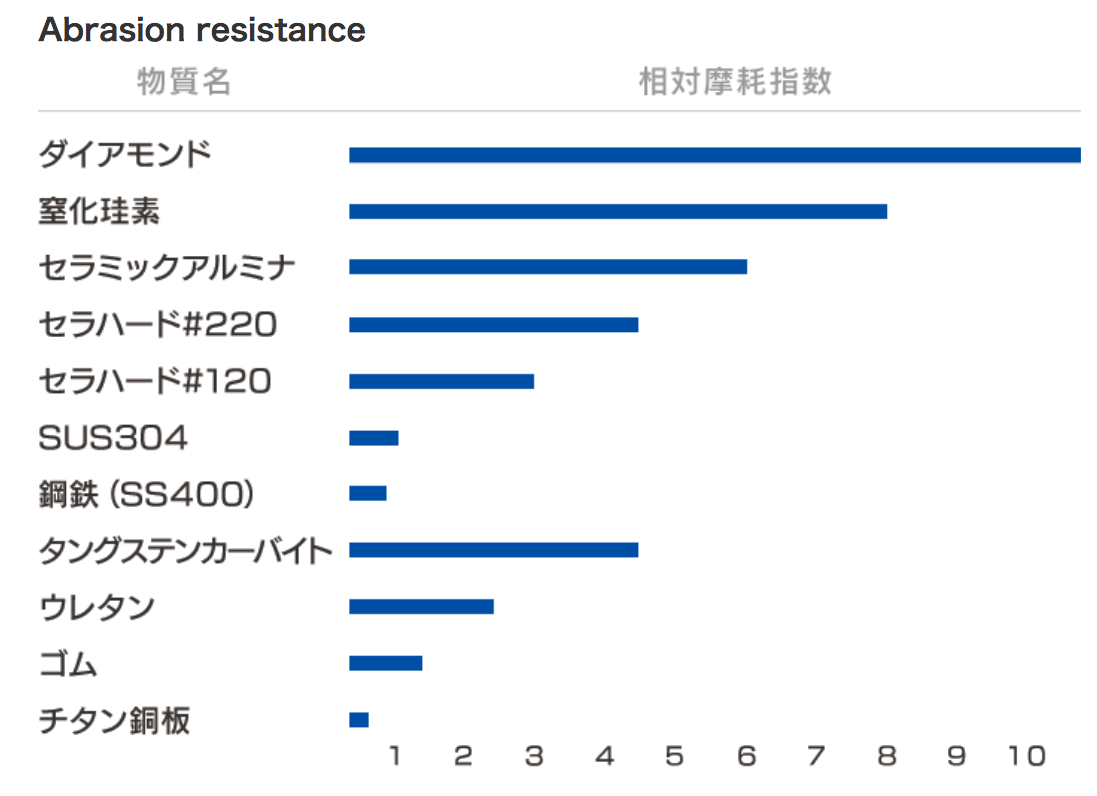

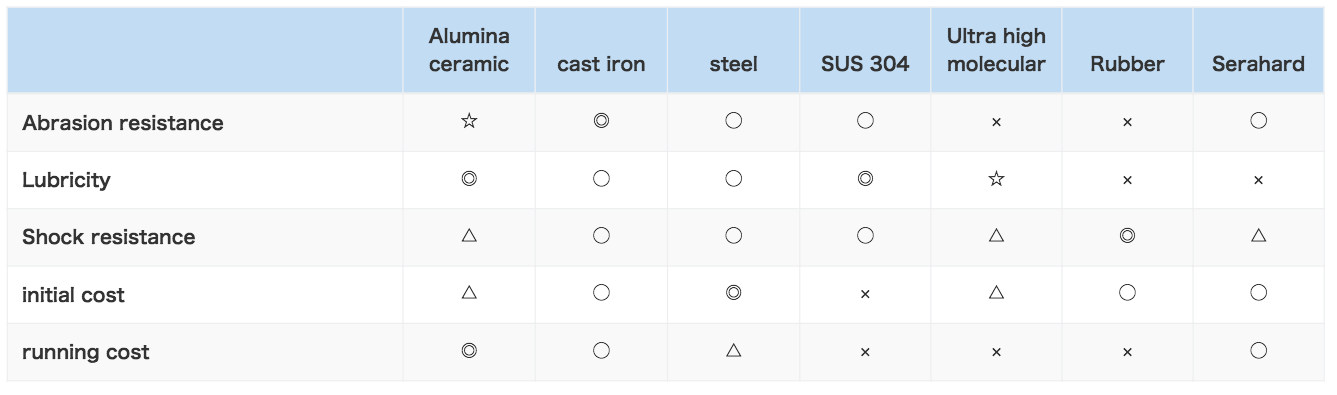

The characteristics comparison between many wear resistant liners including ceramic, cast iron, steel and stainless steel 304 (SUS), etc is shown in the table below

