Bending, Japan, Ogura, Other Tools

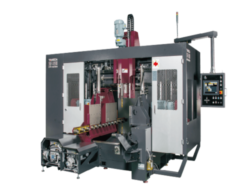

Ogura MB-819 Portable Rebar Bending Machine

Product Made in Japan

Manufacturer: Ogura

Model: MB-819

Features of MB-819

- Easy to use dial type for setting the bending angle. The angle can be set from 0 ° to 180 ° with a convenient angle fine adjustment lever.

- Isolates the processed and structural parts and shuts out the iron powder.

- Various bending processes are possible by combining rollers and collars.

- Use a foot switch to further improve workability (sold separately).

- Bending of small R is also possible by right angle bending collar (sold separately).

Specification of MB-819

| Motor | Single phase 100V 1050W 50 / 60Hz |

| Mass | 54.5kg |

| Body dimensions | 455 (L) x 372 (W) x 393 (H) mm |

| Maximum/minimum bending radius | For SD345 D8 (R69 to R15), D19 (R59 to R19.5) |

| Bending speed | 180 ° bending (approximately 5.0 seconds) |

| Number bent at a time | D19 (1), D16 (2), D13 (3), D10 (4) |

| Bending ability | Reinforcing bar diameter D8 to D19 (* SD490 equivalent: 620N / mm 2 (63kgf / mm 2 )) |

| Bending angle range | 4 steps up to 180 ° (with fine adjustment function) |

| Standard accessories | Roller (No.B19 · No.B16 · No.B13 · No.B10), Collar (No.19 · No.16 · No.13 · No.10), Hexagon wrench (2 · 17), Spanner (17 × 19), (+-) screwdriver, grounding adapter, toolbox, waterproof cover |

| Option | Footswitch, body stand, right angle bend collar (D10 · D13), auxiliary table |

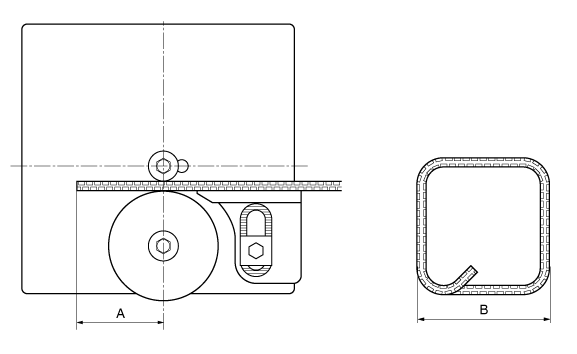

R & C TABLE (How to combine Roller and Collar)

Minimum necessary length of bending

Combination of Roller and Collar

| Rebar diameter | roller | Collar | A dimension (minimum) | ||

|---|---|---|---|---|---|

| 90 ° bend | 135 ° bending | 180 ° bending | |||

| D10 | B10 (Φ138) | B10 (Φ39) | 66mm | 86mm | 106mm |

| D13 | B13 (Φ118) | B13 (Φ52) | 84mm | 110mm | 136mm |

| D16 | B16 (Φ100) | B16 (Φ64) | 99mm | 131mm | 163mm |

| D19 | B19 (Φ80) | B19 (Φ76) | 118mm | 156mm | 194mm |

| Rebar diameter | Collar | B dimension (minimum) |

|---|---|---|

| D10 | B10 (Φ39) | 132mm |

| D13 | B13 (Φ52) | 151mm |

| D16 | B16 (Φ64) | 169mm |