☆ It is most excellent ◎ Excellent ◯ Good △ Problemed X Inappropriate

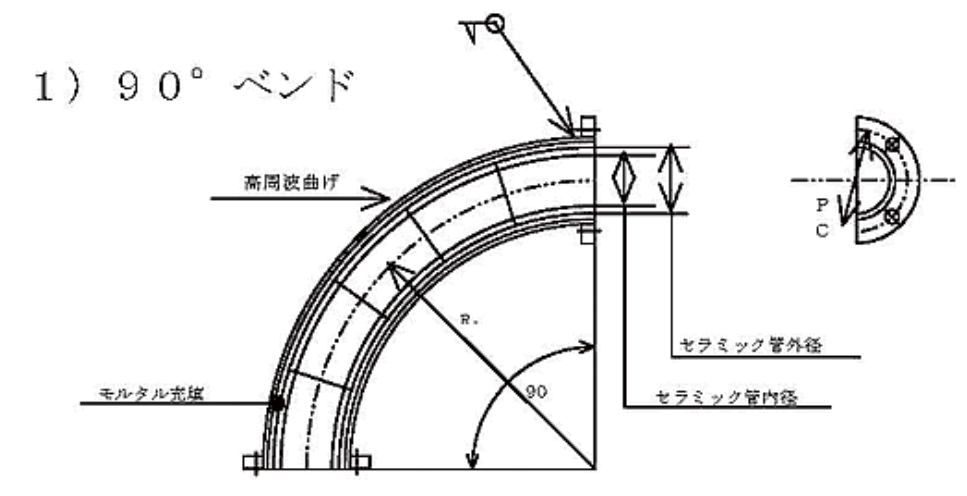

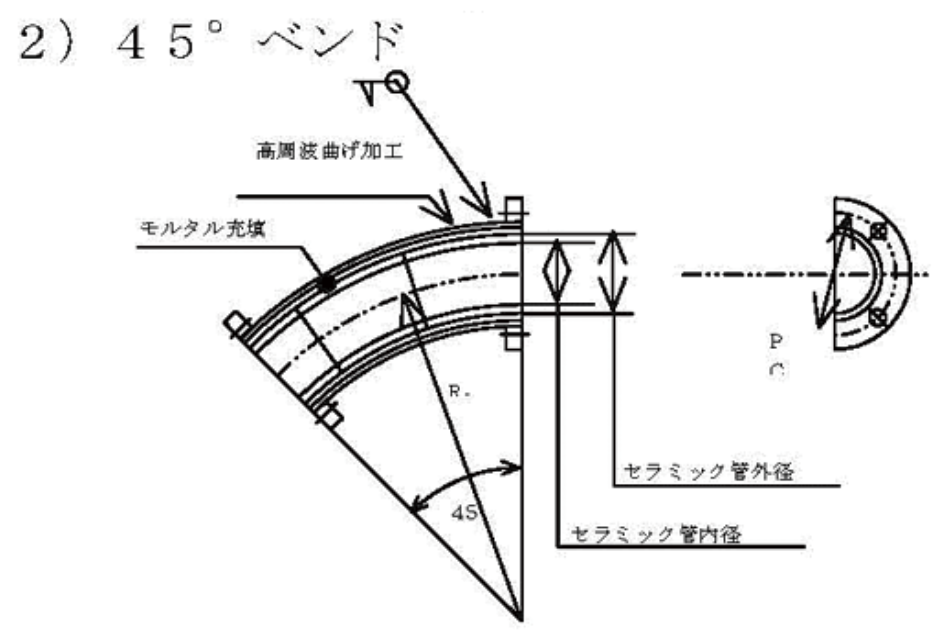

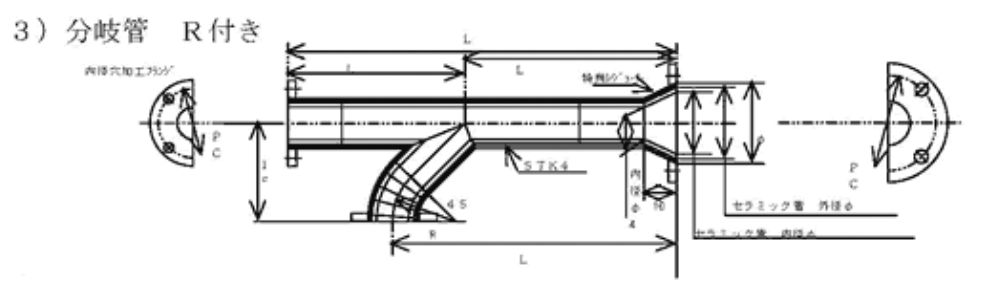

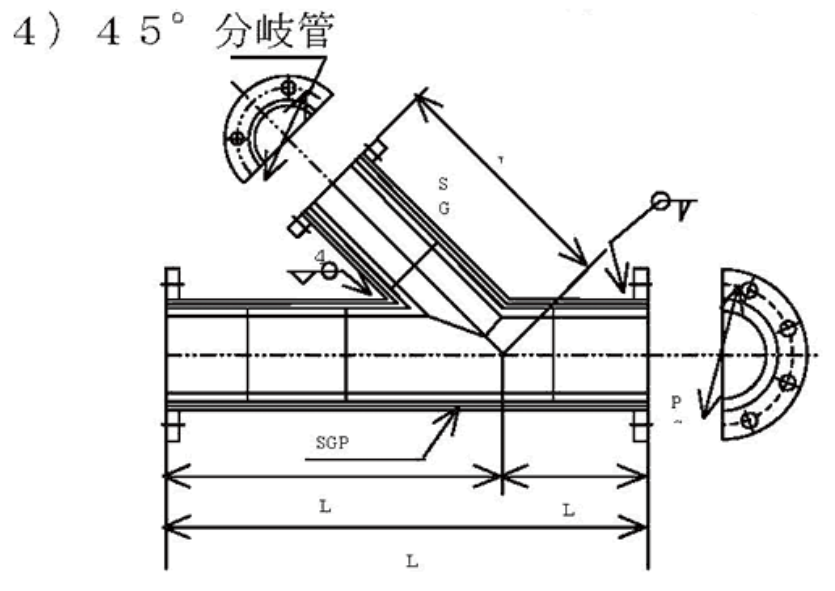

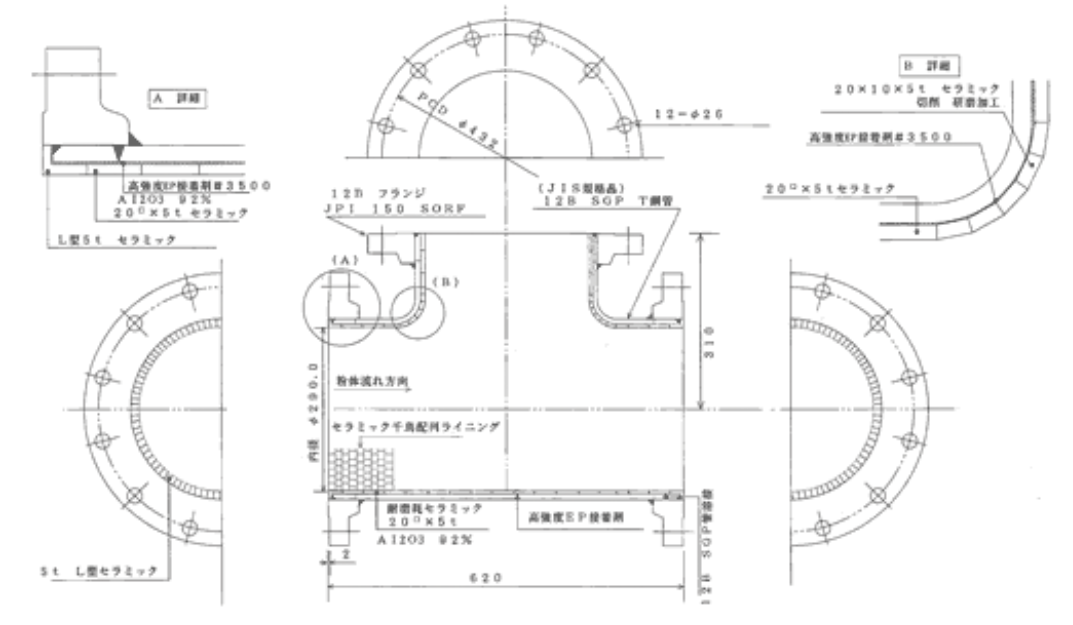

· In case of curved pipe, it can be manufactured from 10 A to 400 A

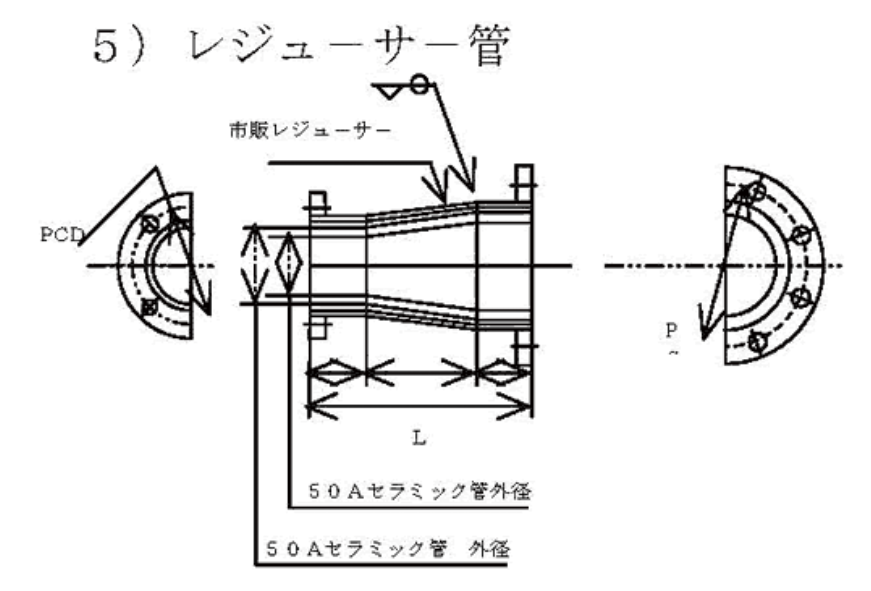

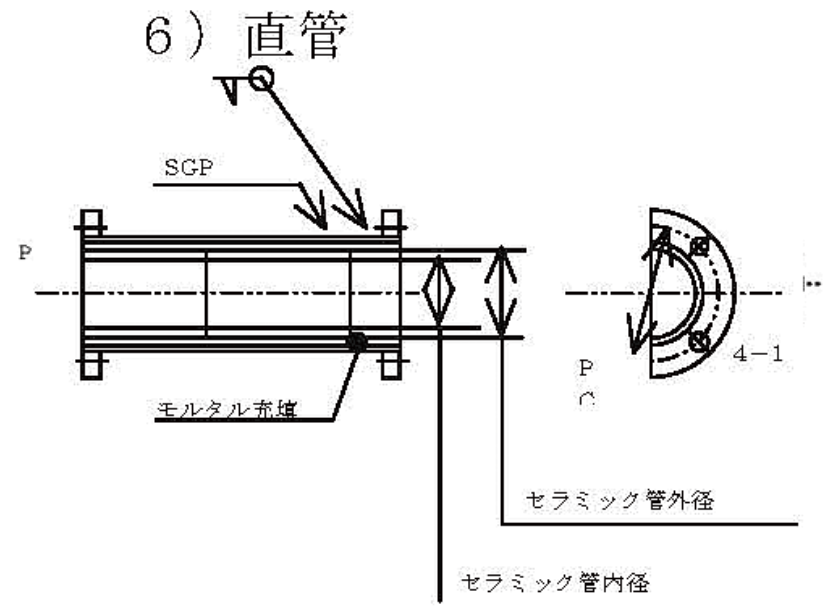

· In the case of ceramic lining, it is possible to produce from 100 A to requested size

· Various ceramic tubes can also be manufactured with flange size of connecting pipe and branched pipes

Advantages:

Disadvantages:

Advantages

Disadvantages

Knowledge of adhesive

Currently, it is difficult to attach ceramic to other materials. If the adhesives are mischosen, there will be a possibility that ceramic tiles can peel off or fall off due to poor adhesion. Currently, lining method with epoxy type II liquid is mainly used.

The main epoxy resin adhesives developed for ceramic lining are:

· Structbond type II liquid (A company)

· Arteco 3500 type II liquid (B company)

· Aikabond type II liquid (C company)

· Tilement type II liquid (D Company )

Hardness difference due to hardening time

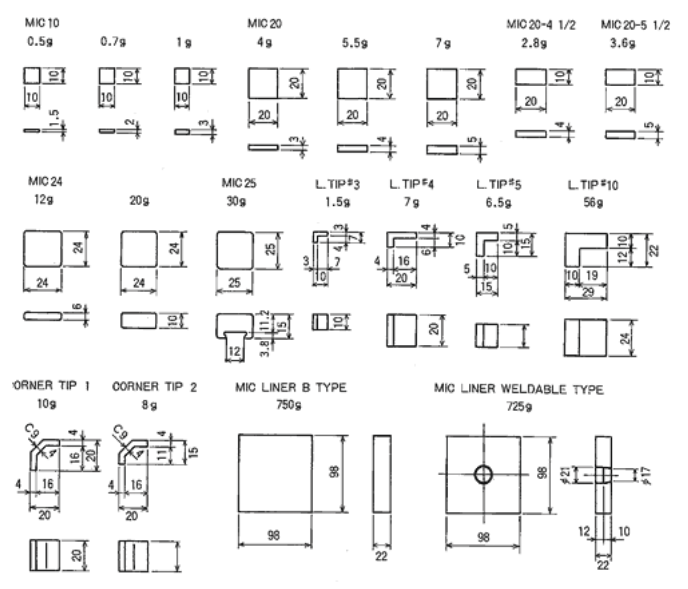

Ceramic tiles are chosen according to construction shape and application. They can be produced from 10 × 1.5 t to 100 × 25 t.

Ceramic tile shapes

Copyright © Kouei Japan Trading | Get Quotation